Welding fixture

A technology for welding fixtures and top plates, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as high labor costs, inaccurate solder joints, and increased costs, achieve accurate solder joints, and improve quality The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

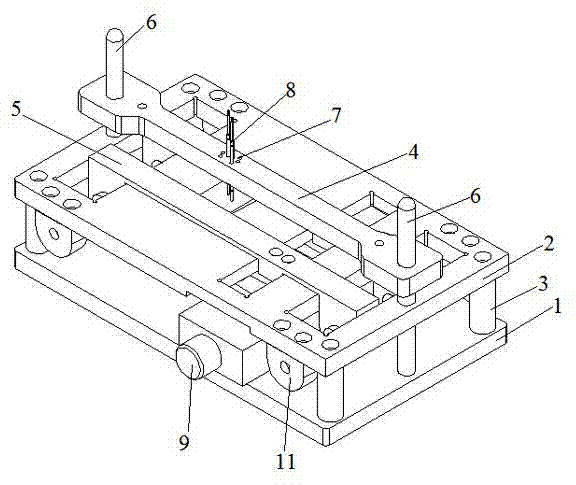

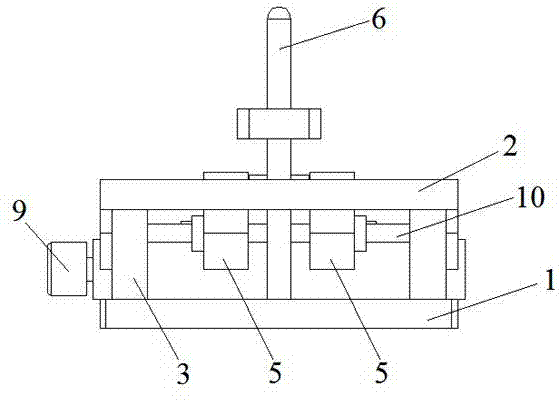

[0014] see figure 1 and figure 2 , a welding jig of the present invention includes a bottom plate 1 and a top plate 2, and the bottom plate 1 and the top plate 2 are connected by a mounting column 3. It also includes: a needle plate 4, a pair of splints 5, a guide post 6 for its positioning function, and an adjustment mechanism. Wherein, the pinhole 7 for inserting the probe 8 is formed on the needle plate 4 and is installed on the guide post 6. In this way, the guide post 6 can effectively play the role of positioning the needle plate 4 to ensure that it is located at the same position. on flat surface.

[0015] In order to automatically adjust the position of the product to be welded, the adjustment mechanism of the present invention includes: an adjustment knob 9 and a positive and negative screw rod 10 that drives the splint 5 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com