Method and special stop-pass caliper gauge for detecting low-taper circular conical surface

A detection method and technology of conical surface, applied in the direction of measuring gauge, gauge, mechanical counter/curvature measurement, etc., can solve the problems of shortening the debugging cycle of new products, mismatching test data, etc., to maintain consistency, facilitate verification and comparison, Easy to detect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

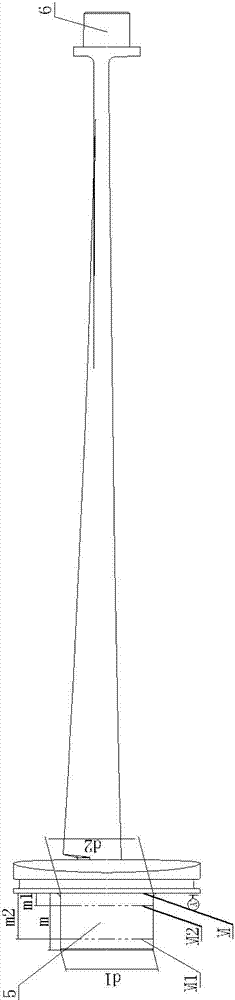

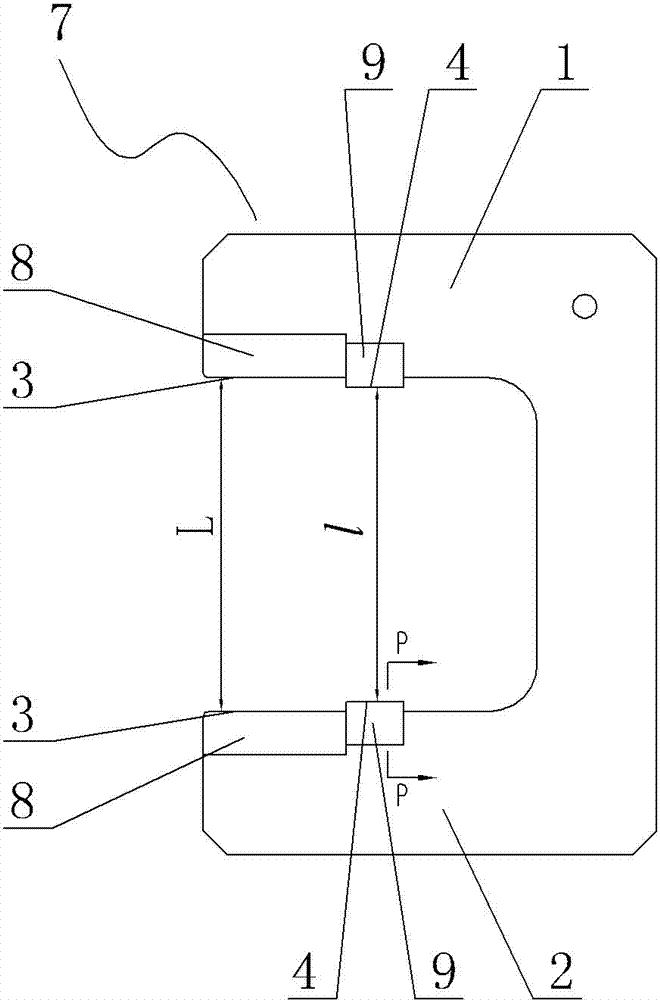

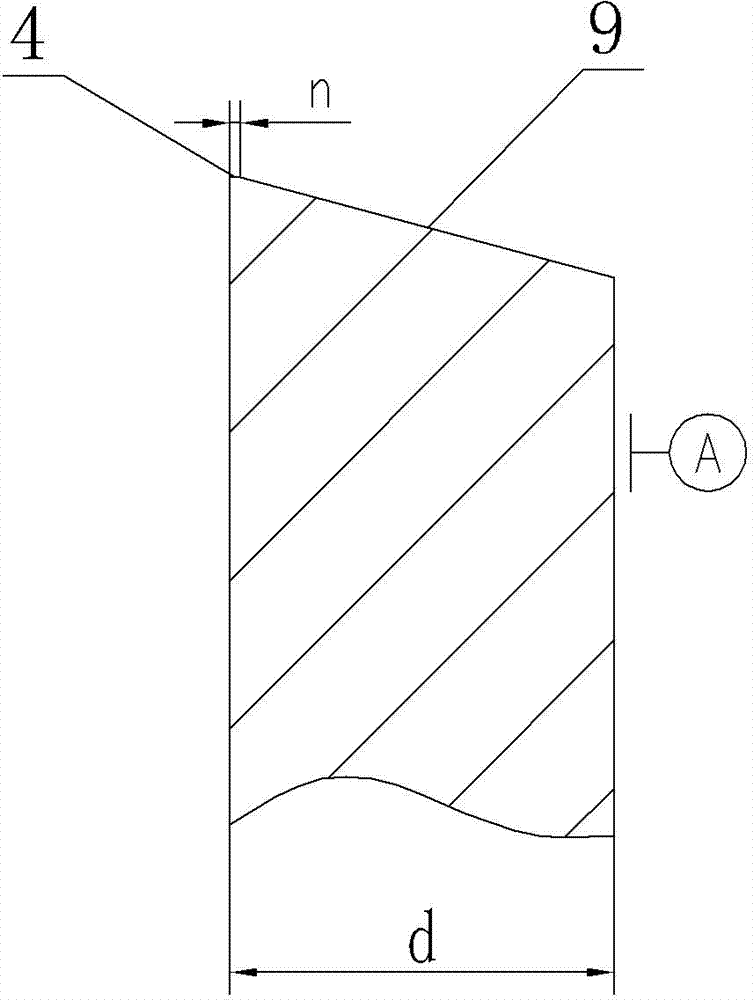

[0017] A detection method for a low-taper conical surface. Two sections with different distances from the Z surface are respectively intercepted on the conical surface of the workpiece to be tested, and the contour circles M1 and M2 of the two sections are used as detection objects. See figure 1 According to the design tolerance requirements of the two cross-sectional contour circles M1 and M2, two special stop-going snap gauges are prefabricated, and the two special stop-going snap gauges are used to detect the corresponding two cross-sectional contour circles on the conical surface of the workpiece to be tested. If If the two cross-sectional profiles can respectively pass through the through ends of two special through-stop calipers and be limited by the stop ends, the conical surface of the workpiece under test meets the design requirements.

[0018] Then use a three-coordinate detector to inspect and detect the conical surface of the measured workpiece. After the three-coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com