Separated steel plate shear wall

A steel plate shear wall and separation technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of small bearing capacity and deformation, limited use range, etc., and achieve the effect of preventing steel plate buckling, small size and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

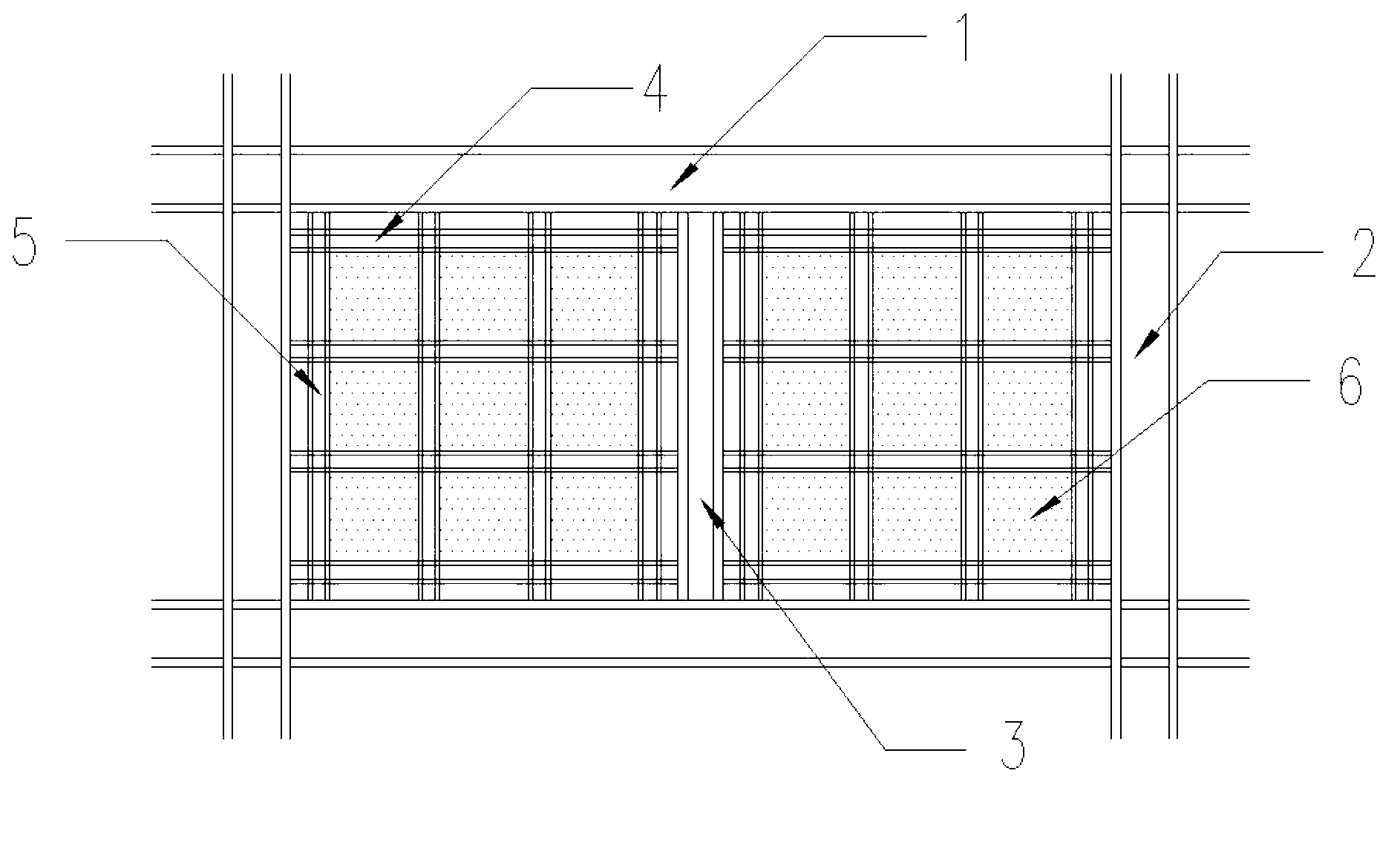

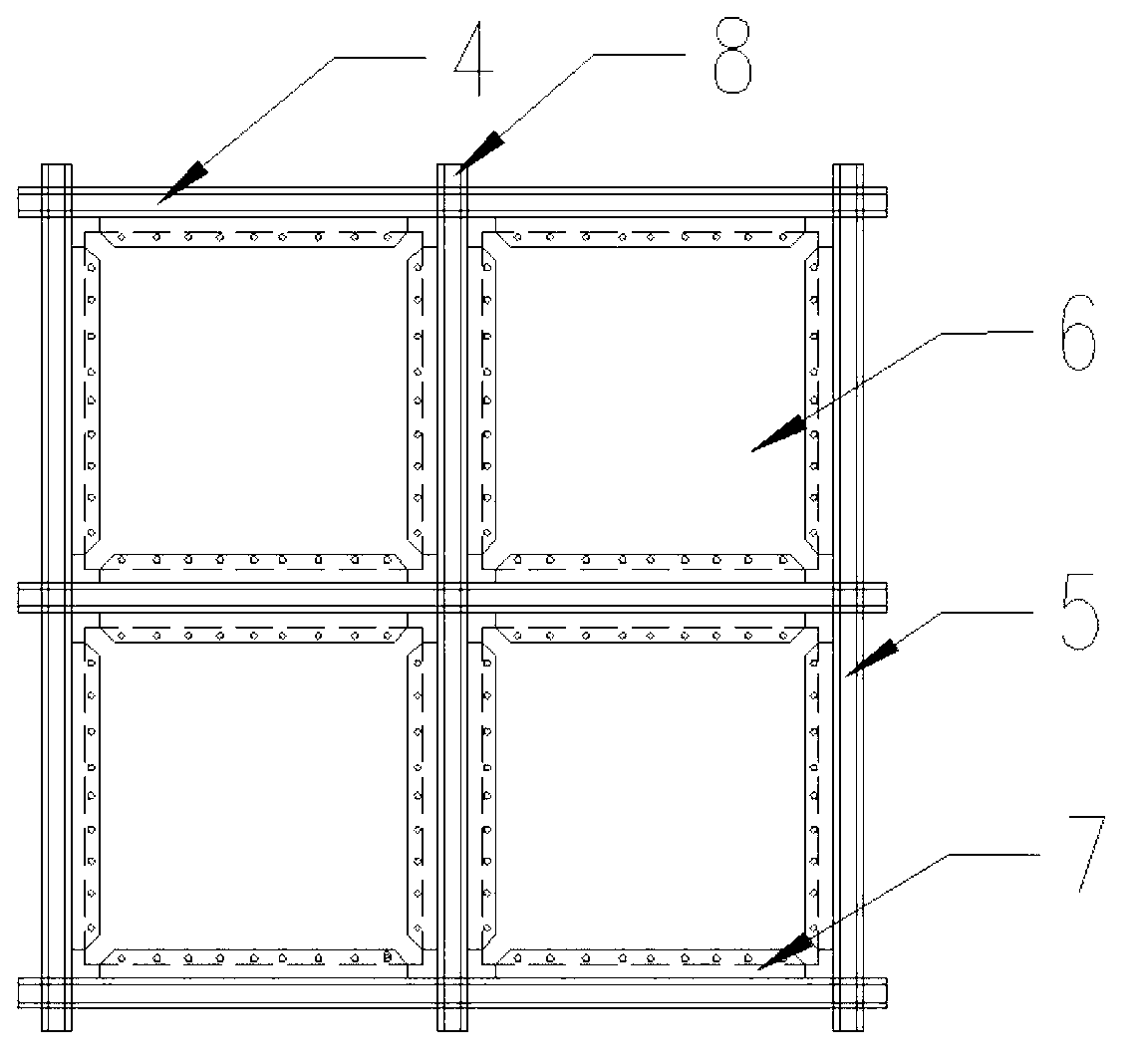

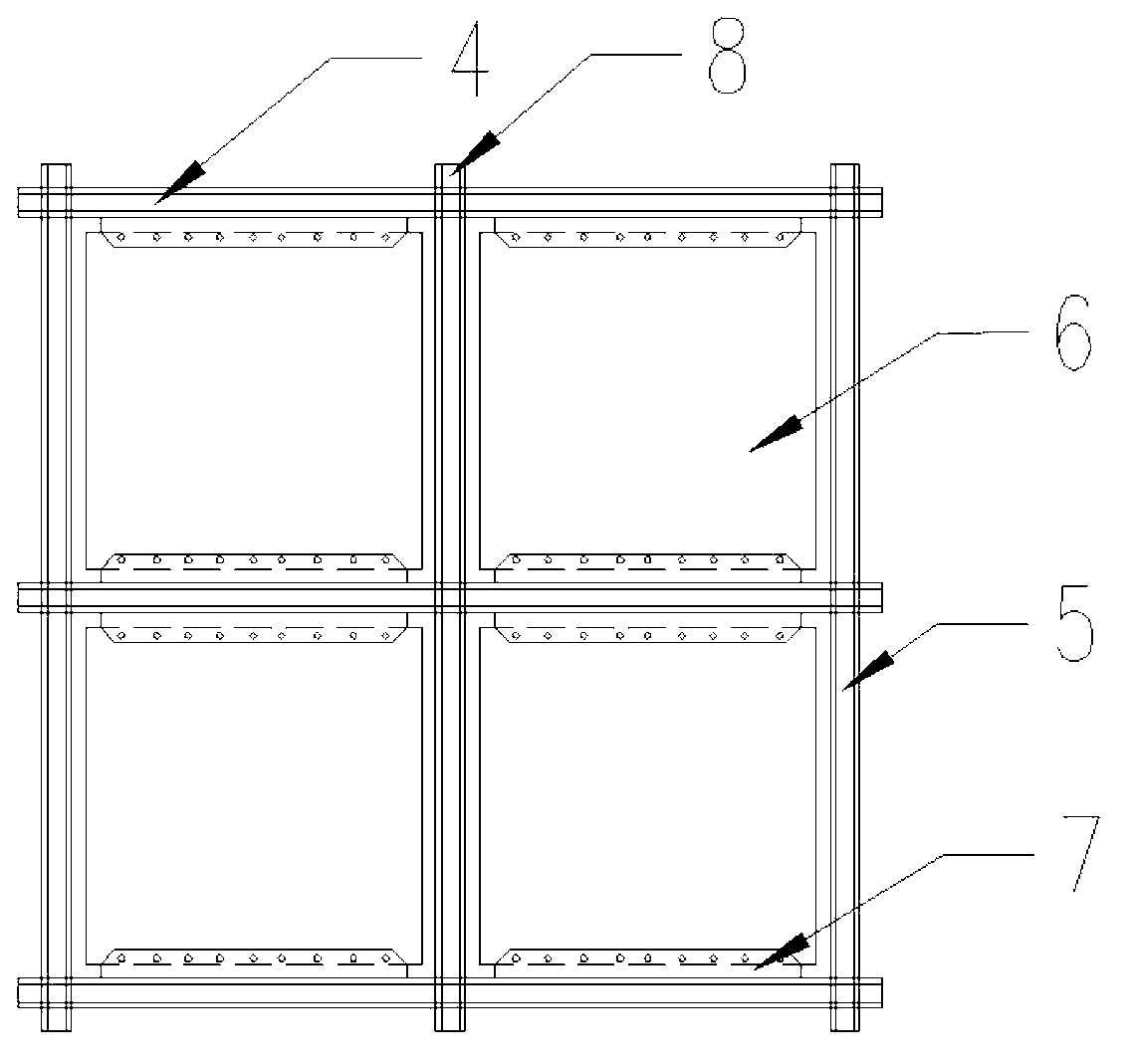

[0026] to combine figure 1 As shown in Fig. 2, the separated steel plate shear wall of the present invention comprises a rectangular unit framework composed of sash beams 4 and sash columns 5, and embedded steel plates 6 are installed in each grid of each rectangular unit framework; Both the sash beam 4 and the sash column 5 are made of light steel. Each sash beam 4 and sash column 5 is made of light steel: ① hot-rolled light steel (H-beam, I-beam, L-beam and T-beam); ② welded light-gauge steel (H-beam, I-beam, L-beam and T-beam ); ③ thin-walled steel pipe (round tube, square tube and rectangular tube); ④ cold-formed thin-walled steel; ⑤ components welded by thin steel plates.

[0027] As shown in Figure 2, the rectangular unit skeletons of each steel plate shear wall are three-beam and three-column structures, four-beam and four-column structures, five-beam and five-column structures, four-beam and three-column structures, or three-beam and four-column structures. The width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width size | aaaaa | aaaaa |

| Height dimension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com