Side transmission case for personnel airlock

A technology for personnel gates and transmission boxes, which is applied to manual mechanisms, door/window accessories, engine components, etc., can solve the problems of many operation steps, manpower and time, and investment of a lot of manpower and time, so as to achieve convenient loading and unloading and reduce operations. Torque, to achieve the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

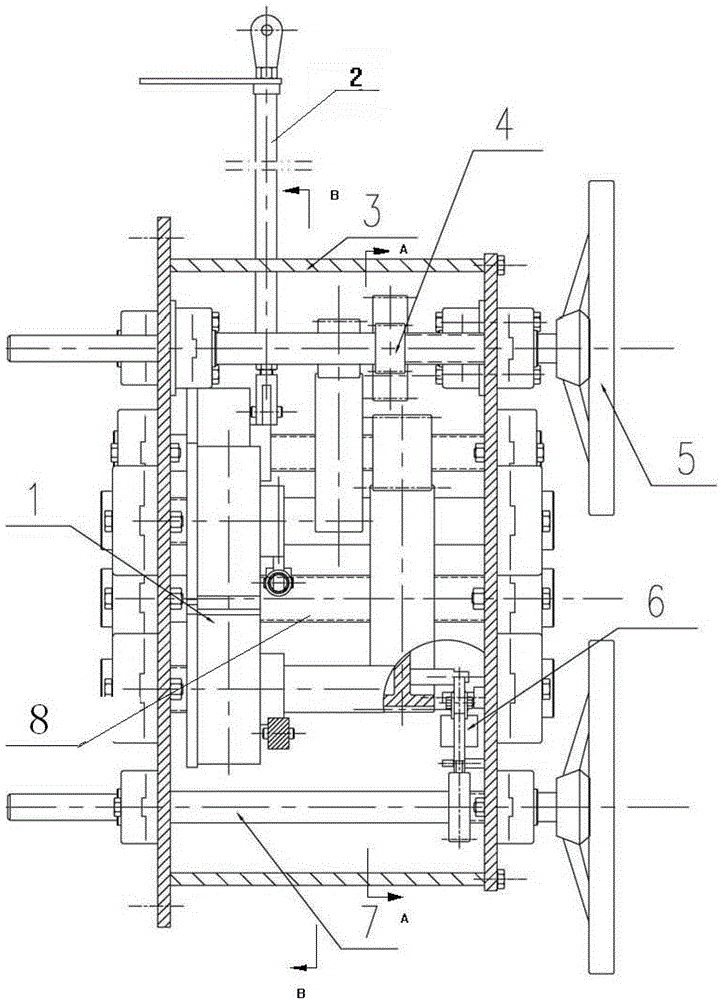

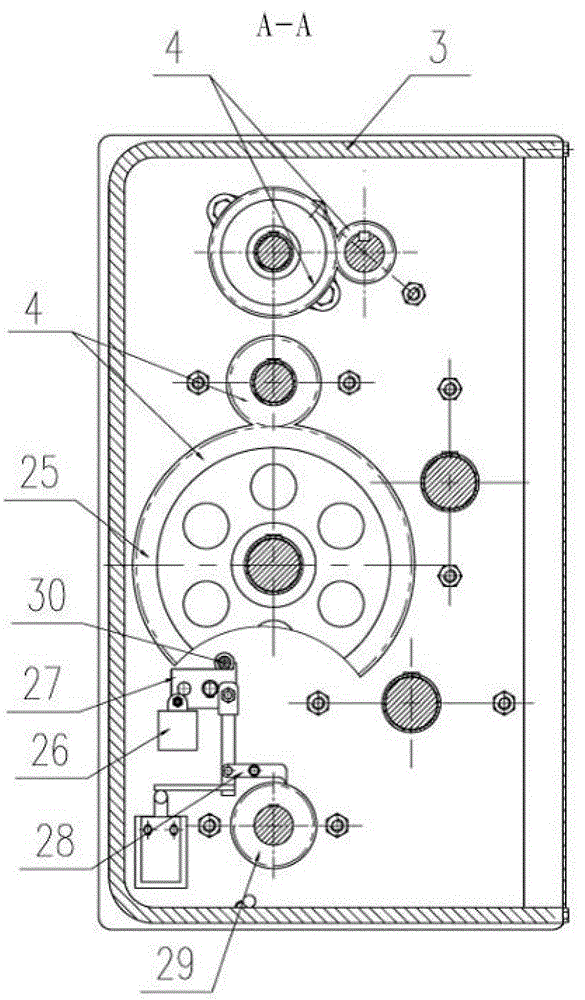

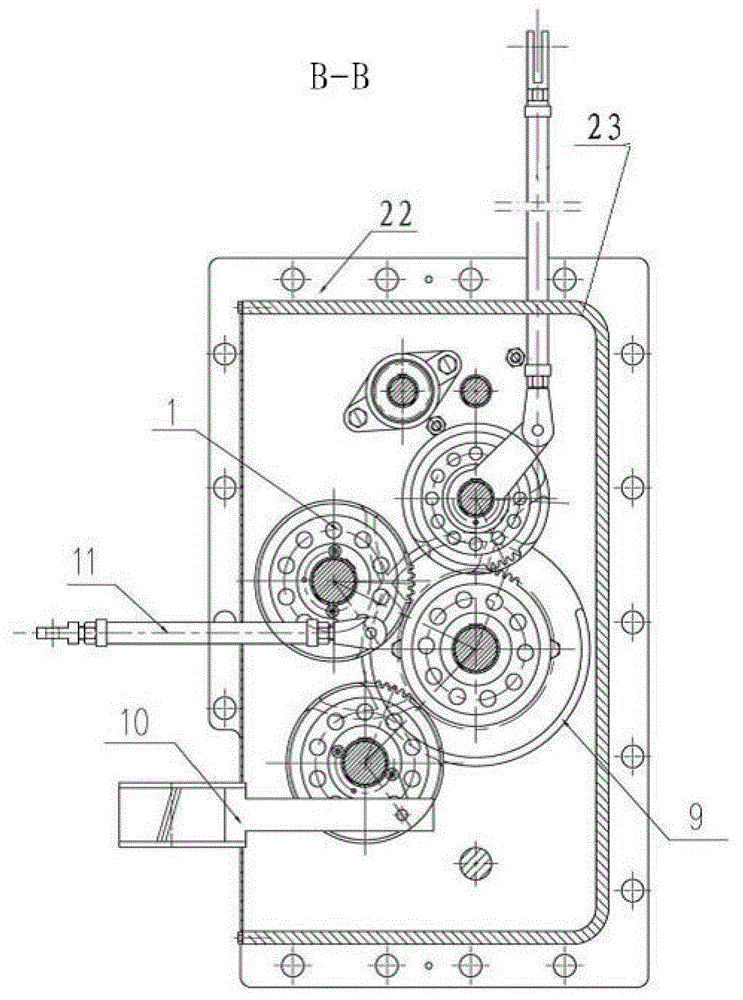

[0041] a kind of like Figure 1 to Figure 9 The transmission boxes on both sides of the personnel gate shown mainly include box body 3, transmission gear set 4, incomplete gear set 1, interlock device 6, transmission shaft 7, bearing seat 24, handwheel 5, connecting rod I (balance valve ) 2, connecting rod II (locking) 11 and rack 10. The box body 3 is a welded structure, which has undergone seismic analysis and meets the seismic requirements of nuclear power plants. The rear cover plate 21 and the box body plate 22 are welded together, the front cover plate 23 is detachable, fixed on the box body plate 22 by bolts, the bearing seat 24 is installed on the rear cover plate 21 and the front cover plate 23, the left side of the box body The side panels are detachable for observation and installation and debugging.

[0042]All transmission gears and incomplete gears are fixed on the front cover plate 23 and the rear cover plate 21 of the box through their respective axles. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com