A preparation method of a functional module for absorbing droplets and VOC in airflow

A functional module and droplet technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of large pressure drop of the gas distribution plate, large pressure drop, difficulty in completely eliminating oily smoke and VOC, etc., to achieve improved The effect of absorbency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

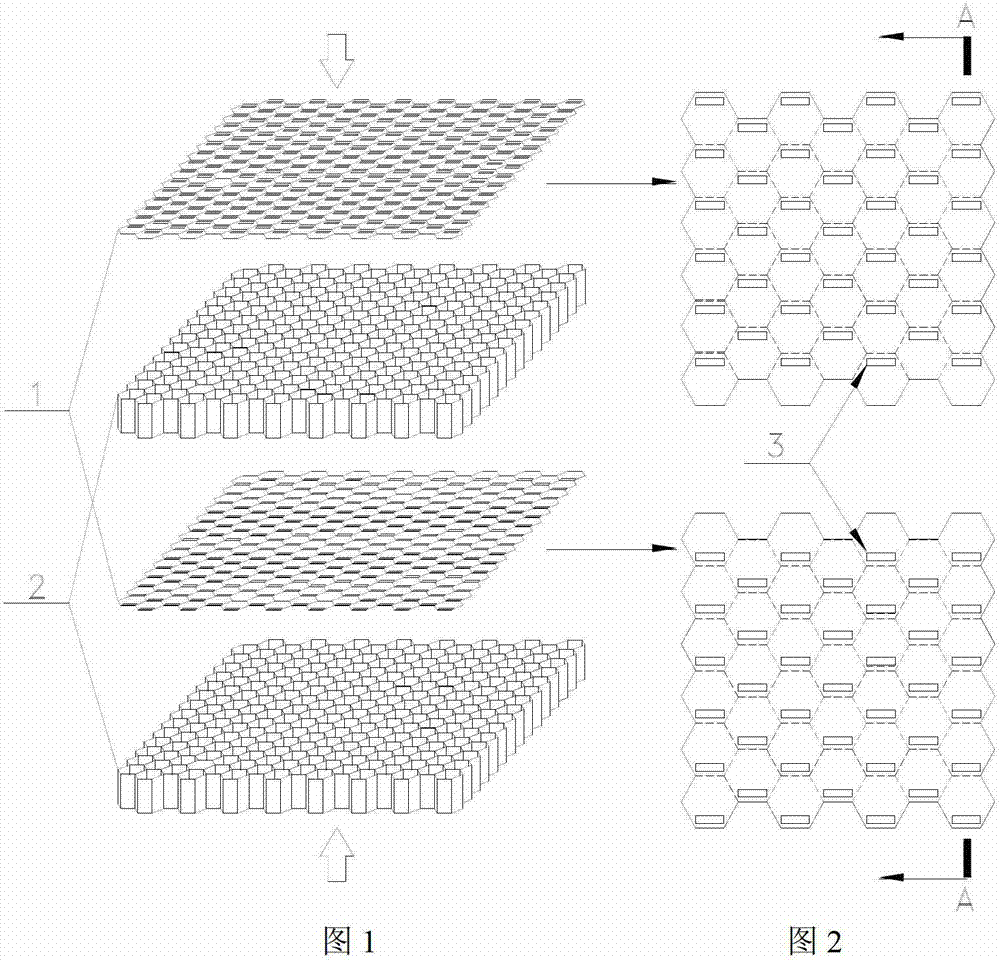

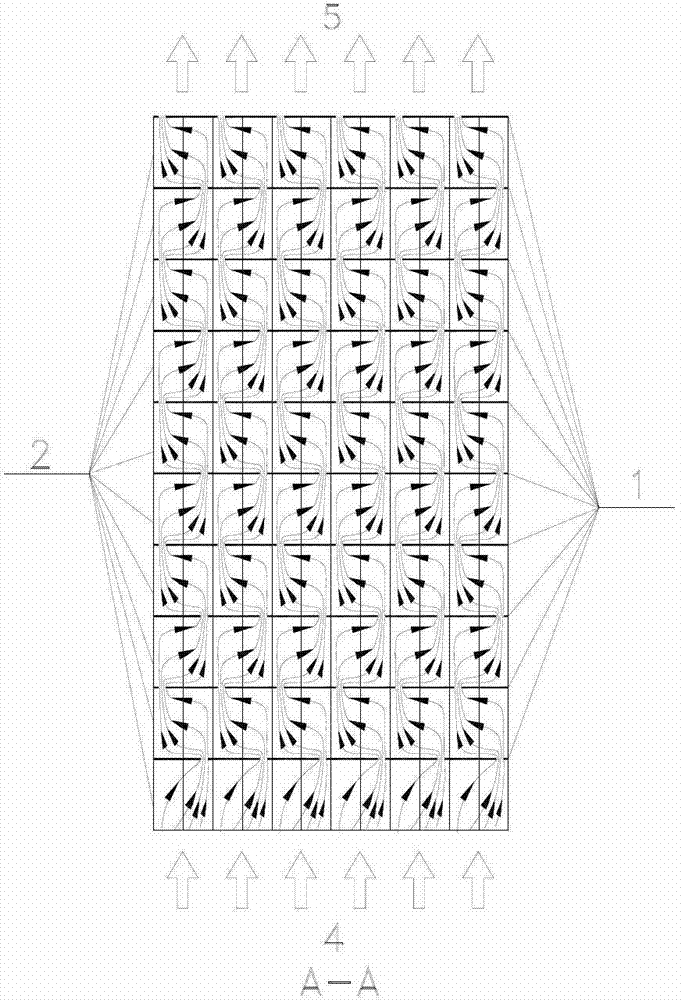

Embodiment 1

[0014] 取10块直径为200mm的圆形纸蜂窝板(分别含有10层蜂窝层和10层隔板层),每层纸蜂窝板的厚度为100mm,蜂窝层截面的正六边形的边长为4mm,在相邻隔板层的不同位置开孔,并将8层纸蜂窝板浸渍在含有30%硅藻土和0.1%聚乙烯醇(MW30万)的浆料中,取出后烘干,而另外2层纸蜂窝则浸渍在含有10%活性炭粉末和0.5%糊化淀粉的浆料中,取出后烘干,将负载硅藻土的纸蜂窝层安置在前,而将负载活性炭的纸蜂窝安置在后,便获得了可有效去除废气中雾滴和VOC的功能模块。

Embodiment 2

[0016] 取20块尺寸为300mm×300mm的正方形纸蜂窝板(分别含有20层蜂窝层和20层隔板层),每层纸蜂窝板的厚度为150mm,蜂窝层截面的正六边形的边长为10mm,在相邻隔板层的不同位置开孔,并将10层纸蜂窝板浸渍在含有50%膨胀蛭石粉和5%聚乙二醇(MW1000)的浆料中,取出后烘干,而另外10层纸蜂窝则浸渍在含有1%活性焦粉末和0.1%甲基纤维素的浆料中,取出后烘干,将负载蛭石粉的纸蜂窝层安置在前,而将负载活性焦的纸蜂窝安置在后,便获得了可有效去除废气中雾滴和VOC的功能模块。

Embodiment 3

[0018] 取30块直径为1000mm的纸蜂窝板(分别含有30层蜂窝层和30层隔板层),每层纸蜂窝板的厚度为200mm,蜂窝层截面的正六边形的边长为200mm,在相邻隔板层的不同位置开孔,并将22层纸蜂窝板浸渍在含有40%活性氧化铝粉和2%聚乙烯醇(MW2.5万)的浆料中,取出后烘干,而另外8层纸蜂窝则浸渍在含有20%短切活性炭纤维和0.1%阳离子醚化淀粉的浆料中,取出后烘干,将负载活性氧化铝的纸蜂窝层安置在前,而将负载短切活性炭纤维的纸蜂窝安置在后,便获得了可有效去除废气中雾滴和VOC的功能模块。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com