Horizontal high-frequency quenching machine

A high-frequency quenching, horizontal technology, used in quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of high labor intensity of workers, reduce product quality, and be easily deformed by compression, achieve fast response to instructions, and improve the rate of qualified products. , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

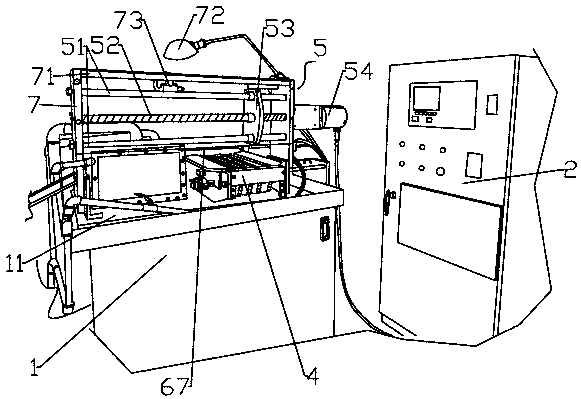

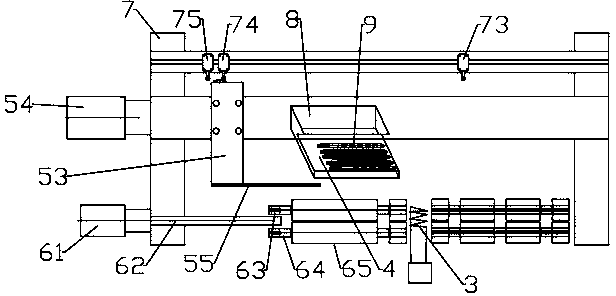

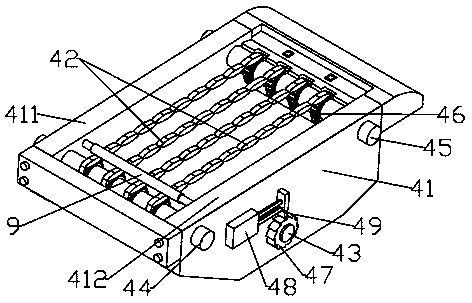

[0036] Such as figure 1 , 2 As shown, a horizontal high-frequency quenching machine of the present invention includes a base 1, a high-frequency quenching heating device, a cooling liquid, and a cooling oil tank that collects the cooling liquid and circulates the cooling liquid. The high-frequency quenching heating device includes a high-frequency power supply The control cabinet 2, the induction coil 3 connected to the high-frequency power supply circuit, wherein the cooling liquid flows through the position of the induction coil, the horizontal high-frequency quenching machine also includes a stepping feeding device 4, a pushing conveying device 5 for workpiece quenching, The workpiece turning device 6 placed horizontally when the workpiece is quenched, the program control system and the corresponding electrical system are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com