Compound water treatment agent and preparation method and application of water treatment agent

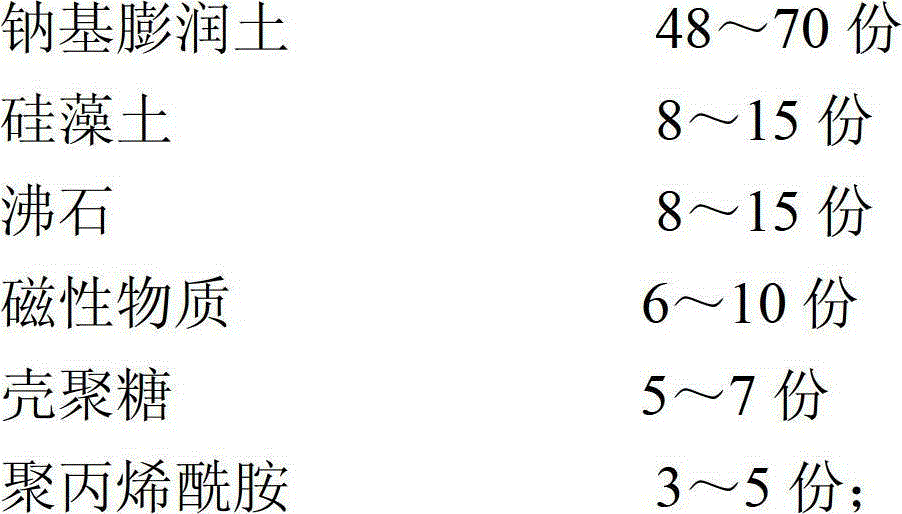

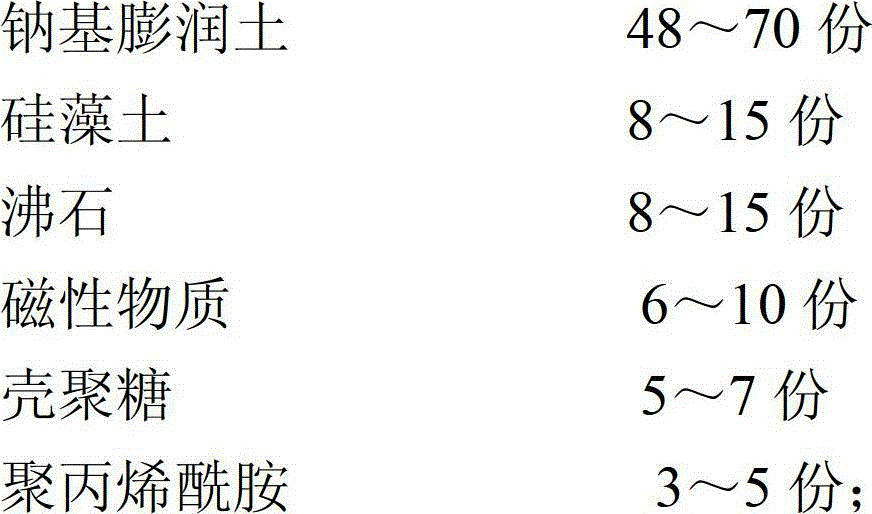

A water treatment agent and compound technology, applied in the field of composite water treatment agent and its preparation, can solve the problem of inability to comprehensively remove heavy metal ions and organic pollutants, failure to consider how to synergistically remove organic pollutants, inability to achieve rapid separation, etc. To achieve the effect of speeding up the adsorption equilibrium speed, significant adsorption effect, and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The magnetic substance is separated from the smoke and dust discharged from the iron and steel plant by using a magnet block with a magnetic field strength of 1000-1500Gs. The separated magnetic substance is in the state of sol aggregation in the gaseous state of the smoke and dust, and in the state of brown-red powder in the dry state. Particle size is less than 100μm, specific magnetic susceptibility x 0 >12.6×10 -8 m 3 / kg of magnetic particles; after X-ray diffraction analysis, the main active ingredient is γ-F 2 o 3 , using chemical analysis to analyze the magnetic particles, Fe 2 o 3 The content (wt%) is 95.3% to 98.6%.

[0038] The purified sodium bentonite, diatomite and zeolite natural mineral products with a particle size of 150-200 meshes are selected for use.

Embodiment 2

[0040] (1) Weigh 35g of sodium bentonite, 4g of diatomaceous earth, 4g of zeolite and 3g of magnetic substance in Example 1 and place them in a 2000ml Erlenmeyer flask, add water to make a suspension with a weight concentration of 8%, and stir evenly.

[0041] (2) Add 250ml of chitosan solution with a weight concentration of 1% to the suspension obtained in step (1), stir at 45°C for 5 hours, then filter with suction, wash with water, dry at 95°C, crush and After passing through a 100-mesh sieve, a powdery substance was obtained.

[0042] (3) Take 48.5g of the powdery substance obtained in step (2) and add it to 150ml of polyacrylamide solution with a weight concentration of 1%, continue to stir at 50°C for 4 hours, then centrifuge at a speed of 1500r / min, water Washing, suction filtration and vacuum drying at 55°C to constant weight, and finally pulverized through a 100-mesh sieve to obtain powdery composite water treatment agent 1.

[0043] (4) Take 1g of the powdered compo...

Embodiment 3

[0045] (1) Weigh 24g of sodium bentonite, 7.5g of diatomaceous earth, 7.5g of zeolite and 5g of magnetic substance in Example 1 and place them in a 2000ml Erlenmeyer flask, add water to form a suspension with a weight concentration of 9%, and stir uniform.

[0046] (2) Add 175ml chitosan solution with a weight concentration of 2% to the suspension obtained in step (1), stir at 55°C for 5 hours, then filter with suction, wash with water, dry at 95°C and pulverize After 100-mesh sieve, a powdery substance was obtained.

[0047] (3) Take 47.5g of the powdery substance obtained in step (2) and add it to 250ml of polyacrylamide solution with a weight concentration of 1%, and continue to stir at 55°C for 5 hours, then centrifuge, wash, suction filter and 55 °C, vacuum-dried to constant weight, and finally crushed through a 100-mesh sieve to obtain powdery composite water treatment agent 2.

[0048] (4) Take 1g of the powdered composite water treatment agent 2 obtained in step (3) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific susceptibility | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com