Gas, liquid and solid three-phase separator for sewage anaerobic biological treatment

A three-phase separator and biochemical treatment technology, which is applied in the field of solid three-phase separator, liquid and gas, can solve the problems of poor separation effect and influence of solid phase granular sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawings and examples.

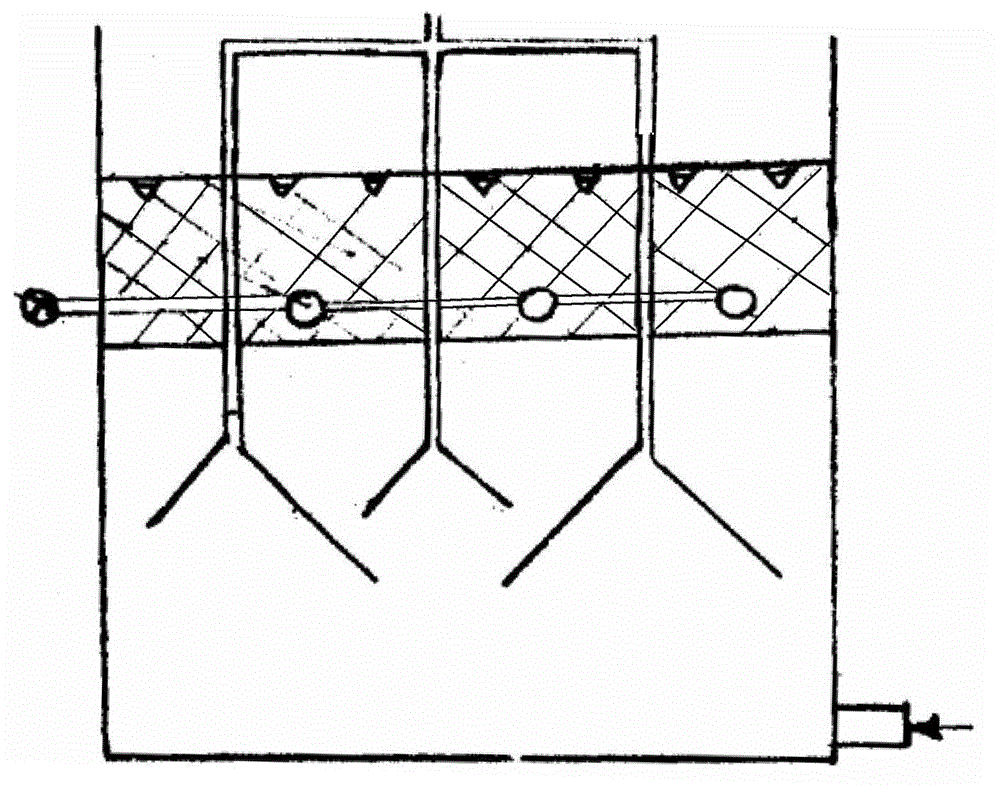

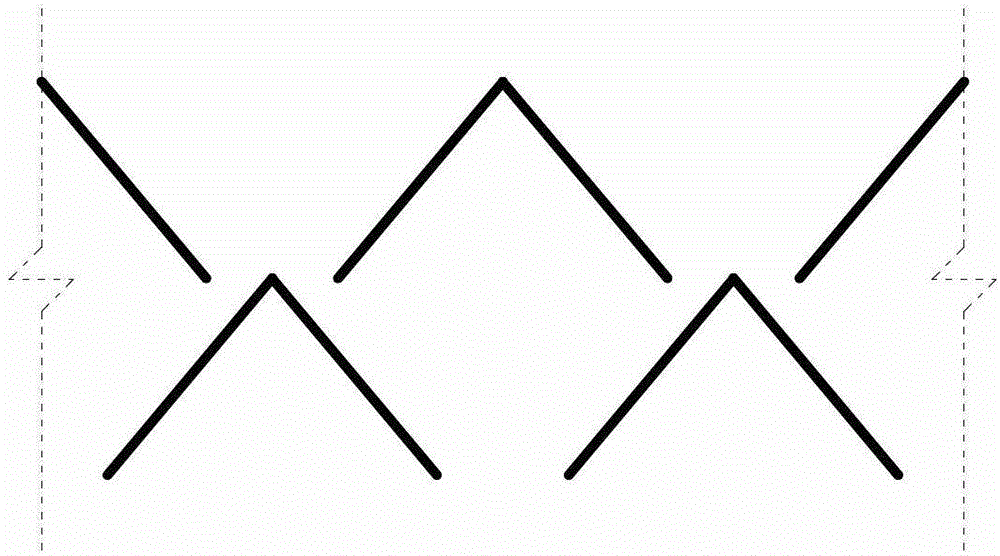

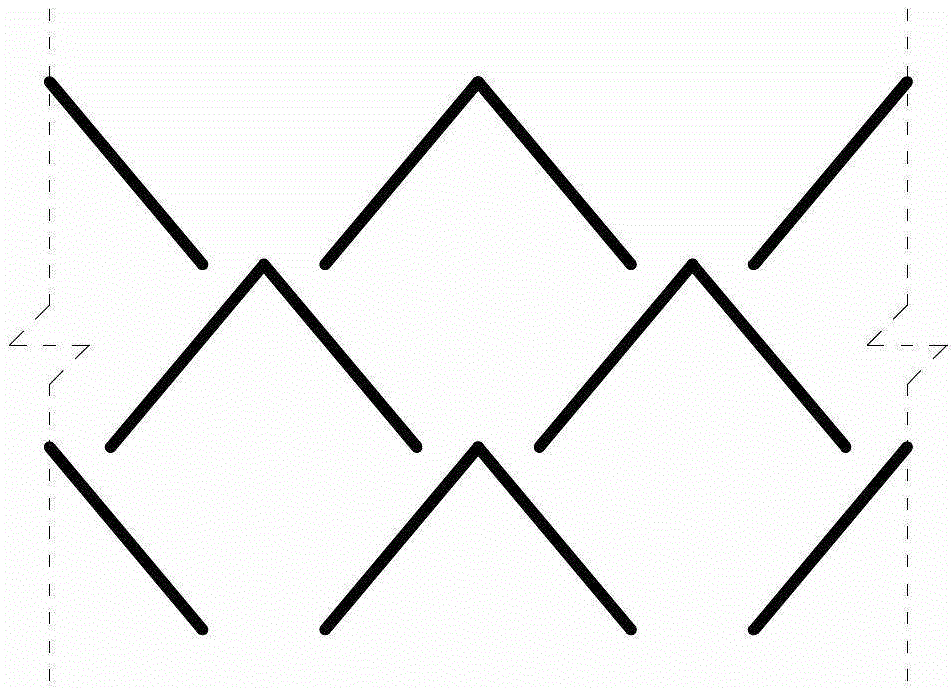

[0049] Such as image 3 As shown, the gas, liquid and solid three-phase separator used in the anaerobic biochemical treatment of sewage includes several single-layer inverted triangular gas collection chambers 1, and each single-layer inverted triangular gas collection chamber 1 is equipped with Two symmetrical L-shaped deflectors arranged in a figure-eight shape, and the lengths of the L-shaped deflectors below the adjacent single-layer inverted triangular plenum 1 are not equal, and the longer L-shaped deflector It is called the L-shaped long deflector 2, and the shorter L-shaped deflector is called the L-shaped short deflector 3, and both are collectively called the L-shaped deflector; the two adjacent L-shaped long deflectors A complete independent sludge settlement area 5 is formed between the plate 2 and the L-shaped short deflector 3; the gap between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com