Special machine tool for machining hub bearing shells

A technology of hub bearings and special machine tools, which is applied in the direction of metal processing machinery parts, metal processing equipment, supports, etc., can solve the problems of wasting manpower, material and financial resources, low production efficiency, and long processing time, so as to improve work efficiency and save The effect of transit time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

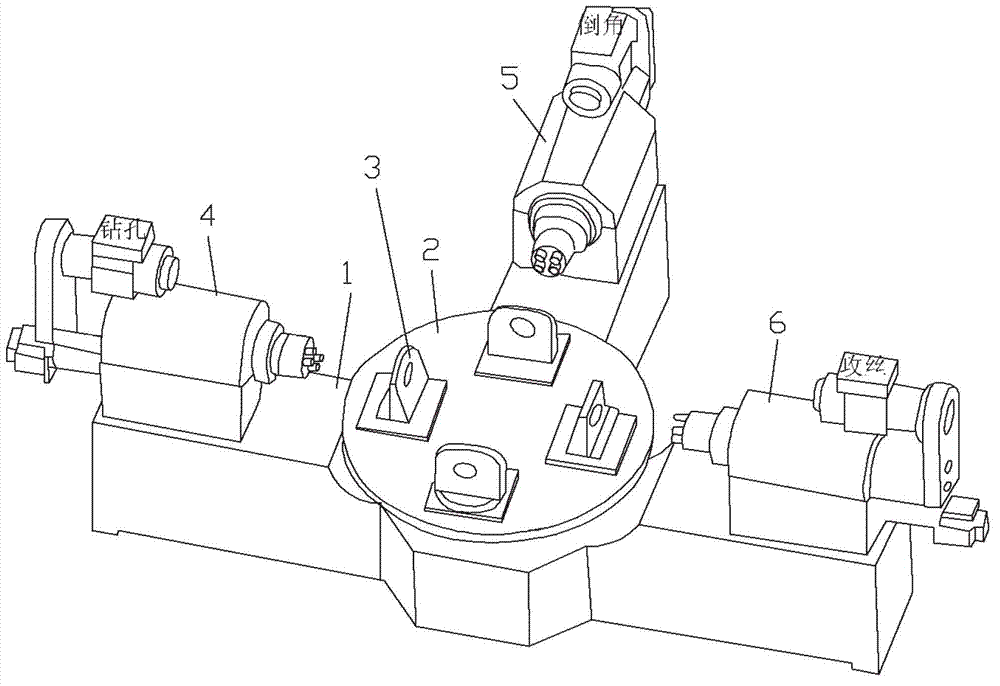

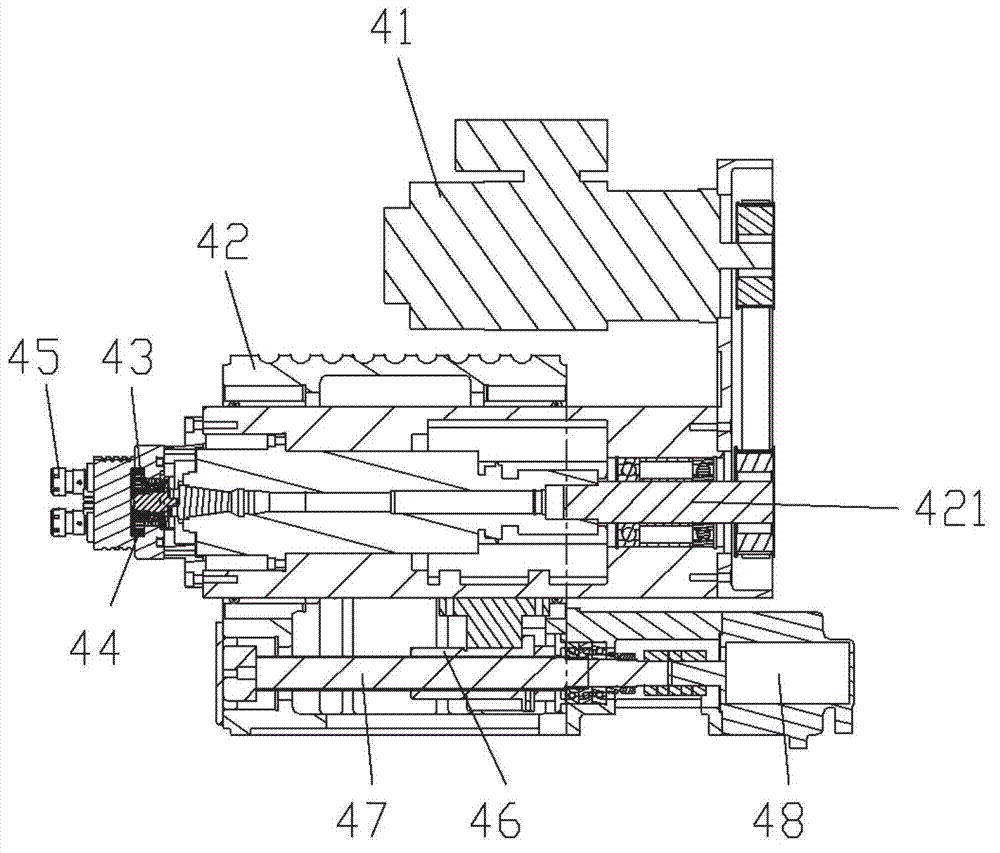

[0020] Example: see Figures 1 to 5 As shown, the special machine tool for wheel hub bearing shell processing includes a frame 1 and a turntable 2. A turntable 2 is installed on the frame 1, and four workpiece fixtures 3 are distributed in a circular array on the turntable 2. The structure of each workpiece fixture 3 is , the workpiece seat 31 is fixed on the turntable 2, the lower part of the workpiece seat 31 is fixed with a hydraulic motor 32, the rotating shaft of the hydraulic motor 32 is fixed with a small turntable 33, the small turntable 33 is fixed on a bearing 34, and the bearing 34 is fixed on the workpiece seat 31 Oil cylinder 35 is fixed on the small turntable 33, and the two ends of the piston rod of oil cylinder 35 are hinged with connecting rod 36 respectively, and the other end of connecting rod 36 is hinged on the workpiece clamping rod 37, and the workpiece clamping rod 37 is inserted in the workpiece clamping seat 38, The middle part of the workpiece holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com