Core-pulling self-locking mechanism

A self-locking and core-pulling technology, applied in the field of injection molds, can solve the complex problems of the whole set of molds, achieve the effect of simple core-pulling mechanism, reduce processing difficulty and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

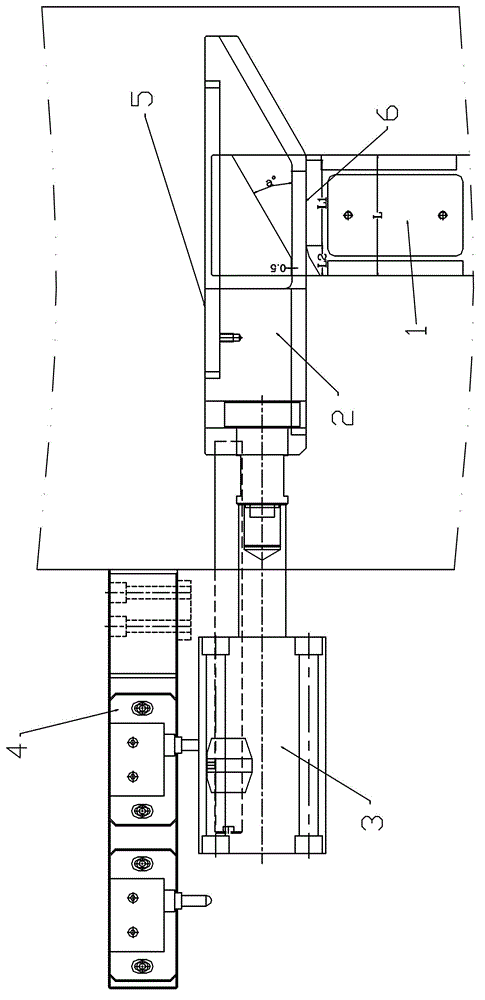

[0019] With reference to the accompanying drawings, a core-pulling self-locking mechanism includes a core-pulling 1 , a core-pulling dial 2 and a core-pulling driving device 3 . The above-mentioned core-pulling driving device is preferably a hydraulic cylinder (oil cylinder), and the stroke switch mechanism 4 can be used to control its stroke. Or release the core-pulling to make it move accordingly, and the movement directions between the core-pulling block and the core-pulling are perpendicular to each other. The above-mentioned core-pulling is placed in the core-pulling T-shaped slot, the top surface of the core-pulling T-shaped slot is a flat surface, the core-pulling block includes a wedge-shaped head and a straight section of the block, and the bottom end surface of the straight section of the block is a flat surface. During the mold closing process, the core-pulling driving device pushes the core-pulling block forward, and the core-pulling block is used to force the core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com