Anti-dropping type feeder line clamping device for ship

A technology for feeder clamps and ships, applied in the field of feeder clamps, which can solve the problems of unable to continue clamping, feeder falling off, and use restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

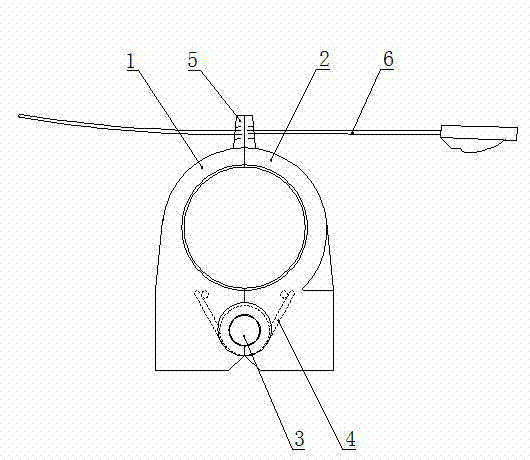

[0008] Such as figure 1 As shown, it includes left-half plastic feeder card 1, right-half plastic feeder card 2, pin shaft 3, torsion spring 4, lug plate 5, and stainless steel cable tie 6.

[0009] The above-mentioned left-half plastic feeder card 1 and right-half plastic feeder card 2 are arranged symmetrically, and arc-shaped feeder card slots are opened on the inner sides of the upper parts of the left-half plastic feeder card 1 and the right half-plastic feeder card 2. The lower parts of the left-half plastic feeder card 1 and the right-half plastic feeder card 2 are connected by a pin shaft 3 on which a torsion spring 4 is sleeved.

[0010] The tops of the left-half plastic feeder card 1 and the right-half plastic feeder card 2 are corresponding to ear plates 5, and the two ear plates 5 are provided with flat through-holes that communicate with each other. with 6.

[0011] When in use, first pull out the stainless steel cable tie 6, break off the left and right half pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com