Preparation for silver phosphate nano ball-graphene composite material and photocatalysis application

A composite material and graphene technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of improving stability, avoiding agglomeration, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 0.04g of bovine serum albumin in 100mL of distilled water at room temperature, gradually drop into 10mL of 0.1M silver nitrate solution, after a white colloidal solution is formed, then drop into 100mL of graphene oxide solution (0.5mg / mL); magnetically stir for 2 hours Finally, 3.3 mL of 0.1 M disodium hydrogen phosphate solution was added dropwise, and after magnetic stirring for 4 hours, centrifuged, washed with distilled water, and dried to obtain a silver phosphate nanosphere-graphene composite material.

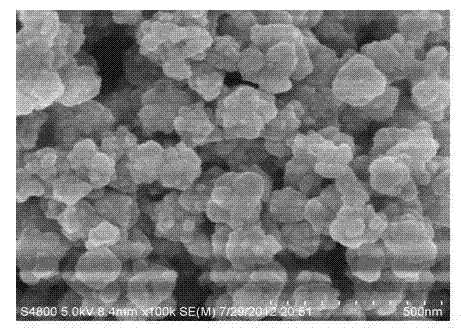

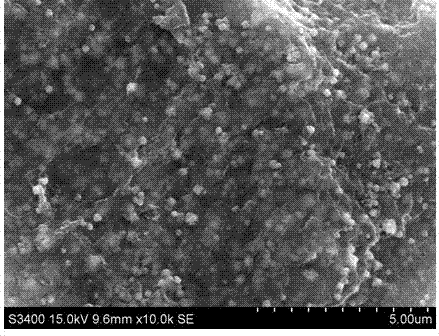

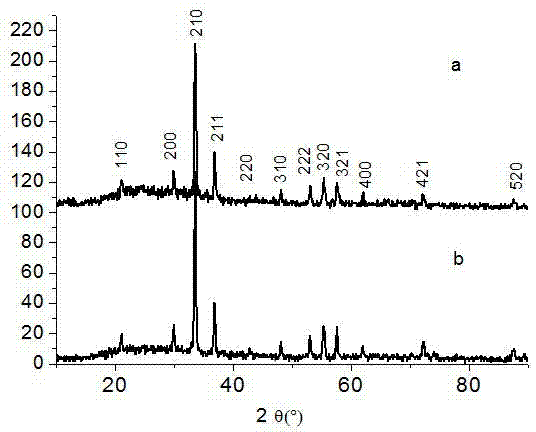

[0031] The scanning microscope picture of the product silver phosphate nanosphere-graphene composite is shown in figure 2 , X-ray diffraction pattern see image 3 In b, the UV-Vis absorption spectrum of the silver phosphate nanosphere-graphene composite is shown in Figure 4 .

[0032] Will 0.025 Disperse one gram of silver phosphate nanosphere-graphene composite into 50 mL of rhodamine B solution with a concentration of 52 ppm, stir magnetically for...

Embodiment 2

[0035] Dissolve 0.04g of bovine serum albumin in 100mL of distilled water at room temperature, gradually drop into 10mL of 0.1M silver nitrate solution, after a white colloidal solution is formed, then drop into 150mL of graphene oxide solution (0.5mg / mL); magnetically stir for 2 hours Finally, 3.3 mL of 0.1 M disodium hydrogen phosphate solution was added dropwise, and after magnetic stirring for 4 hours, centrifuged, washed with distilled water, and dried to obtain a silver phosphate nanosphere-graphene composite material.

[0036] Scanning microscope pictures of the products are shown in figure 2 , X-ray diffraction pattern see image 3 Middle b, UV-Vis absorption spectrum see Figure 4 . Degradation Rhodamine B solution experiment is the same as embodiment 1, the results are shown in Figure 5 , Figure 6 .

Embodiment 3

[0038] Dissolve 0.04g of bovine serum albumin in 100mL of distilled water at room temperature, gradually drop into 10mL of 0.1M silver nitrate solution, after a white colloidal solution is formed, then drop into 200mL of graphene oxide solution (0.5mg / mL); magnetically stir for 2 hours Finally, 3.3 mL of 0.1 M disodium hydrogen phosphate solution was added dropwise, and after magnetic stirring for 4 hours, centrifuged, washed with distilled water, and dried to obtain a silver phosphate nanosphere-graphene composite material.

[0039] Scanning microscope pictures of the products are shown in figure 2 , X-ray diffraction pattern see image 3 Middle b, UV-Vis absorption spectrum see Figure 4 . Degradation Rhodamine B solution experiment is the same as embodiment 1, the results are shown in Figure 5 , Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com