Method for separating glutamic acid and lactic acid from fermentation waste liquor by packed bed electrodialysis

A technology of packed bed electrodialysis and fermentation waste liquid, applied in electrodialysis, chemical instruments and methods, separation/purification of carboxylic acid compounds, etc., can solve the problems of lack of effective methods, etc., and achieve the effect of promoting engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1 Conventional electrodialysis is used for the separation of glutamic acid and lactic acid in fermentation waste liquid

[0071] Firstly, conventional electrodialysis was used to separate glutamic acid and lactic acid in fermentation waste liquid. The conventional electrodialysis desalination membrane stack has 3 positive membranes, and 2 negative membranes are alternately arranged between the cathode and anode plates, forming 2 concentrated chambers and 2 dilute chambers. The separator between the membranes is a double-layer woven mesh separator, and the thickness of each compartment is 0.9mm. The anode plate is made of titanium coated with ruthenium, and the cathode plate is made of stainless steel; operating conditions: the dilute chamber is 2g / L L-lac- and L-glu-mixture, the circulation flow rate is 50L / h; the concentrated chamber is 50mg / L Na 2 SO-4, 0.1% Na in the pole chamber 2 SO 4 , the circulation flow rate is 40L / h, the solution in each chamber is ...

Embodiment 2

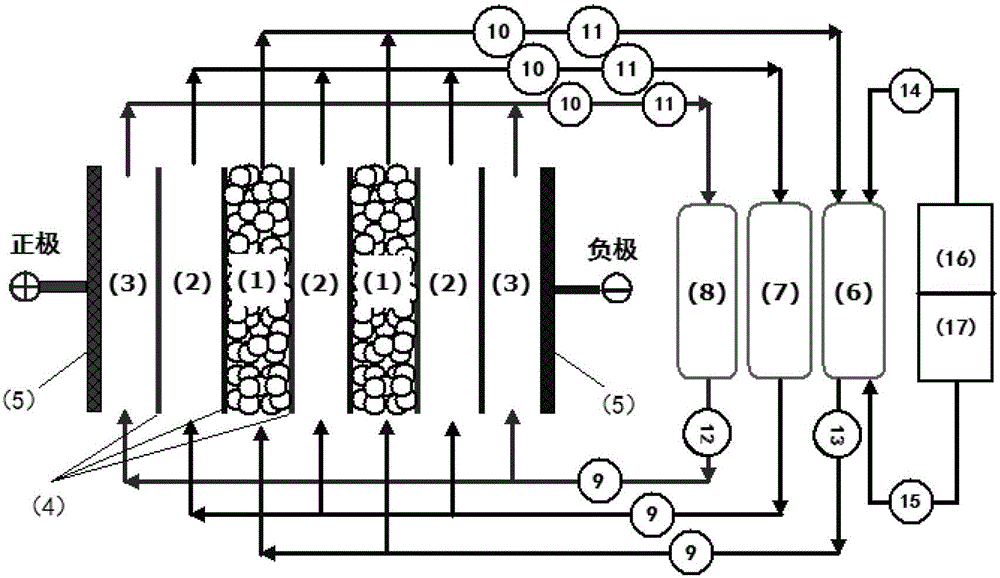

[0073] Example 2 Packed bed electrodialysis is used for the separation of glutamic acid and lactic acid in fermentation waste liquid

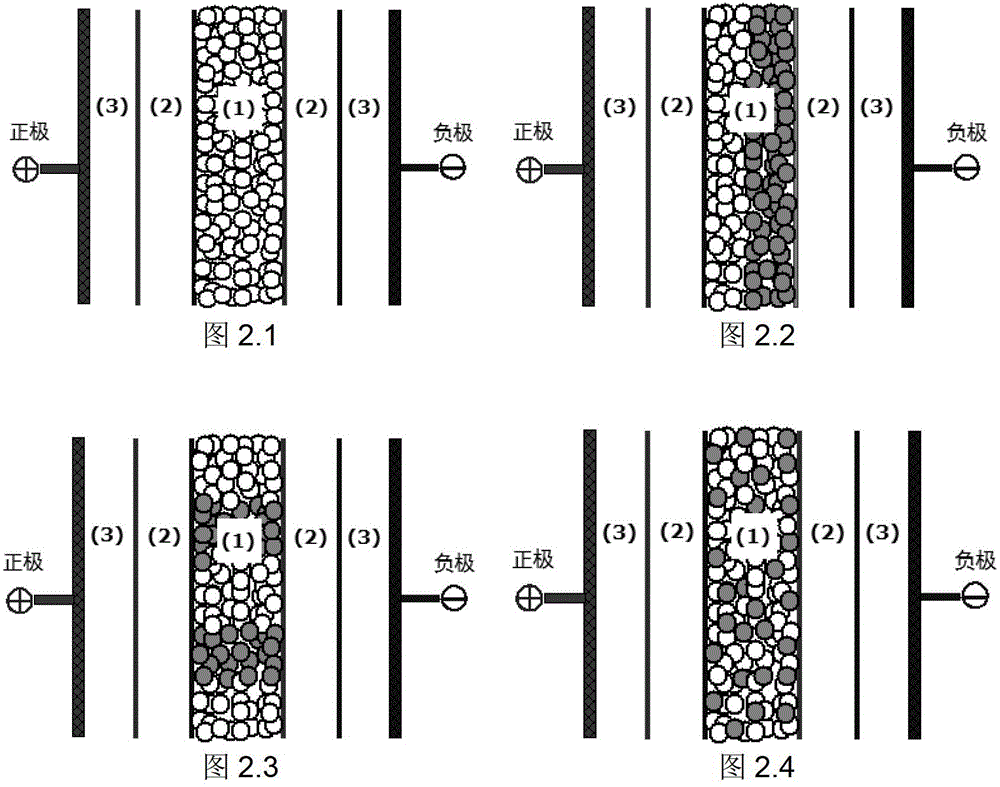

[0074] Compared with conventional electrodialysis, the separator of packed bed electrodialysis dilute room is about 5mm thick, without woven mesh in the middle, and is used to fill different types of ion exchange resins. Other components and operating conditions are the same as conventional electrodialysis. Adopt packed bed electrodialysis device of the present invention, investigate inert resin, ion exchange resin such as 201*7 (strong base type), 001*1.1 (strong acid type), WK10 (weak acid type), WA30 (weak base type) etc. The effect of the separation of glutamic acid and lactic acid in waste liquid, the first two are from the chemical plant of Nankai University, and the latter two are from Mitsubishi, Japan.

[0075] When filling inert resin: Since the inert resin has no ion exchange groups, in this electrodialysis system, the transmembrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com