Method for analyzing hydrogen sulfide in coke oven gas

An analysis method, hydrogen sulfide technology, applied in the field of analysis, can solve the problems of cumbersome analysis process, large system error, and large measurement error, and achieve the effects of improving detection efficiency, small system error, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

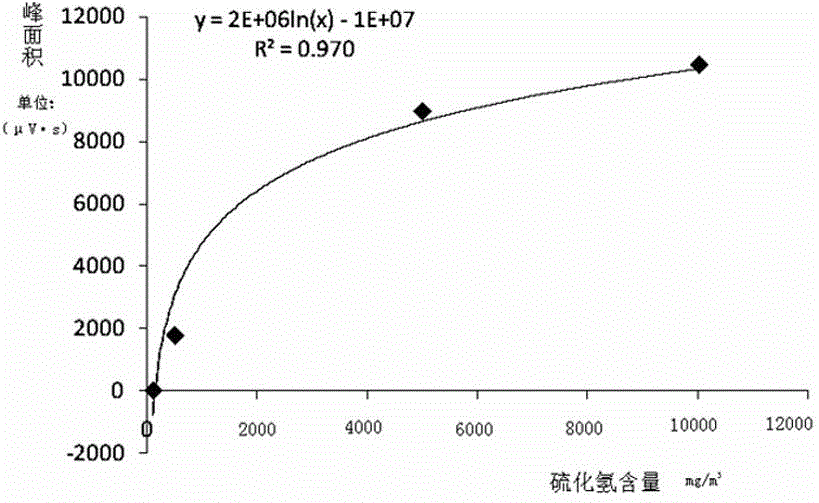

Image

Examples

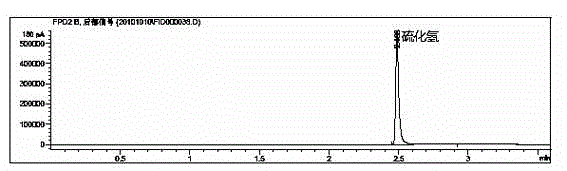

Embodiment 1

[0035] A kind of analysis method of hydrogen sulfide in coke oven gas, its step:

[0036] 1) Establish analysis conditions:

[0037] Equipment: a gas chromatograph with a flame photometric detector, in which the chromatographic column is a GC-Gaspro chromatographic column with a specification of 30.00m × 0.3 2mm; a chromatographic workstation;

[0038] The vaporization temperature at the inlet of the gas chromatograph with a flame photometric detector is set at 150-160°C;

[0039] The detection temperature of the detector on the gas chromatograph with flame photometric detector is set to: 200~210°C;

[0040] Carrier gas N 2 The column flow rate is set to: 2.0 mL / min; the hydrogen flow rate is set to: 75 mL / min;

[0041] The air flow rate is set to: 95 mL / min;

[0042] The amount of sample gas entering the chromatographic column is 1 / 50 of the total flow of sample gas;

[0043] N supplemented at the end of the column 2 The flow rate is set to: 40 mL / min;

[0044] The amo...

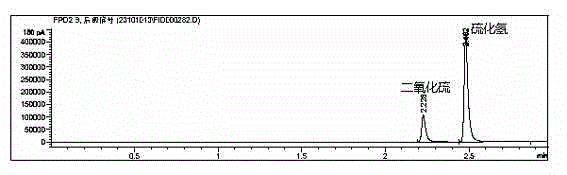

Embodiment 2

[0054] A kind of analysis method of hydrogen sulfide in coke oven gas, its step:

[0055] 1) Establish analysis conditions:

[0056] Equipment: gas chromatograph with flame photometric detector, in which the type of chromatographic column is GC-Gaspro chromatographic column, the specification is 30.00m × 0.3 2mm; chromatographic workstation;

[0057] The vaporization temperature at the inlet of the gas chromatograph is set at 160-170°C;

[0058] The detection temperature of the detector on the gas chromatograph is set at 220-230°C;

[0059] Carrier gas N 2 The column flow rate is set to: 2.4mL / min; the hydrogen flow rate is set to: 70 mL / min;

[0060] The air flow rate is set to: 90 mL / min;

[0061] The amount of sample gas entering the chromatographic column is 1 / 60 of the total flow of sample gas;

[0062] N supplemented at the end of the column 2 The flow rate is set to: 50 mL / min;

[0063] The amount of sample gas to be tested entering the chromatographic column is se...

Embodiment 3

[0073] A kind of analysis method of hydrogen sulfide in coke oven gas, its step:

[0074] 1) Establish analysis conditions:

[0075] Equipment: gas chromatograph with flame photometric detector, in which the type of chromatographic column is GC-Gaspro chromatographic column, the specification is 30.00m × 0.3 2mm; chromatographic workstation;

[0076] The vaporization temperature at the inlet of the gas chromatograph is set at 180-190°C;

[0077] The detection temperature of the detector on the gas chromatograph is set at 230-240°C;

[0078] Carrier gas N 2 The column flow rate is set to: 3.0 mL / min; the hydrogen flow rate is set to: 80 mL / min;

[0079] The air flow rate is set to: 95 mL / min;

[0080] The amount of sample gas entering the chromatographic column is 1 / 55 of the total flow of sample gas;

[0081] N supplemented at the end of the column 2 The flow rate is set to: 55 mL / min;

[0082] The amount of the sample gas to be tested entering the chromatographic colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com