Method for drilling and milling sliding sleeves and ball seats of horizontal well by continuous oil pipe

A horizontal well, drilling and milling technology, applied in the field of oil and gas well workover, can solve the problems that the drilling and milling process is not suitable for drilling and milling operations, the fracturing initiation position is not clear, the drilling and milling pipe string cannot be pulled out, etc. Milling construction efficiency, good drilling and milling performance, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

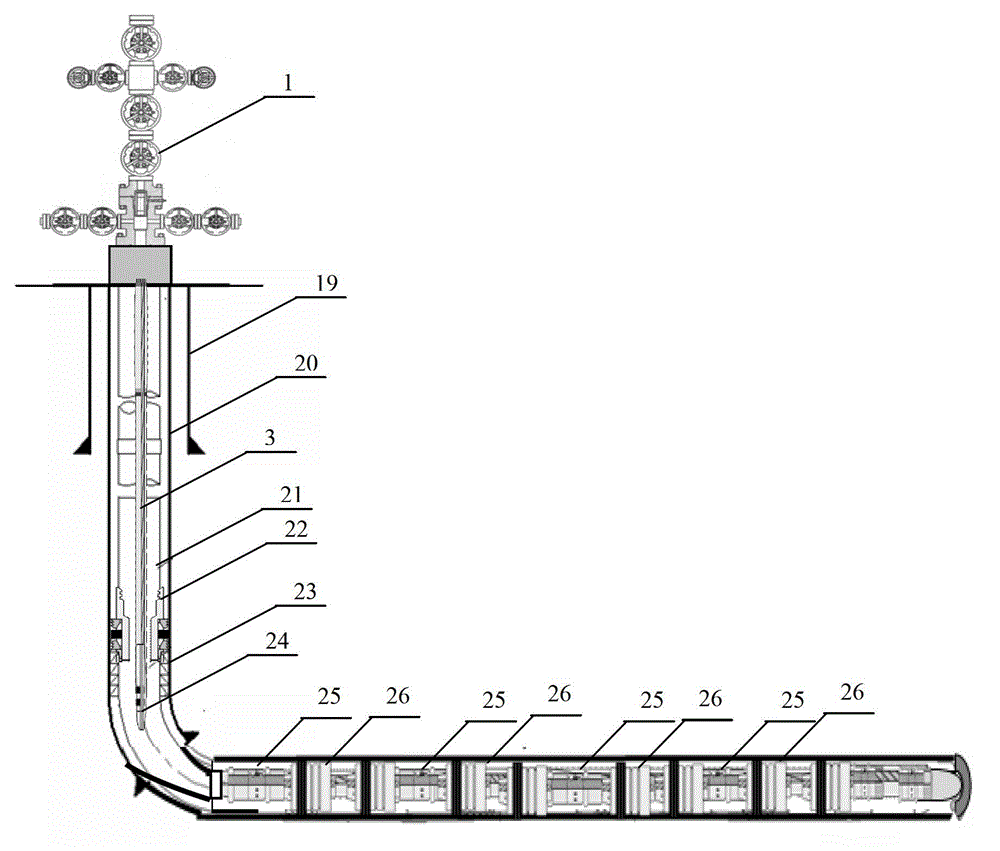

[0033] The method for coiled tubing drilling and milling horizontal well sliding sleeve and ball seat of the present invention comprises the following steps:

[0034] 1) Wellbore preparation: disassemble the wellhead of the original horizontal well, pull out the production string of the original well, run in a combination of 114.3mm casing and back-insert sealing string, adjust the length of the wellhead casing nipple, and back-insert the seal into the liner hanger, annulus Pressure test 5MPa qualified;

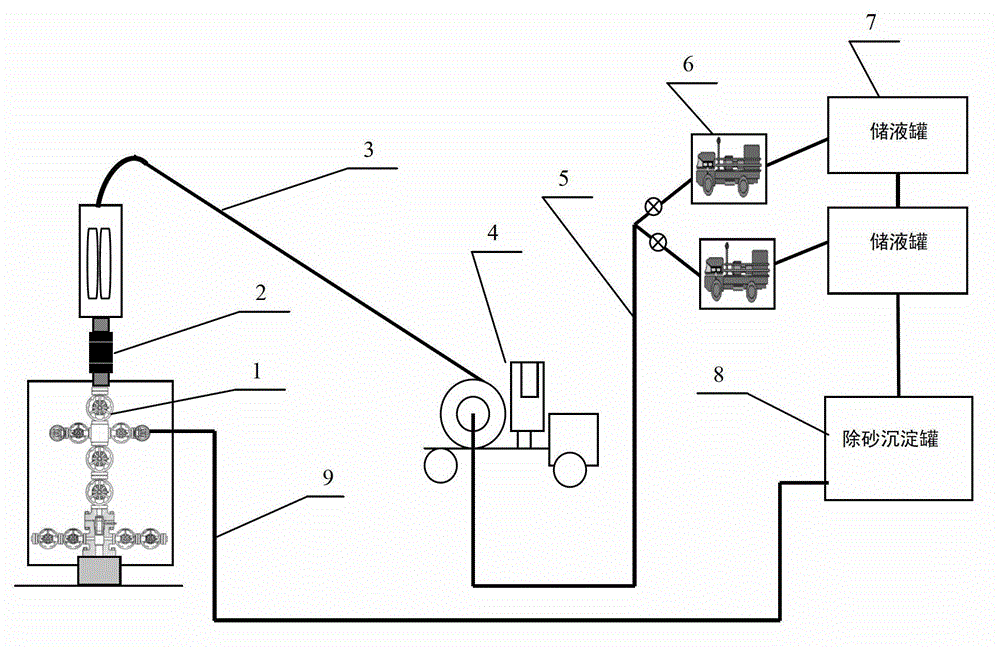

[0035] 2) Surface equipment installation and pipeline connection: Install coiled tubing with an outer diameter of 44.45mm, workover wellhead and blowout preventer, and connect pipelines between fracturing vehicles, coiled tubing, wellhead, sand removal sedimentation tank and liquid storage tank, Among them, the pressure test of the pipeline between the fracturing vehicle and the coiled tubing is 50MPa qualified;

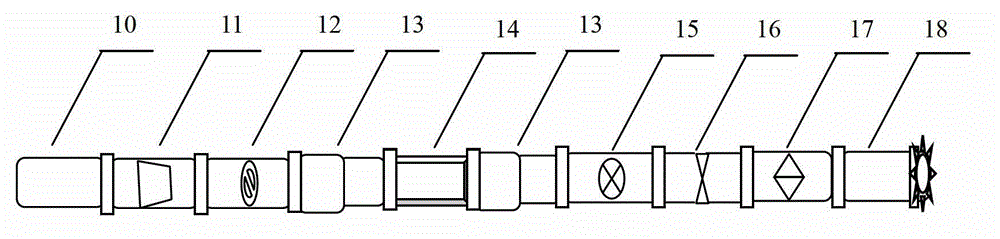

[0036] 3) The ground is connected to the coiled tubing and th...

Embodiment 2

[0047] The method for coiled tubing drilling and milling horizontal well sliding sleeve and ball seat of the present invention comprises the following steps:

[0048] 1) Wellbore preparation: disassemble the wellhead of the original horizontal well, pull out the production string of the original well, run in a combination of 114.3mm casing and back-insert sealing string, adjust the length of the wellhead casing nipple, and back-insert the seal into the liner hanger, annulus Pressure test 5MPa qualified;

[0049] 2) Surface equipment installation and pipeline connection: Install coiled tubing with an outer diameter of 44.45mm, workover wellhead and blowout preventer, and connect pipelines between fracturing vehicles, coiled tubing, wellhead, sand removal sedimentation tank and liquid storage tank, Among them, the pressure test of the pipeline between the fracturing vehicle and the coiled tubing is 50MPa qualified;

[0050] 3) The ground is connected to the coiled tubing and th...

Embodiment 3

[0058] The method for coiled tubing drilling and milling horizontal well sliding sleeve and ball seat of the present invention comprises the following steps:

[0059] 1) Wellbore preparation: disassemble the wellhead of the original horizontal well, pull out the production string of the original well, run in a combination of 114.3mm casing and back-insert sealing string, adjust the length of the wellhead casing nipple, and back-insert the seal into the liner hanger, annulus Pressure test 5MPa qualified;

[0060] 2) Surface equipment installation and pipeline connection: Install coiled tubing with an outer diameter of 44.45mm, workover wellhead and blowout preventer, and connect pipelines between fracturing vehicles, coiled tubing, wellhead, sand removal sedimentation tank and liquid storage tank, Among them, the pressure test of the pipeline between the fracturing vehicle and the coiled tubing is 50MPa qualified;

[0061] 3) The ground is connected to the coiled tubing and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com