AC-LED fluorescent lamp

A technology of AC-LED and fluorescent lamps, applied in the field of lighting, can solve the problems of AC-LED stroboscopic phenomenon, withstand voltage problem, stroboscopic and other problems, and achieve the effects of avoiding stroboscopic phenomenon, reducing costs and high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0042] The invention provides an AC-LED fluorescent lamp, which uses a power drive circuit to convert high voltage into pulsating DC high voltage, and then connects in series an AC-LED array composed of low-voltage and low-power LED chips that meet the requirements of voltage impedance matching and optical parameters, which can make AC High voltage is directly applied to low-voltage low-power LED chips for mainstream applications in the market. The AC-LED fluorescent lamp includes a power drive circuit, an AC-LED array and a kit, which will be introduced separately below.

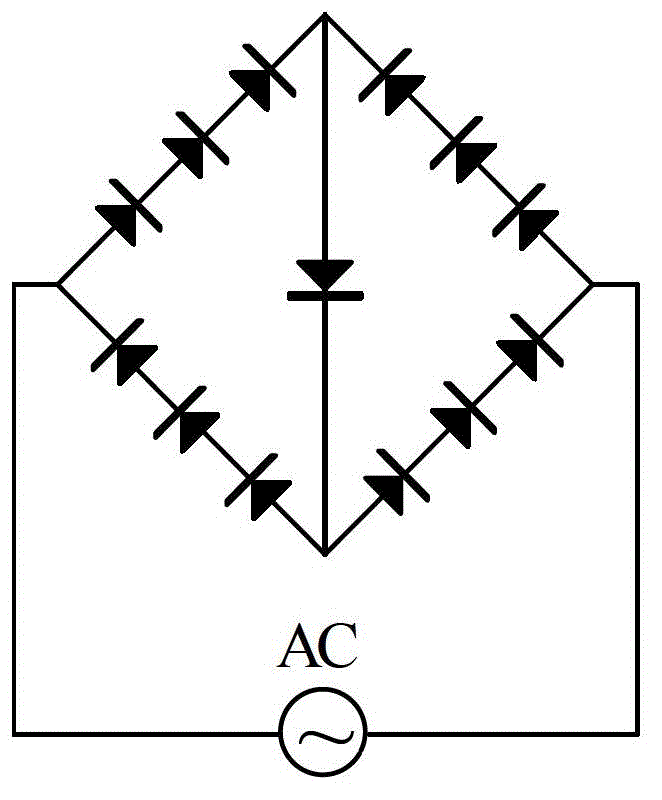

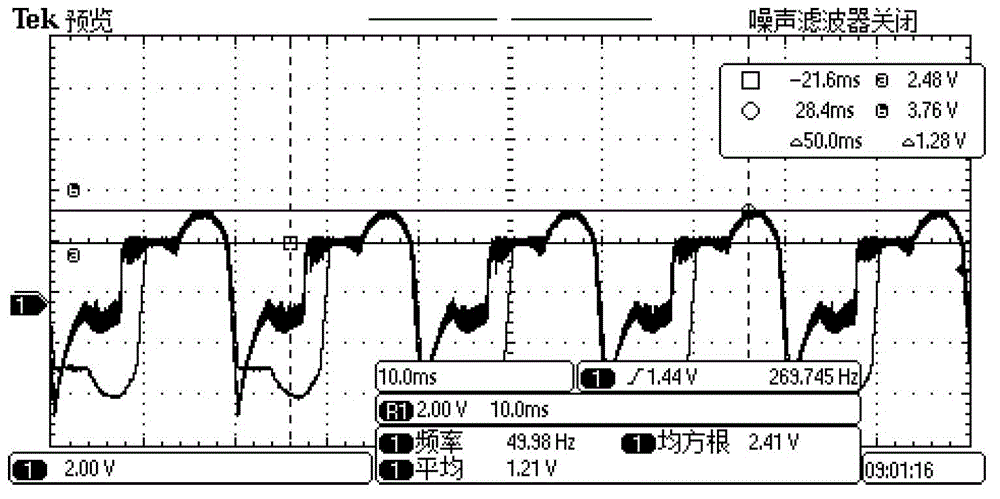

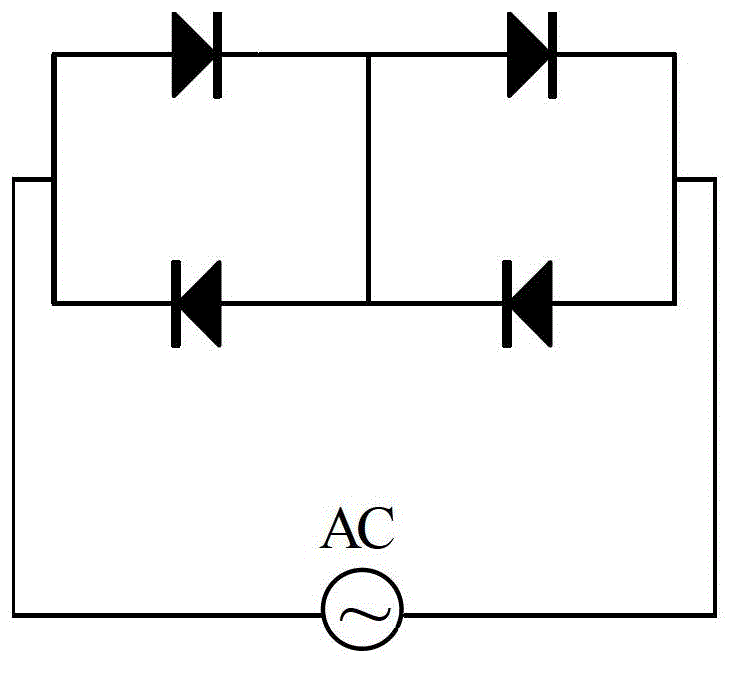

[0043] It has been analyzed above that the figure 1 and image 3 The AC-LED integrated array shown has stroboscopic phenomenon, because the conduction time of the LED in a power cycle is only one-third of the power cycle, and the short conduction time causes visual str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com