N-type silicon substrate based back contact type HIT (Heterojunction with Intrinsic Thin layer) solar cell structure and preparation method thereof

A back-contact solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as reducing the efficiency of sunlight utilization, and achieve the effects of avoiding shading, improving efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

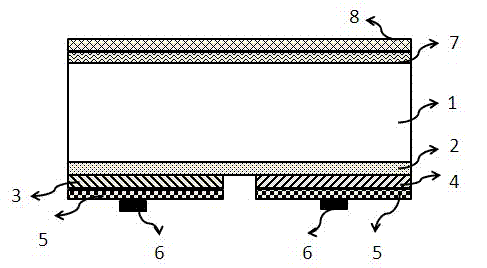

[0032] Refer to the accompanying drawings in the manual figure 1 , N-type silicon substrate 1 light-receiving surface from the inside to the outside is the light-receiving surface n-type amorphous or microcrystalline silicon layer 7, anti-reflection layer 8; the backlight surface is the intrinsic amorphous or microcrystalline silicon layer from the inside to the outside 2. There is an interval between the p-type amorphous or microcrystalline silicon layer 3 and the n-type amorphous or microcrystalline silicon layer 4 on the backlight surface and are alternately arranged on the intrinsic amorphous or microcrystalline silicon layer 2, and the p-type amorphous or microcrystalline silicon layer 2 Both the microcrystalline silicon layer 3 and the n-type amorphous or microcrystalline silicon layer 4 on the backlight surface are covered with a transparent conductive film 5 , and the metal electrode 6 is located on the transparent conductive film 5 .

[0033] p-type amorphous or micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com