Fabric weft inclination detection method based on image analysis

A technology of image analysis and detection method, which is applied in the field of processing and time-frequency conversion technology and motion image acquisition, and can solve the problems of detection and identification dead angle, low detection accuracy, and inapplicability to thick fabrics or twill fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The fabric weft skew is mainly caused by the uneven tension of the yarn in the fabric during the finishing process. The weft skew of the fabric will lead to a decline in the quality of the finished textile. Therefore, there will be special weft adjustment equipment at the end of the finishing process. Complete the correction of weft skew. The weft adjustment process depends on the detection results of the weft skew angle. The weft skew detection process based on the photoelectric method has insufficient detection accuracy and is easily affected by external conditions.

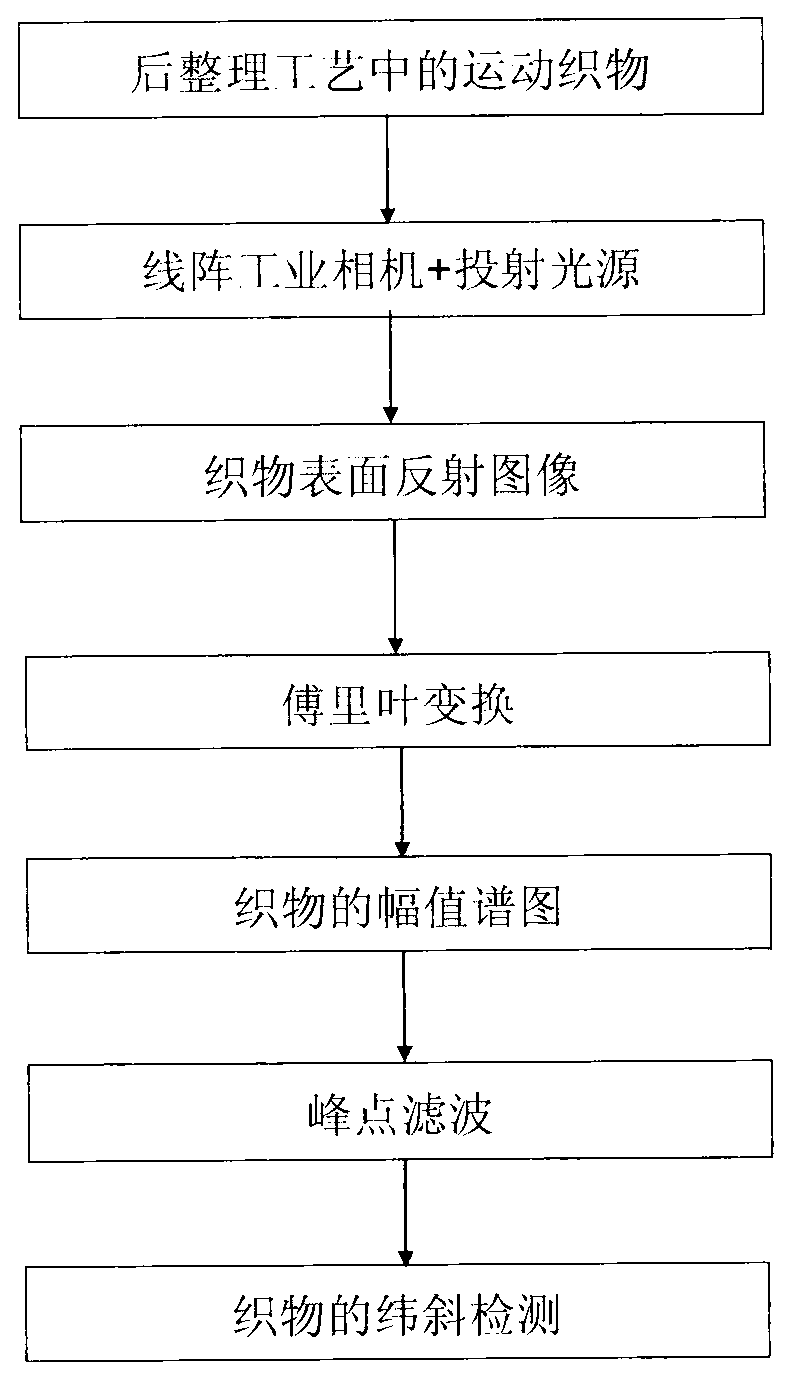

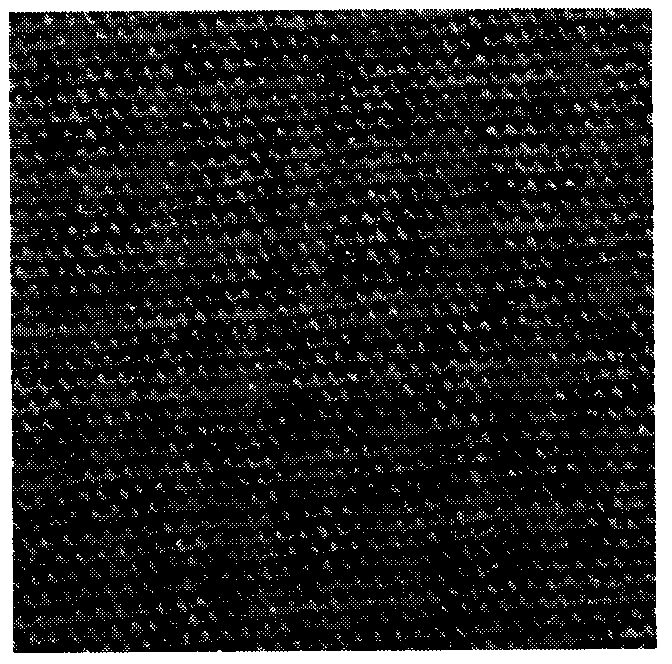

[0016] The invention provides a fabric weft skew detection method based on image analysis, the detection process is more stable, the specific implementation steps are as follows figure 1 shown. An implementation example is given below, figure 2 It is the fabric surface image collected by the current craft camera, and the industry provided by the system is projection type.

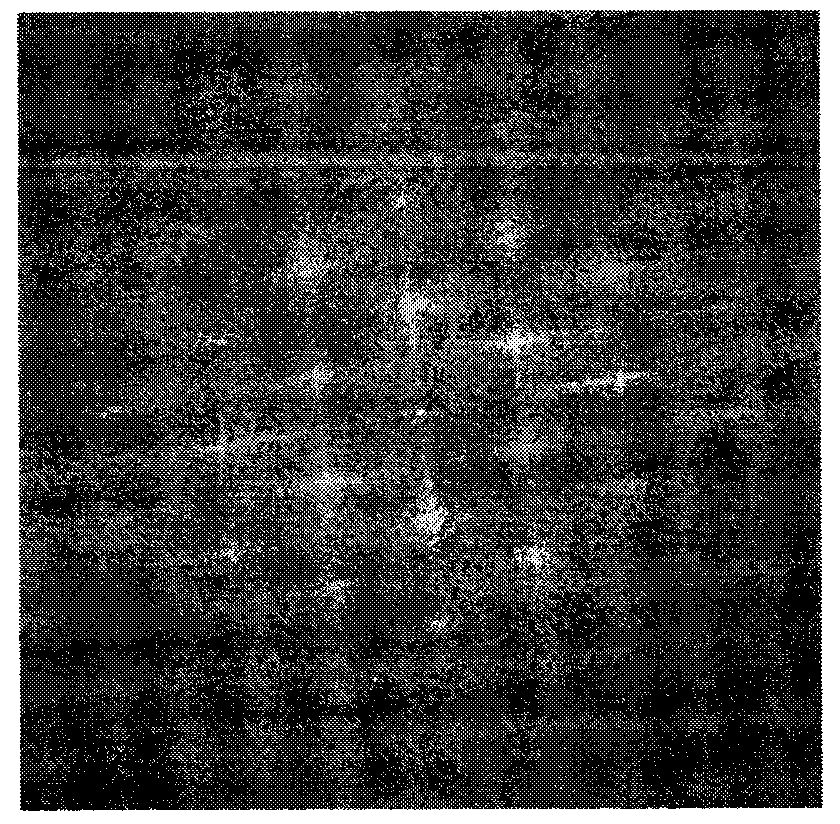

[0017] right figure 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com