Method for increasing output of sintering process

A production and process technology, applied in the field of increasing the output of the sintering process, can solve the problems of a large increase in the amount of quicklime, the inability to reduce the amount of quicklime, and the increase of sintering raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

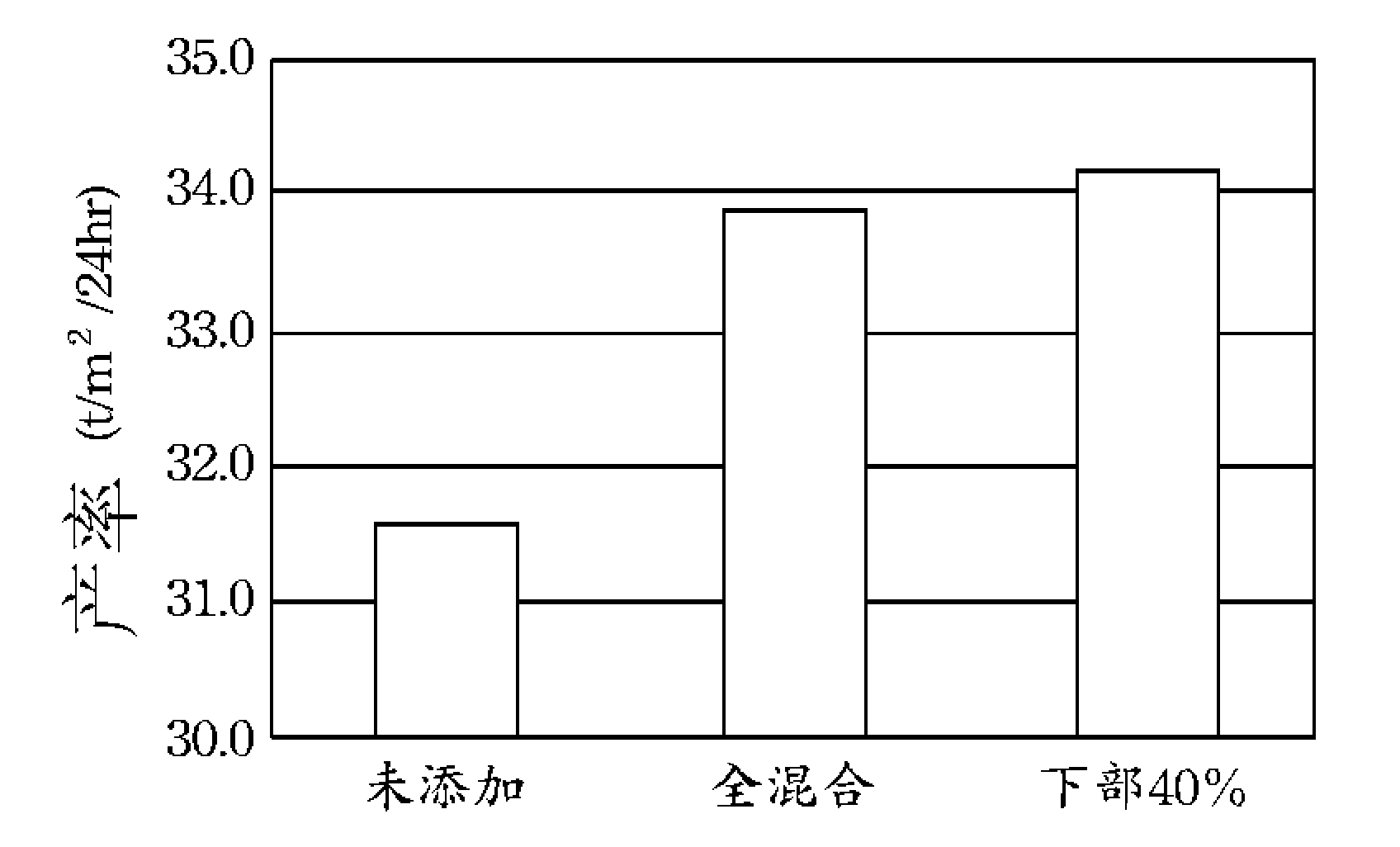

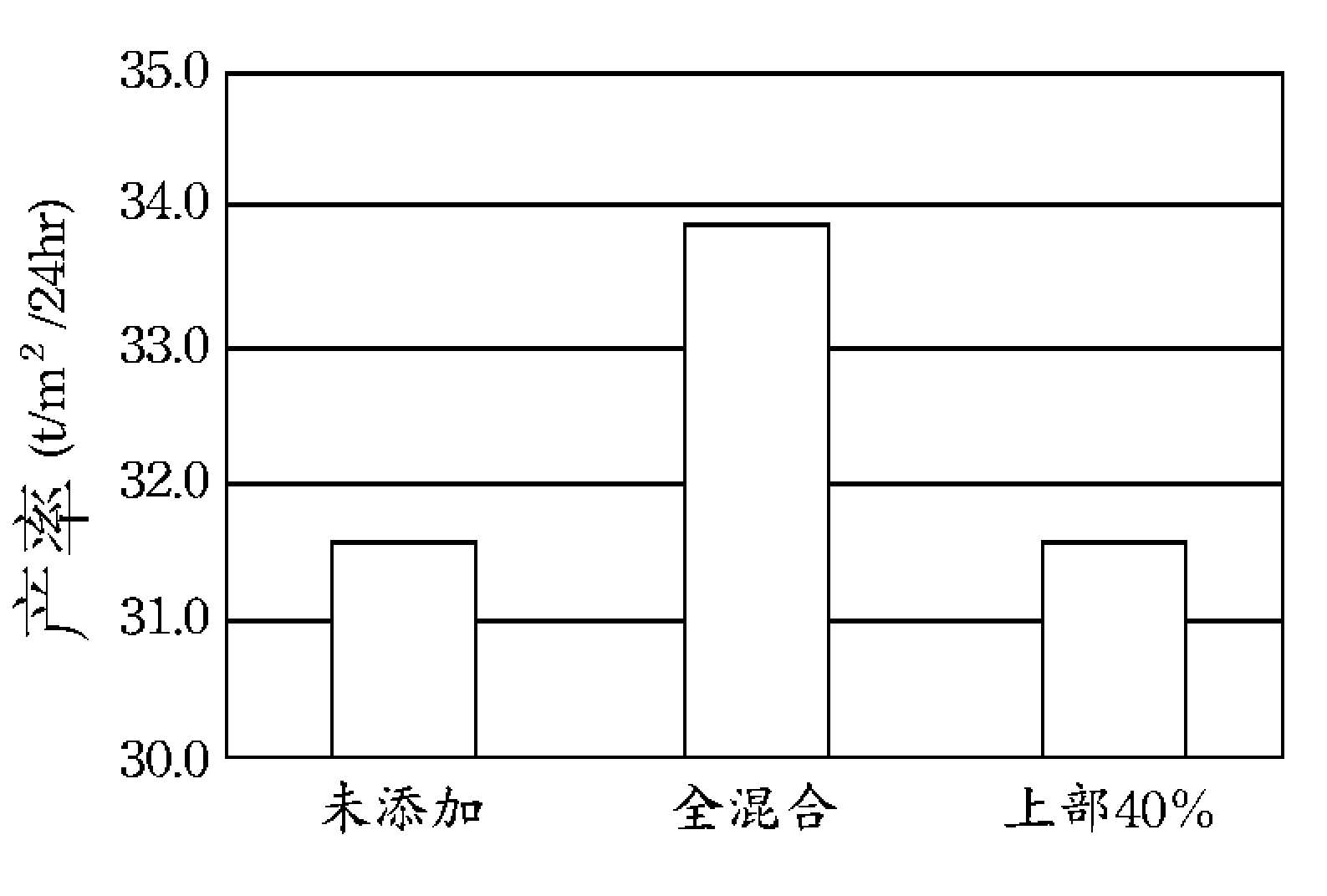

[0021] Please refer to FIG. 1 , which is a histogram depicting the yield of sintered ore obtained by adding no quicklime, adding 1wt% quicklime and completely mixing with the sintering raw material, and adding 1wt% quicklime in the upper 40% of the sintering raw material. Under the same configuration of sintering raw materials, the yields of the sintering raw materials without adding quicklime, adding 1wt% quicklime and completely mixing with the sintering raw materials, and adding 1wt% quicklime in the upper 40% of the sintering raw materials were measured. From Figure 1, the inventor found that under the same configuration of sintering raw materials, adding 1wt% quicklime to all the sintering raw materials, the sintering yield can be better than that of sintering raw materials without adding quicklime. However, if only 1wt% of quicklime is mixed in the upper part of the sintering raw material, that is, 40% of the upper part of the sintering raw material, then under the same r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com