Method for preparing nefopam intermediate I

An intermediate and solid technology, applied in the field of medicine and chemical industry, can solve problems such as high toxicity, and achieve the effect of increasing yield and improving post-processing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

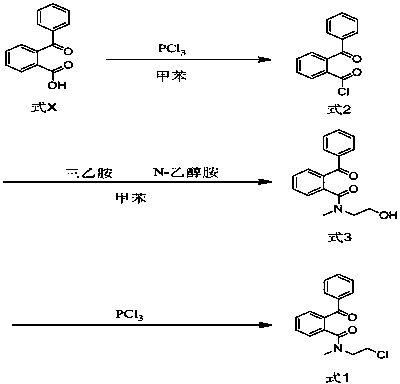

Image

Examples

Embodiment 1

[0037] (1) Put 9L of toluene into the reaction kettle, and put in 3.6kg of o-benzoylbenzoic acid while stirring. Add 0.9kg of phosphorus trichloride dropwise, the dropwise addition is completed in about 1 hour, and stir for 16 hours at 25°C. Stand for stratification, and remove the insoluble matter in the lower layer. The upper layer acid chloride solution is transferred to a drop tank or container.

[0038] (2) Put 1.32kg of N-methylethanolamine, 7.26L of toluene, and 1.98kg of triethylamine into the reaction kettle in sequence, and cool to -5°C~0°C while stirring. Slowly add the above-mentioned acid chloride solution dropwise, and control the dropping temperature at -5°C~5°C, not exceeding 5°C. After the dropwise addition is completed, heat to 25°C±5°C and stir for 1h to prepare the reaction solution.

[0039] (3) Add 1 kg of phosphorus trichloride dropwise to the reactor again, and finish dropping within 1h~2h. Then heated to 75°C±5°C for 4h. Remove the salt in the org...

Embodiment 2

[0042] (1) Put 9L of toluene into the reaction kettle, and put in 3.6kg of o-benzoylbenzoic acid while stirring. Add 0.9kg of phosphorus trichloride dropwise, the dropwise addition is completed in about 1 hour, and stir for 16 hours at 25°C. Stand for stratification, and remove the insoluble matter in the lower layer. The upper layer acid chloride solution is transferred to a drop tank or container.

[0043] (2) Put 1.32kg of N-methylethanolamine, 7.26L of toluene, and 1.98kg of triethylamine into the reaction kettle in sequence, and cool to -5°C~0°C while stirring. Slowly add the above-mentioned acid chloride solution dropwise, and control the dropping temperature at -5°C~5°C, not exceeding 5°C. After the dropwise addition, heat to 25°C±5°C and stir for 1h for later use.

[0044] (3) Add 1 kg of phosphorus trichloride dropwise to the reactor again, and finish dropping within 1h~2h. Heat to 75°C±5°C for 4h. Filter while hot to remove the salt in the organic phase, lower t...

Embodiment example 3

[0047](1) Put 9L of toluene into the reaction kettle, and put in 3.6kg of o-benzoylbenzoic acid while stirring. Add 0.9kg of phosphorus trichloride dropwise, the dropwise addition is completed in about 1 hour, and stir for 16 hours at 25°C. Stand for stratification, and remove the insoluble matter in the lower layer. The upper layer acid chloride solution is transferred to a drop tank or container.

[0048] (2) Put 1.32kg of N-methylethanolamine, 7.26L of toluene, and 1.98kg of triethylamine into the reaction kettle in sequence, and cool to -5°C~0°C while stirring. Slowly add the above-mentioned acid chloride solution dropwise, and control the dropping temperature at -5°C~5°C, not exceeding 5°C. After the dropwise addition, heat to 25°C±5°C and stir for 1h for later use.

[0049] (3) Add 1kg of phosphorus trichloride dropwise to the reactor again, and finish dropping within 1h~2h. Heat to 75°C±5°C for 4h. Remove the salt in the organic phase by filtration while it is hot,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com