Automatic screwdriving machine

An automatic screw machine and screw gun technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult product consistency, affecting screw quality, damage to products or machines, etc., and achieves good economy The effect of benefit, product consistency and good quality, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

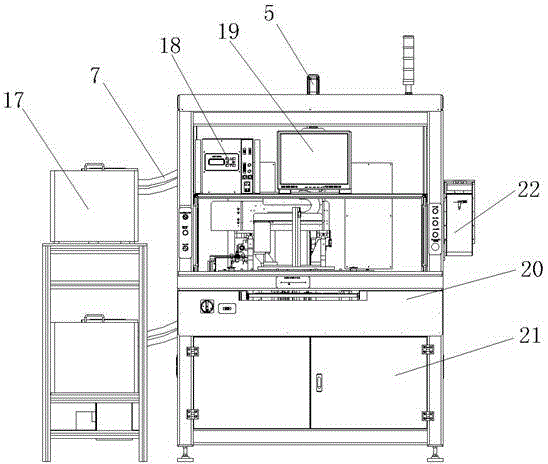

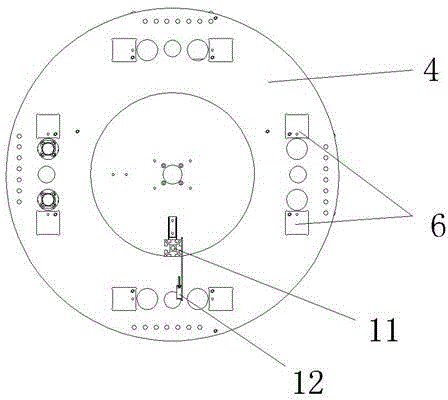

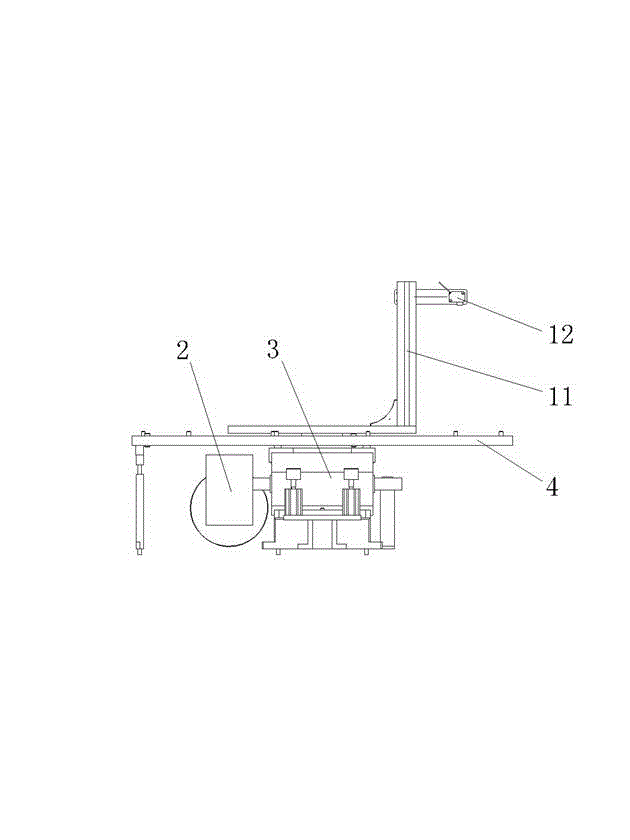

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention discloses an automatic screwdriver, comprising a mounting plate 1 and an electrical control system, the mounting plate 1 is made of iron plate processing, and the electrical control system includes a PLC controller, an operating platform 18, a display 19. Both the operating platform 18 and the display 19 are electrically connected to the PLC controller, through which the PLC controller can write the program instructions used by the screwdriver during work, and these program instructions are used to control the screwdriver. The specific operations of each part of the screwdriver can be operated on the operating platform 18, and the running state of the screwdriver can be displayed on the display 19, which is convenient for the staff to observe. The mounting plate 1 is provided with a motor 2, a splitter 3, a turntable 4, a screw gun 5 and a feeding mechanism, the motor 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com