Preparing method of wide-width pure titanium roll

A technology of pure titanium and coils, applied in the direction of manufacturing tools, welding equipment, metal rolling, etc., can solve the problems of lack of large-scale promotion and application, slow development of titanium welded pipes, etc., and achieve the elimination of camber phenomenon and the quality of welds Excellent, guaranteed uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the wide-width pure titanium coil of the present embodiment comprises the following steps:

[0027] Step 1. The TA1 pure titanium slab with a thickness of 5mm, a width of 1560mm, and a length of 10m is subjected to atmospheric annealing treatment, and after cooling in the furnace, pickling removes the surface scale; the temperature of the atmospheric annealing treatment is 650°C, and the atmospheric annealing The processing time is 15 minutes;

[0028] Step 2: Plasma weld 20 pure titanium slabs after pickling in step 1 with a plasma welder to obtain a pure titanium welded slab with a width of 1560 mm and a length of 200 m, and then use a winder to weld the pure titanium slabs The welded slab is wound up to obtain a pure titanium coil; the current of the plasma welding is 185A, and the speed of the plasma welding is 330mm / min;

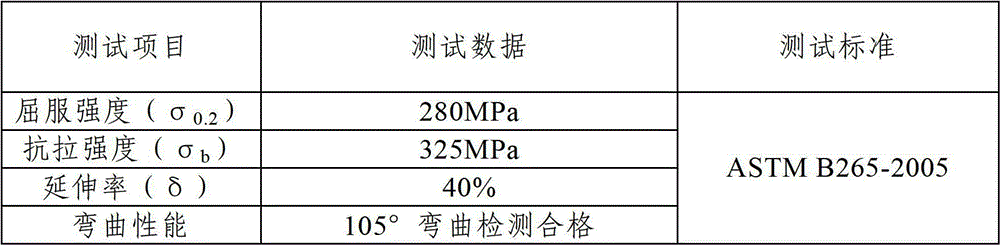

[0029] Step 3. Use the 1780mm six-high reversing cold rolling mill produced by Antai Technology Co., Ltd. to carry ou...

Embodiment 2

[0036] The preparation method of the wide-width pure titanium coil of the present embodiment comprises the following steps:

[0037] Step 1. The TA2 pure titanium slab with a thickness of 2 mm, a width of 1400 mm, and a length of 9.5 m is subjected to atmospheric annealing treatment, and after cooling in the furnace, pickling removes the surface scale; the temperature of the atmospheric annealing treatment is 680 ° C, the atmosphere The annealing time is 10min;

[0038]Step 2: Plasma weld 14 pure titanium slabs after pickling in step 1 by plasma welding machine to obtain a pure titanium welded slab with a width of 1400 mm and a length of 133 m, and then use a winder to weld the pure titanium slabs The welded slab is wound up to obtain a pure titanium coil; the plasma welding current is 160A, and the plasma welding speed is 300mm / min;

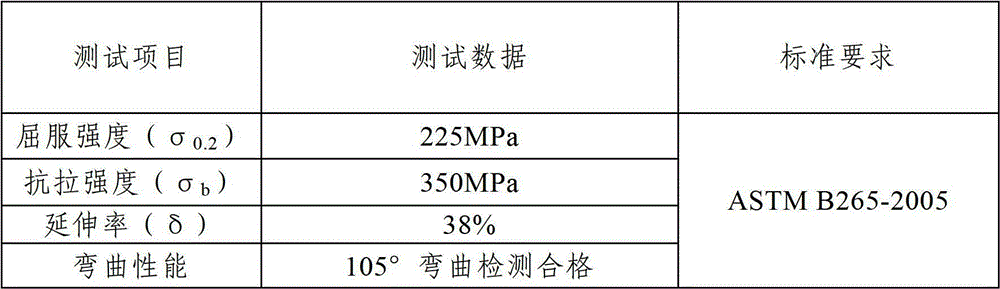

[0039] Step 3. Use the 1780mm six-high reversing cold rolling mill produced by Antai Technology Co., Ltd. to carry out 15 passes of rolling on...

Embodiment 3

[0046] The preparation method of the wide-width pure titanium coil of the present embodiment comprises the following steps:

[0047] Step 1. The TA1 pure titanium slab with a thickness of 1 mm, a width of 1250 mm, and a length of 9.8 m is subjected to atmospheric annealing treatment, and after cooling in the furnace, pickling removes the surface scale; the temperature of the atmospheric annealing treatment is 650 ° C, the atmosphere The annealing time is 20min;

[0048] Step 2: Plasma weld 18 pure titanium slabs after pickling in step 1 by plasma welding machine to obtain a pure titanium welded slab with a width of 1250 mm and a length of 176.4 m, and then use a winder to wind the pure titanium slabs The titanium welding slab is rolled up to obtain a pure titanium coil; the current of the plasma welding is 250A, and the plasma welding speed is 350mm / min;

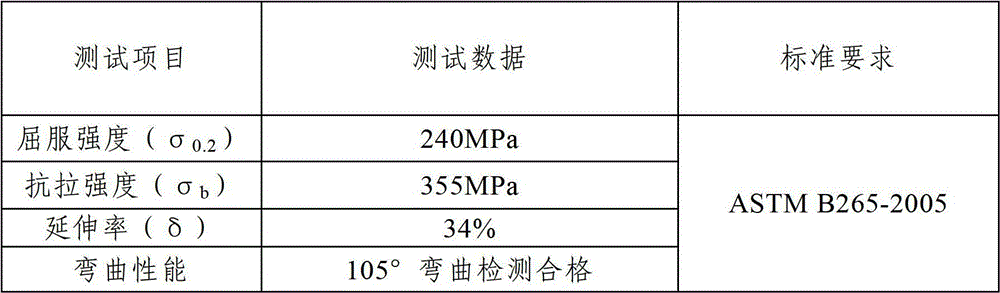

[0049] Step 3. Use the 1780mm six-high reversing cold rolling mill produced by Antai Technology Co., Ltd. to carry out 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com