Preparation system device and preparation method for high-performance black master-batches

A technology of carbon black masterbatch and preparation system, which is applied in the masterbatch preparation system device and its preparation field, which can solve the problems of carrier resin and carbon black scattering, long production process, poor performance of carbon black masterbatch, etc., and achieve product The effect of good quality stability, high production efficiency and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

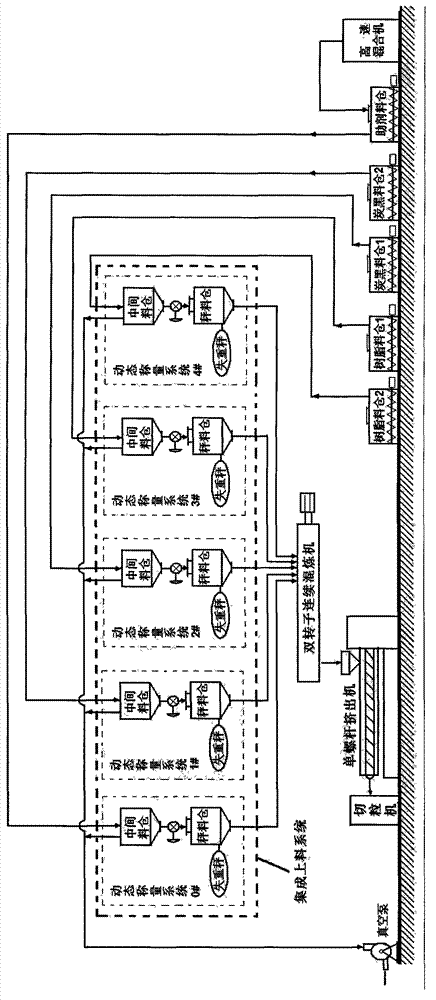

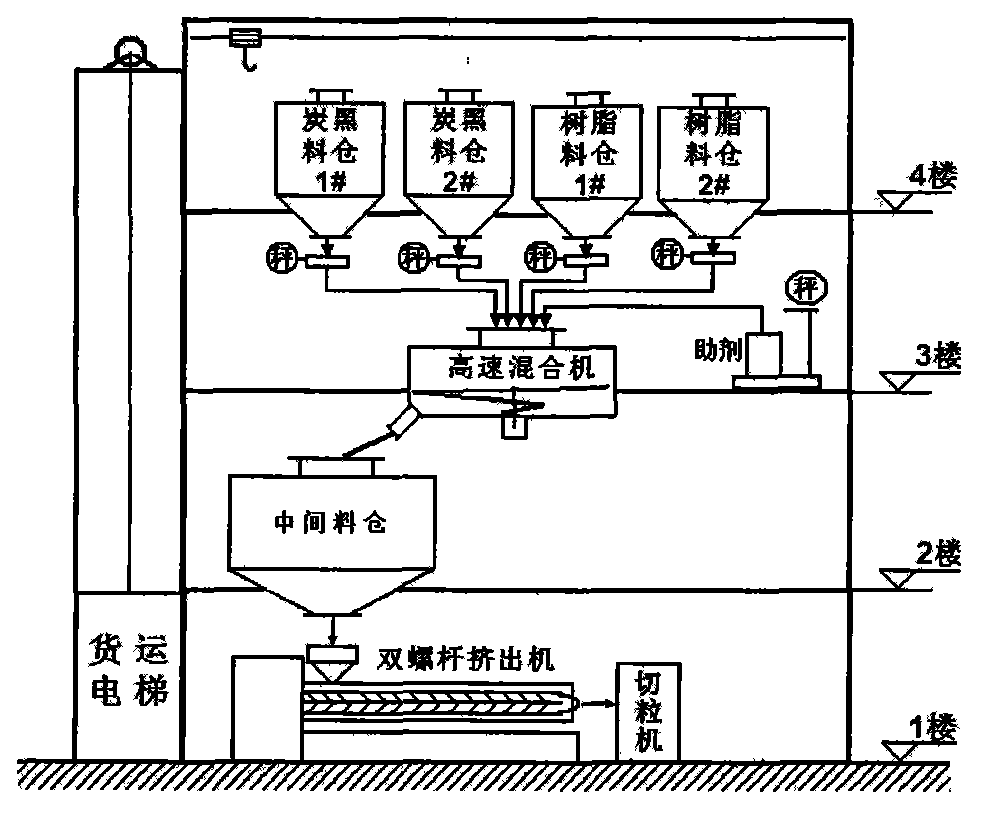

Method used

Image

Examples

Embodiment 1

[0038] Raw material formula: 78.8 parts of HDPE (MFR=5g / 10min under the condition of 190°C×2.16kg), 20 parts of carbon black, 0.2 parts of bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite antioxidant, 2,2'methylene-bis(4-methyl-6-tert-butylphenol) antioxidant 0.3 part, calcium stearate 0.5 part, fluoropolymer processing aid (Dynamar TM PPA) 0.2 parts.

[0039] Preparation:

[0040] Bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite antioxidant, 2,2'methylene-bis(4-methyl-6-tert-butylphenol) antioxidant, hard Calcium acetate, fluoropolymer processing aids (Dynamar TM PPA) and HDPE resin according to the ratio of 0.2:0.3:0.5:0.2:10 in the high-speed mixer at low speed, that is, control the speed of the mixer below 500rpm and stir for 5 minutes, then start high-speed stirring, that is, control the speed of the mixer above 1000rpm for 3 minutes After that, it can be discharged into another jacketed water-cooled mixer, and the mixture will continue to mix in the ...

Embodiment 2

[0044] Raw material formula: 68.3 parts of HDPE (MFR=16g / 10min under the condition of 190°C×2.16kg), 30 parts of carbon black, 0.3 parts of bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite antioxidant, 0.3 part of 4,4'-thiobis(6-tert-butyl-3-methylphenol) antioxidant, 0.5 part of calcium stearate, 0.3 part of zinc stearate, fluoropolymer processing aid (Dynamar TM PPA) 0.3 parts.

[0045] Preparation:

[0046] Bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite antioxidant, 4,4'-thiobis(6-tert-butyl-3-methylphenol) antioxidant, stearyl Calcium Acid, Zinc Stearate, Fluoropolymer Processing Aids (Dynamar TM PPA) and HDPE resin according to the ratio of 0.3:0.3:0.5:0.3:0.3:10 in the high-speed mixer under low-speed conditions, that is, control the speed of the mixer below 500rpm and stir for 6 minutes, and then start high-speed stirring to control the speed of the mixer at 1000rpm After the above 4 minutes, the material can be discharged to another mixer with ja...

Embodiment 3

[0050] Raw material formula: 58.9 parts of HDPE (MFR=18g / 10min under the condition of 190°C×2.16kg), 40 parts of carbon black, 0.3 parts of tris(2,4-di-tert-butylphenyl) phosphite antioxidant, 2, 2 methylene-bis(4-methyl-6-tert-butylphenol) antioxidant 0.2 part, calcium stearate 0.4 part, fluoropolymer processing aid (Dynamar TM PPA) 0.2 parts.

[0051] Preparation:

[0052] Tris(2,4-di-tert-butylphenyl)phosphite antioxidant, 2,2'methylene-bis(4-methyl-6-tert-butylphenol) antioxidant, stearic acid Calcium, fluoropolymer processing aids (Dynamar TM PPA) and HDPE resin according to the ratio of 0.3:0.2:0.4:0.2:5.5 in the high-speed mixer under low speed conditions, that is, control the speed of the mixer below 500rpm and stir for 3 minutes, then start high-speed stirring, that is, control the speed of the mixer above 1000rpm for 3 minutes After that, the material can be discharged into another jacketed water-cooled mixer, and the mixture is continuously mixed in the jacket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com