Robot for intelligent tracking ultrasonic detection of welding line, and software analysis system therefor

An ultrasonic testing and intelligent tracking technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis and material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of welding seam tracking, manual inspection, and detection data errors Larger problems, to achieve the effect of reducing dependence on technical level, reducing disputes, and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

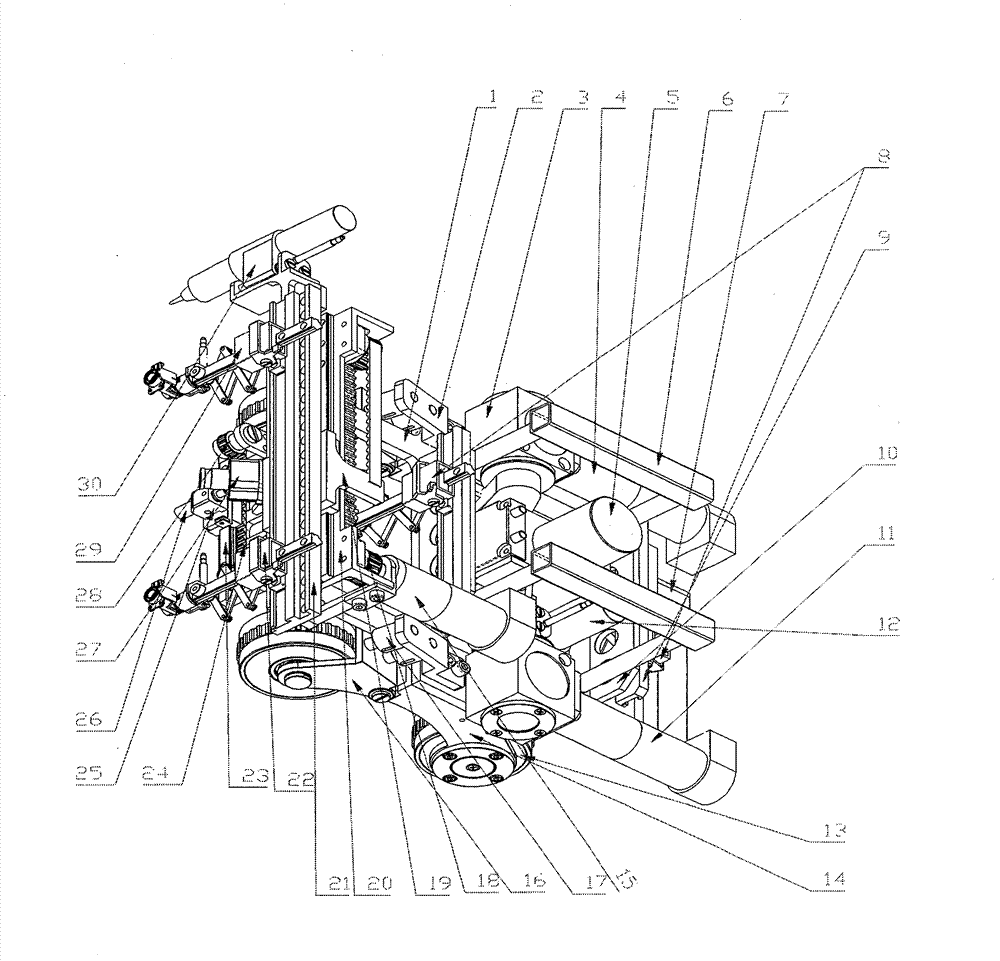

[0013] figure 1 It is the structure diagram of the welding seam intelligent tracking ultrasonic detection robot body, figure 1 Middle: 1 is the frame, and the vibration-damping beam frame 2 is installed on both sides of the frame 1, and is connected with the sub-wheel frame 16 through the vibration-damping kit 17 to provide free floating space for the front wheels to meet Climb over cross-weld obstacles and large drop obstacles. The angle transmission box 3 is also installed on both sides of the frame 1, and directly above the main wheel frame 14, the angle transmission box is composed of a casing, an end cover, a bevel gear, and a main transmission shaft, and the motor 4 and the motor 11 are respectively installed on the On the angular transmission box 3 on one side, the driving force of the motor is transmitted to the main running wheel 13 through the output shaft pulley and the synchronous belt of the angular transmission box. , bearings, synchronous pulleys, by starting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com