Preheating and drying device for sterilizing filling equipment

A drying device and empty bottle technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of time-consuming, high production cost, and long filling process of dairy products, so as to reduce residual volume, The effect of improving efficiency and accelerating volatilization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

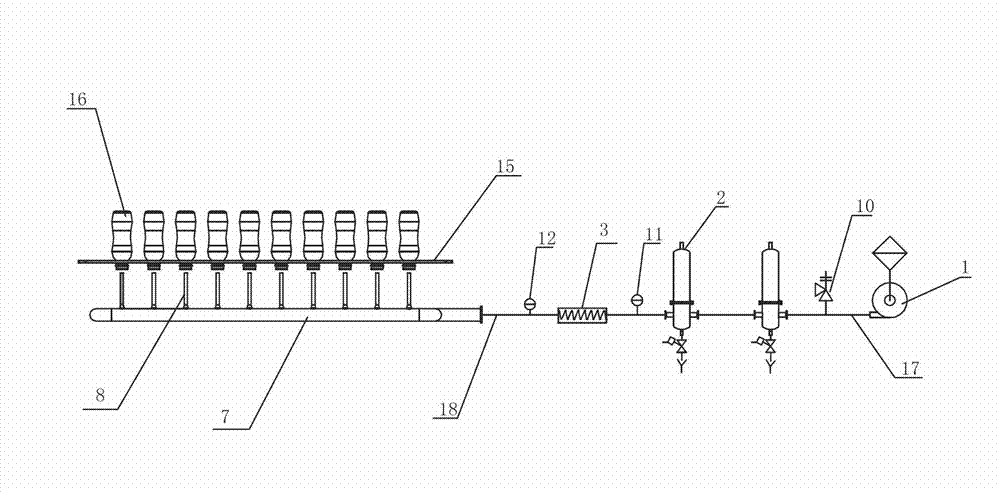

[0019] Refer to attached picture. The invention adopts high-temperature sterile air to heat the inner surface of the empty bottle that needs to be sterilized, so as to play the role of preheating. After the sterilization treatment, the inner surface of the empty bottle is reheated to accelerate the volatilization of water and the sterilization medium, and at the same time enhance the sterilization effect.

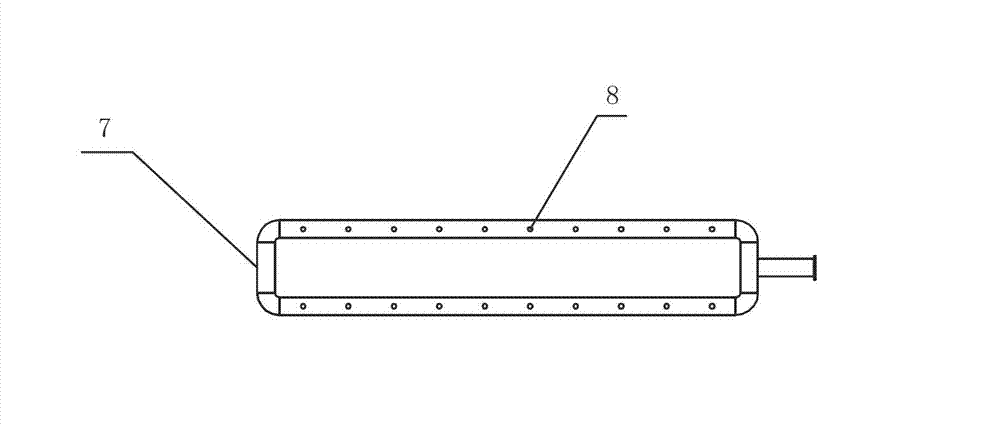

[0020] The preheating and drying device includes a sterile hot air delivery pipeline, an air filter 2 and a heater are arranged on the pipeline, and the air outlet end 18 of the pipeline is connected with an air spray unit, and the air spray unit includes a nozzle pipe 7 A plurality of nozzles 8 are arranged on the nozzle pipe 7, and the inlet end of the nozzle pipe 7 is connected with the gas outlet end 18 of the pipeline.

[0021] The inlet end 17 of the pipeline is connected with the blower 1 . The air blower 1 draws in air from the outside. There are two air filters 2...

Embodiment 2

[0029] With reference to the accompanying drawings, the difference between this embodiment and Embodiment 1 is that the empty bottle 16 is placed below the nozzle 7 during use, and the nozzle is arranged vertically downward. The empty bottle 16 is placed forwardly so that its bottle mouth is facing the nozzle, and there is an empty bottle correspondingly below each nozzle.

[0030] The spray pipe 7 is connected with the lifting mechanism. The lifting mechanism is a crank arm link mechanism 13 . The crank-link mechanism 13 is driven by the motor 14. When the motor starts, the crank of the crank-link mechanism 13 is driven to swing, and then the annular nozzle 7 moves up and down under the action of the connecting rod, driving the columnar nozzle 8 to extend into and out of the filled container. Inside the empty bottle. During use, the empty bottle 16 is placed on the bottom of the spray pipe 7, the nozzle 8 stretches into the inside of the bottle, and high-temperature sterile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com