Method and apparatus for determining acceptance/rejection of fine diameter wire bonding

一种引线接合、判定方法的技术,应用在焊接设备、焊接设备、用电元件组装印刷电路等方向,能够解决难以进行评价、成本低、缺乏品质稳定性等问题,达到接合评价及可靠性提高、简单结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

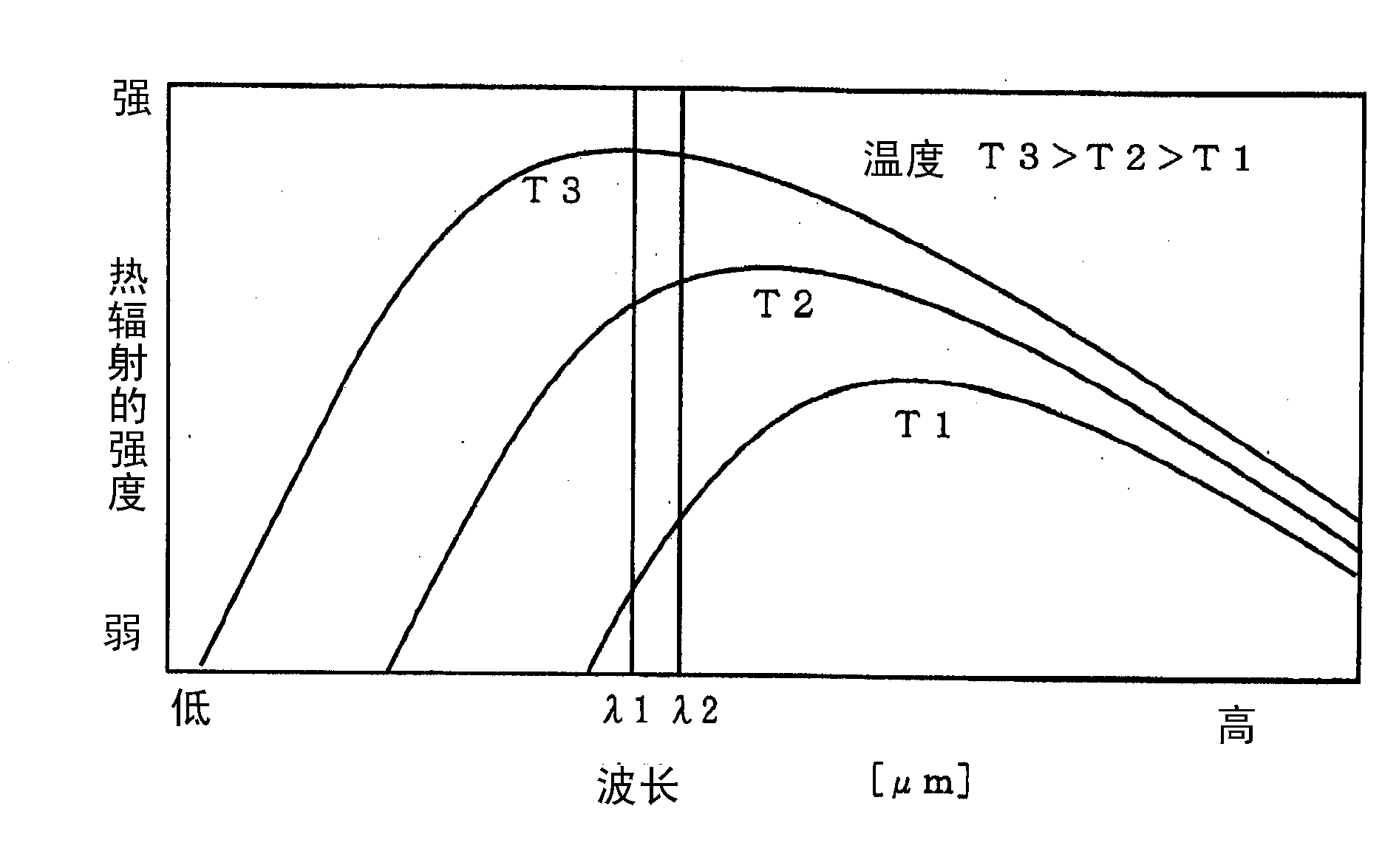

[0032] The pass / fail judgment method of the micro-diameter wire bonding of the present invention is a method of judging its pass or fail based on the bonding area of the bonding portion of the micro-diameter wire, including: a heating process, heating the micro-diameter wire with a laser with a small spot diameter The junction part; the temperature measurement process, correcting the emissivity and high-speed temperature measurement based on a small amount of infrared radiation radiated from the heated part of the junction part of the above-mentioned micro-diameter lead wire; Correction of the absorption rate; and the pass / fail judgment process, based on the measurement temperature corrected in the above-mentioned correction process, the numerical value related to the temperature change after the correction or the bonding area obtained from the temperature change and the correction result The temperature variation under the standard heating power is compared with the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com