Central multi-drive transmission device of elongated output shaft of speed reducer

A transmission device and reducer technology, applied in the direction of transmission device, gear transmission device, transmission box, etc., can solve the problems of low transmission efficiency, time-consuming and inconvenient, long production cycle, etc., to reduce additional losses, keep the environment clean, and improve transmission efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

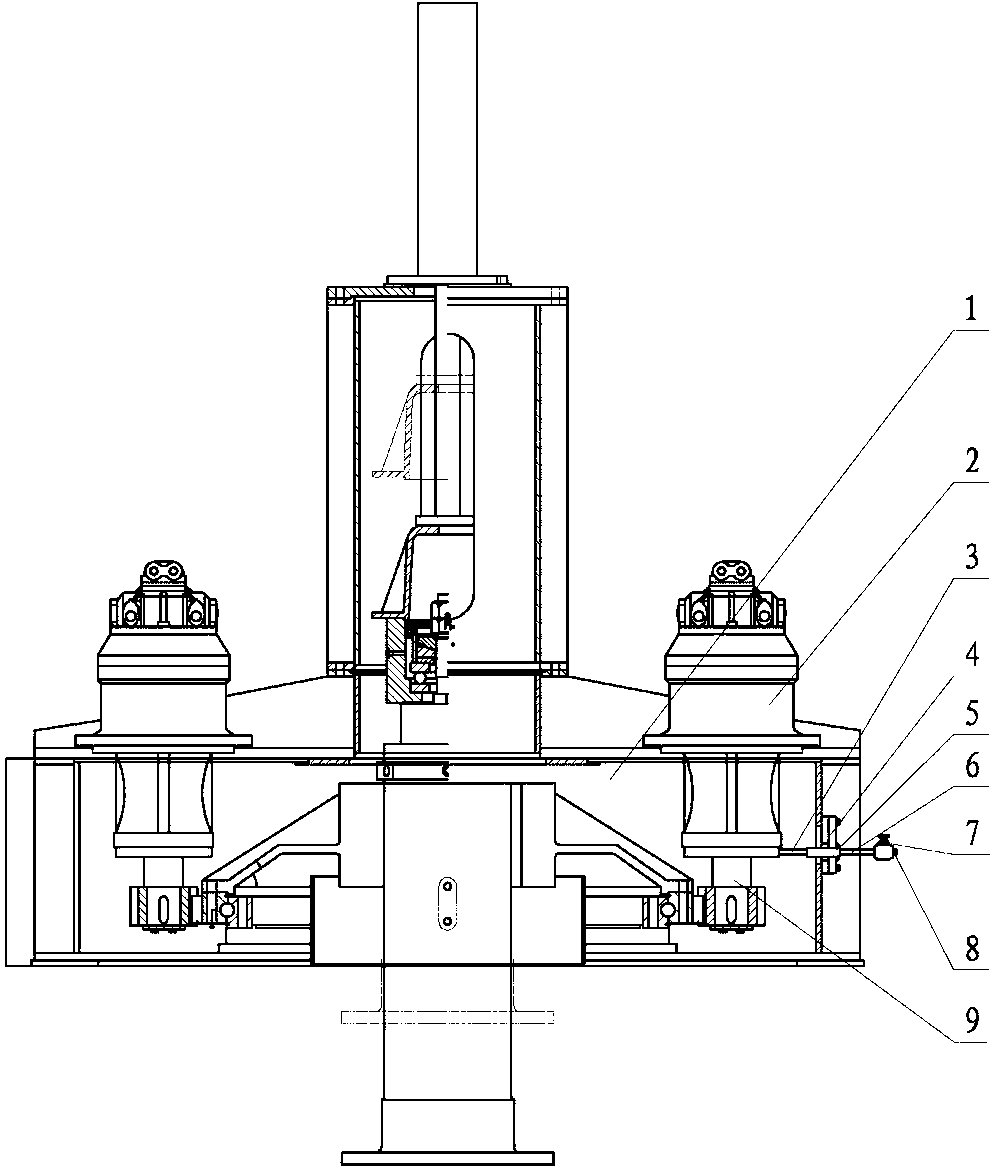

[0021] As shown in the drawings, the present invention includes a transmission box 1, a reducer 2, an oil discharge pipe 3 in the box, a combination hole cover 4, a plate-through pipe joint 5, an oil discharge pipe 6 outside the box, a stop valve 7, an oil plug 8, an extended Output shaft 9 etc.

[0022] The reducer 2 with the extended output shaft 9 is installed on the transmission box 1, and its casing is correspondingly lengthened. The middle part of the casing has a mounting flange, which is installed on the transmission box 1. The parts below the reducer 2 flange are The casing enters the center transmission gearbox; a bearing is installed at the end of the casing to withstand the additional force generated by the lengthening of the shaft, improve the working condition of the reducer 2, and make the force condition of the output shaft 9 of the reducer reasonable ;The pinion gear is assembled at the end of the extended output shaft 9 below the casing, and it meshes with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com