Tooth-and-gum-oriented high-efficiency mesh repairing method

A tooth and mesh technology, applied in the field of geometric repair, can solve the problems of inability to meet the needs of tooth rearrangement and orthodontic plan design, roughness, inapplicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The method for repairing the proximal surface of the present invention will be described in detail below in conjunction with the accompanying drawings.

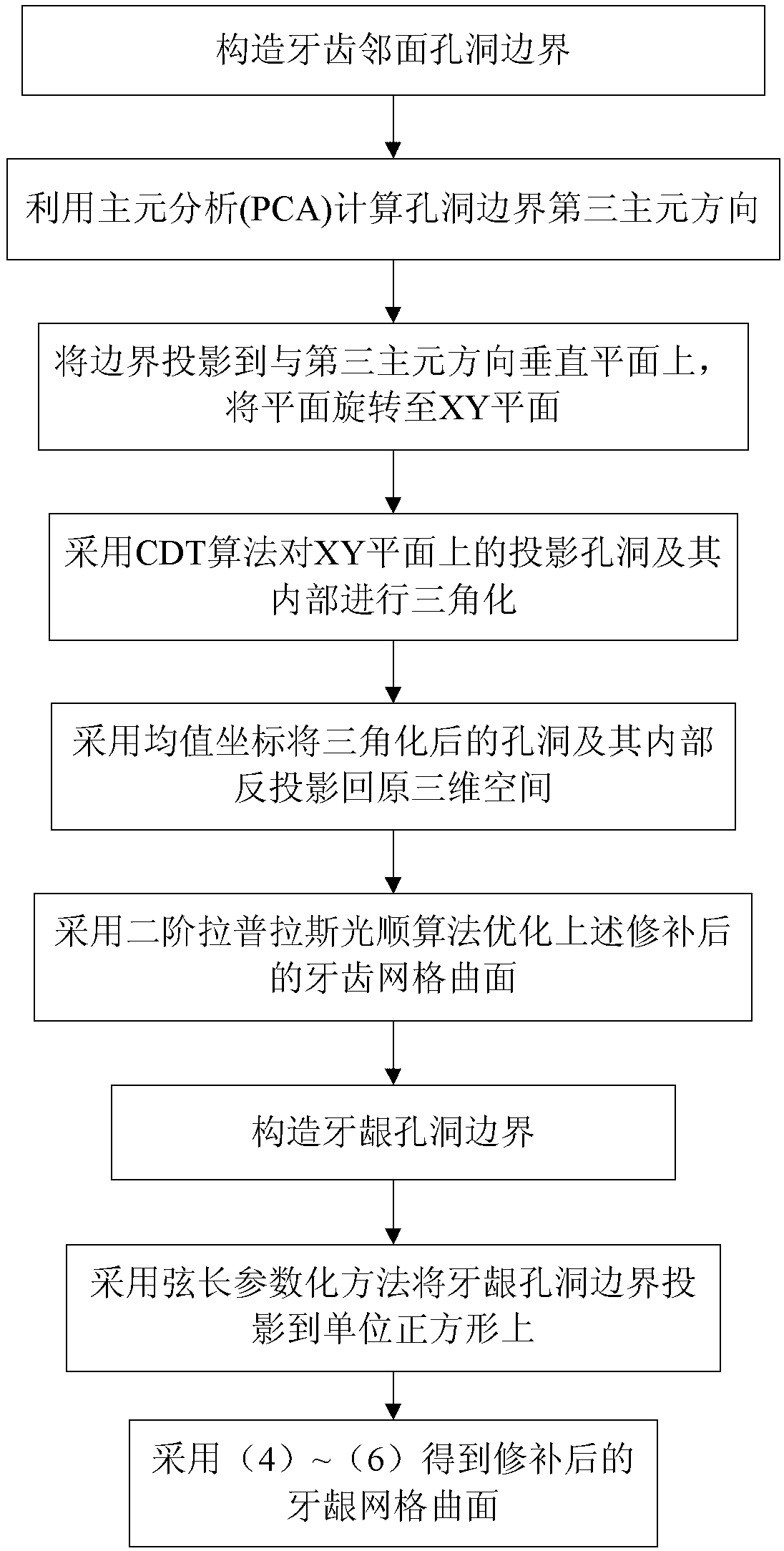

[0076] a kind of like figure 1 The high-efficiency mesh repair method for the teeth and gums shown, including steps:

[0077] (1) Select two points on the boundary of the tooth mesh model as the start and end vertices of the tooth-proximal cavity boundary to construct the tooth-proximal cavity boundary.

[0078] The construction of the interdental cavity boundary further comprises the steps of:

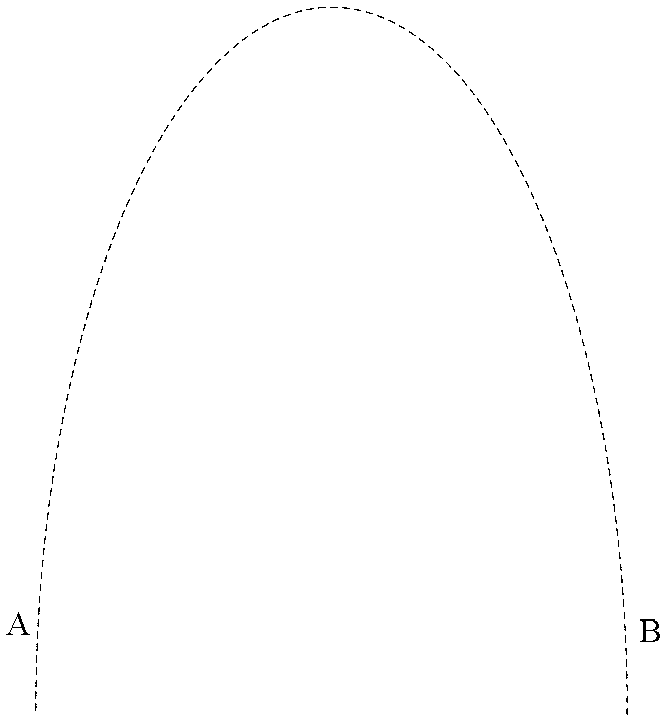

[0079] (1.1) figure 2 It is a schematic diagram of the adjacent surface of the tooth mesh model. The dotted line constitutes part of the boundary of the adjacent surface. Use the mouse to select two points on the boundary of the tooth mesh model as the start and end vertices of the hole boundary of the tooth adjacent surface. figure 2 are point A and point B respectively;

[0080] (1.2) If image 3 As shown, connect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com