Pipe fitting clamping mechanism

A pipe clamping and pipe clamping technology, which is applied to metal processing equipment, stripping devices, manufacturing tools, etc., can solve problems such as unsafety, low efficiency, and high labor intensity, and achieve high production efficiency, stable operation, and automatic production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

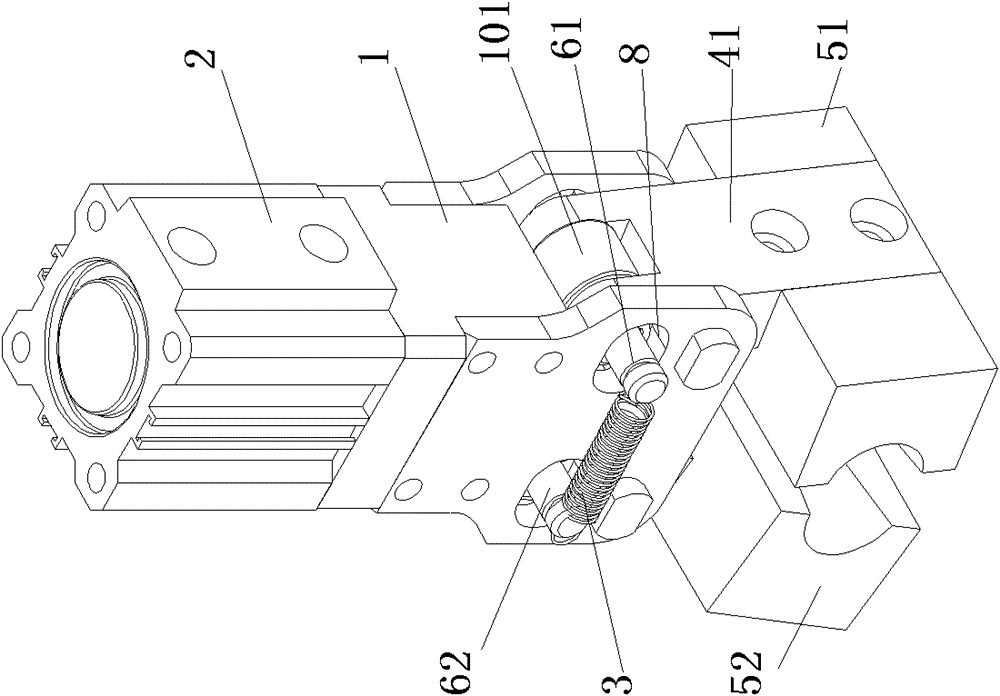

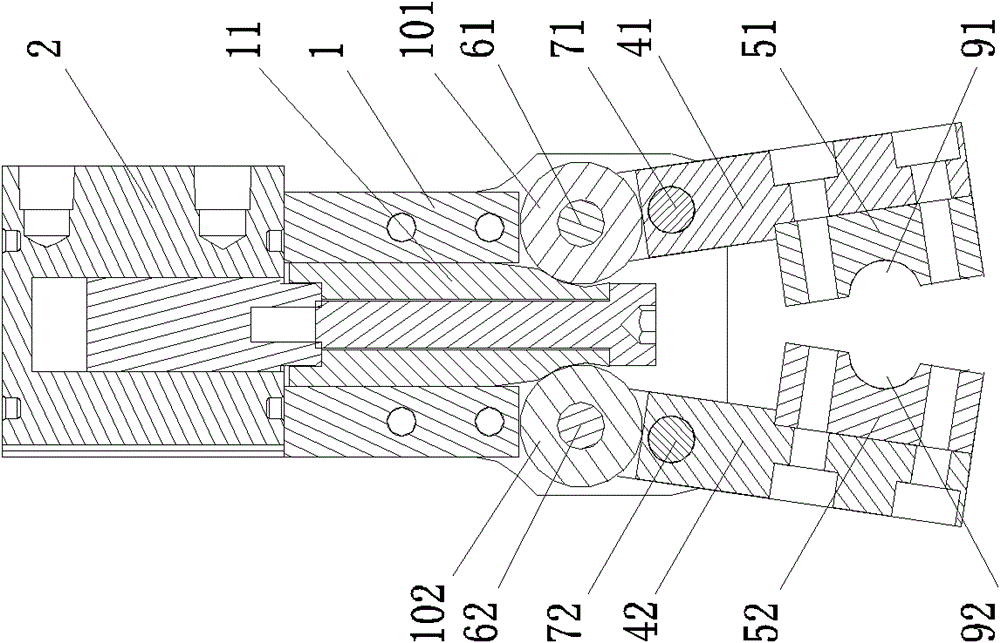

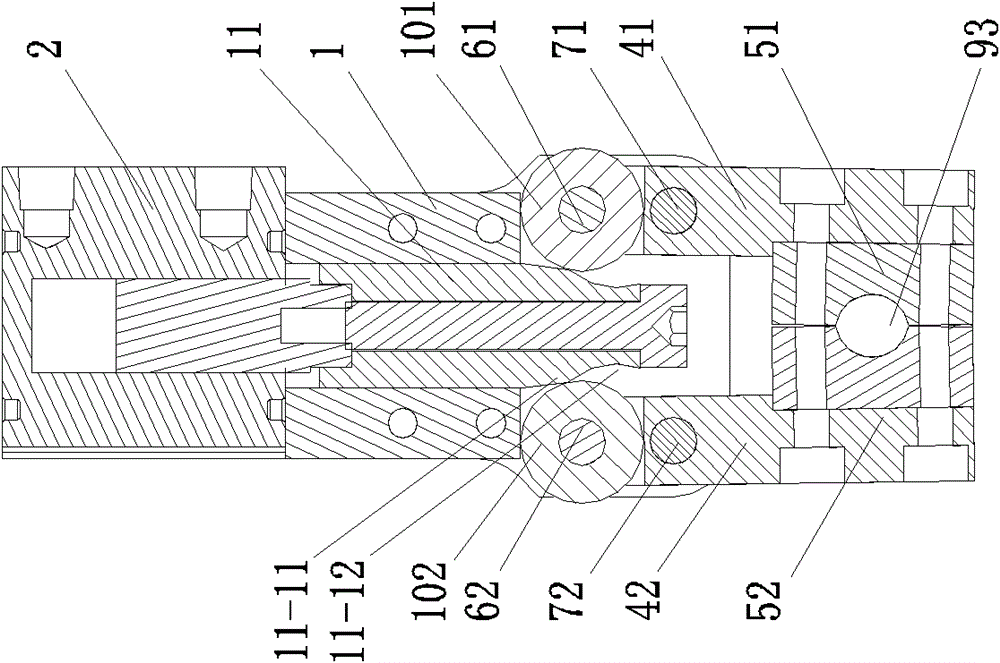

[0015] Embodiment: A clamping mechanism for pipe fittings, including a machine base 1, a push cylinder 2, a return spring 3, a first finger arm 41, a second finger arm 42, a first clamping block 51, a second clamping block 52, a second A pin shaft 61 , a second pin shaft 62 , a first fixed pin shaft 71 and a second fixed pin shaft 72 .

[0016] The two ends of the first finger arm 41 are installed with the first pinch block 51 and the first pin shaft 61 respectively, and the two ends of the second finger arm 42 are respectively installed with the second pinch block 52 and the second pin shaft 62. A chute 8 is provided, and the two ends of the first pin shaft 61 and the second pin shaft 62 protrude from the chute 8 and are connected to the corresponding ends by the return spring 3 , the first pin shaft 61 and the second pin shaft 62 are in the Slide on the chute 8, the first finger arm 41 and the second finger arm 42 are hinged on the base 1 through the first fixed pin shaft 71...

Embodiment approach

[0019] As another embodiment of the present invention, the first roller 101 and the second roller 102 are bearings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com