Composite roller wheel with full complement tapered rollers

A technology of composite rollers and tapered rollers, used in lifting devices, bearings, mechanical equipment, etc., can solve the problem that bearings cannot meet the needs of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

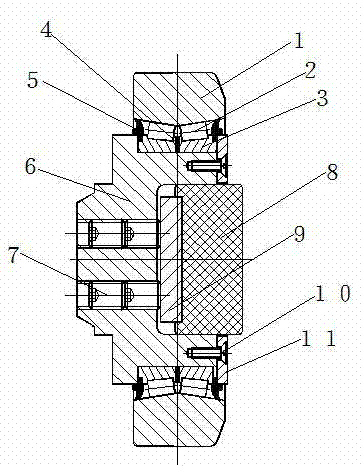

[0010] Depend on figure 1 From the schematic diagram shown, it can be known that the composite roller of the present invention is composed of an outer bearing assembly and an inner slider assembly.

[0011] The outer bearing assembly is composed of an outer ring 1, an inner ring 3, a roller 2, a retaining ring 5 and a spacer 4. There are two inner rings 3 in total, and a spacer 4 is installed between the two inner rings 3. There is a raceway evenly opened on the surface of the ring 3, the rollers 2 are installed in the raceway, the two rows of rollers 2 are inclined in opposite directions, and the direction of inclination is that the rollers 2 gradually penetrate into the inner ring 3 from the outside to the inside, and the outer ring 1 is directly set on the two rows of rollers 2, and there is a retaining ring 5 connected between the outer ring 1 and the inner ring 3. There are two retaining rings 5, which are respectively located on both sides of the two rows of rollers 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com