Method of purifying biogas into natural gas

A bio-natural gas and natural gas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of complex composition of bio-natural gas and non-compliance with the quality requirements of natural gas for vehicles, achieve significant environmental and ecological benefits, and promote benign development , the effect of promoting circular economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

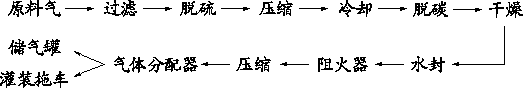

Image

Examples

Embodiment 1

[0030] The biological natural gas produced by the anaerobic digestion of wastewater is desulfurized first by PDS wet method, washed with lye, and then enters the decarbonization device after desulfurization. Under different pressures and temperatures, CO 2 and CH 4 have different solubilities, CO 2 The solubility is much greater than that of CH 4 , under the working pressure of 0.9MPa absorption tower, choose the appropriate spray water flow rate and temperature to make CH 4 The recovery rate is maximized.

[0031] The raw material gas passes through the filter to remove dust and mechanical impurities. After desulfurization, it is compressed to 0.9MPa (A) in the compressor, cooled to 40°C by the refrigerant, and enters the absorption tower for water washing and separation. The spray water of the absorption tower comes from the chiller, and the bottom water returns to the atmospheric desorption tower to release CO 2 Finally, it is pressurized by the water pump, and the chil...

Embodiment 2

[0035] The biological natural gas produced by the anaerobic digestion of wastewater is desulfurized first by PDS wet method, washed with lye, and then enters the decarbonization device after desulfurization. Under different pressures and temperatures, CO 2 and CH 4 have different solubilities, CO 2 The solubility is much greater than that of CH 4 , select the appropriate working pressure of the absorption tower (0.9MPa) and the flow rate and temperature of the spray water to make CH 4 The recovery rate is maximized.

[0036] The raw material gas passes through the filter to remove dust and mechanical impurities, is compressed to 0.9MPa (A) in the compressor after desulfurization, and is cooled to 35°C by the refrigerant and enters the absorption tower for water washing and separation. The spray water of the absorption tower comes from the chiller, and the bottom water returns to the atmospheric desorption tower to release CO 2 Finally, it is pressurized by the water pump, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com