Low-range circulating fluidized bed water boiler for combusting inferior fuel and combustion method thereof

A technology of circulating fluidized bed and hot water boiler, which is applied in the direction of fluidized bed combustion equipment, combustion method, and fuel burned in a molten state, can solve the problem of inability to reduce the carbon content of fly ash, low boiler thermal efficiency, water wall wear, etc. problems, to achieve the effects of improving combustion efficiency and thermal efficiency, reducing wear and reducing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

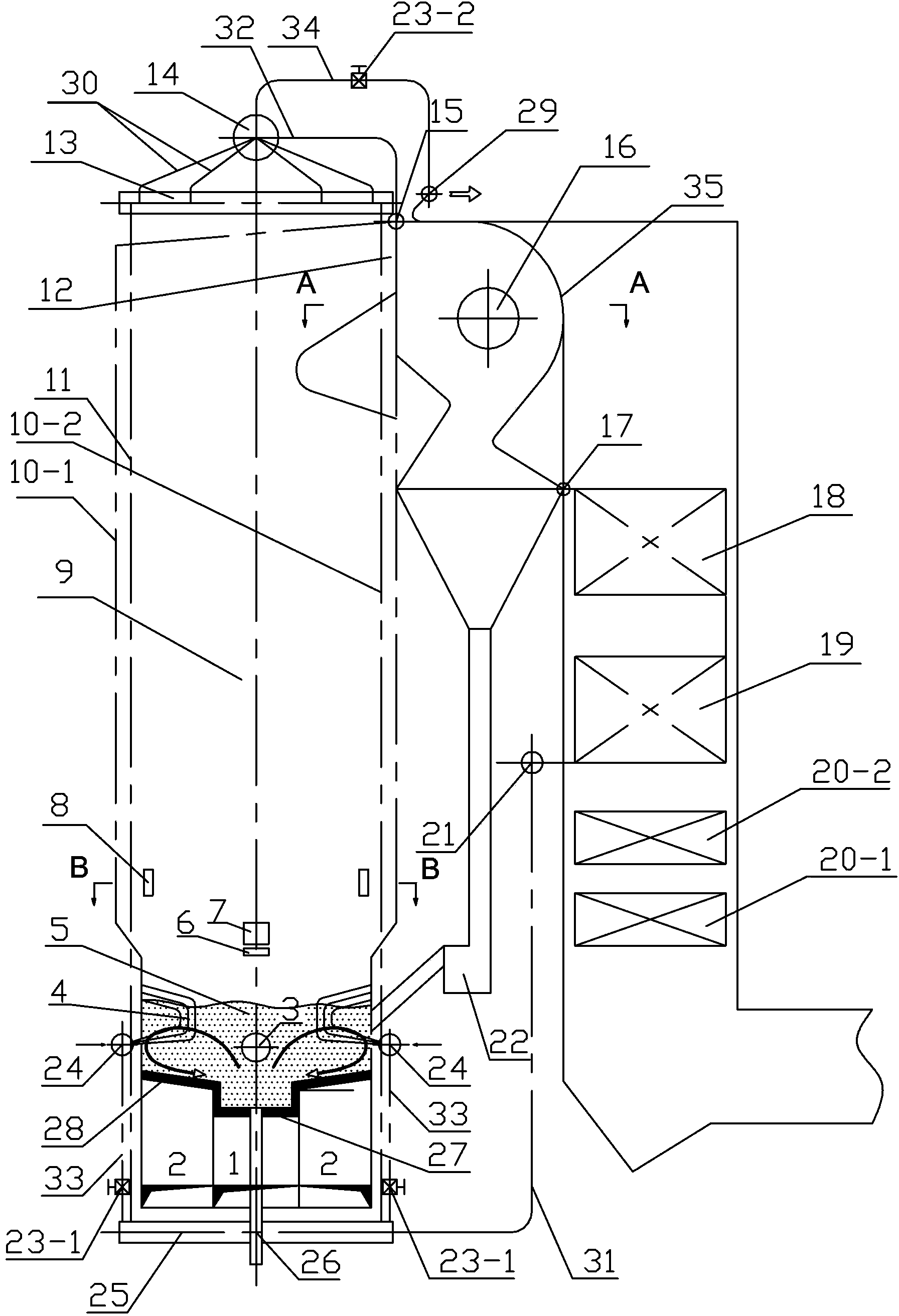

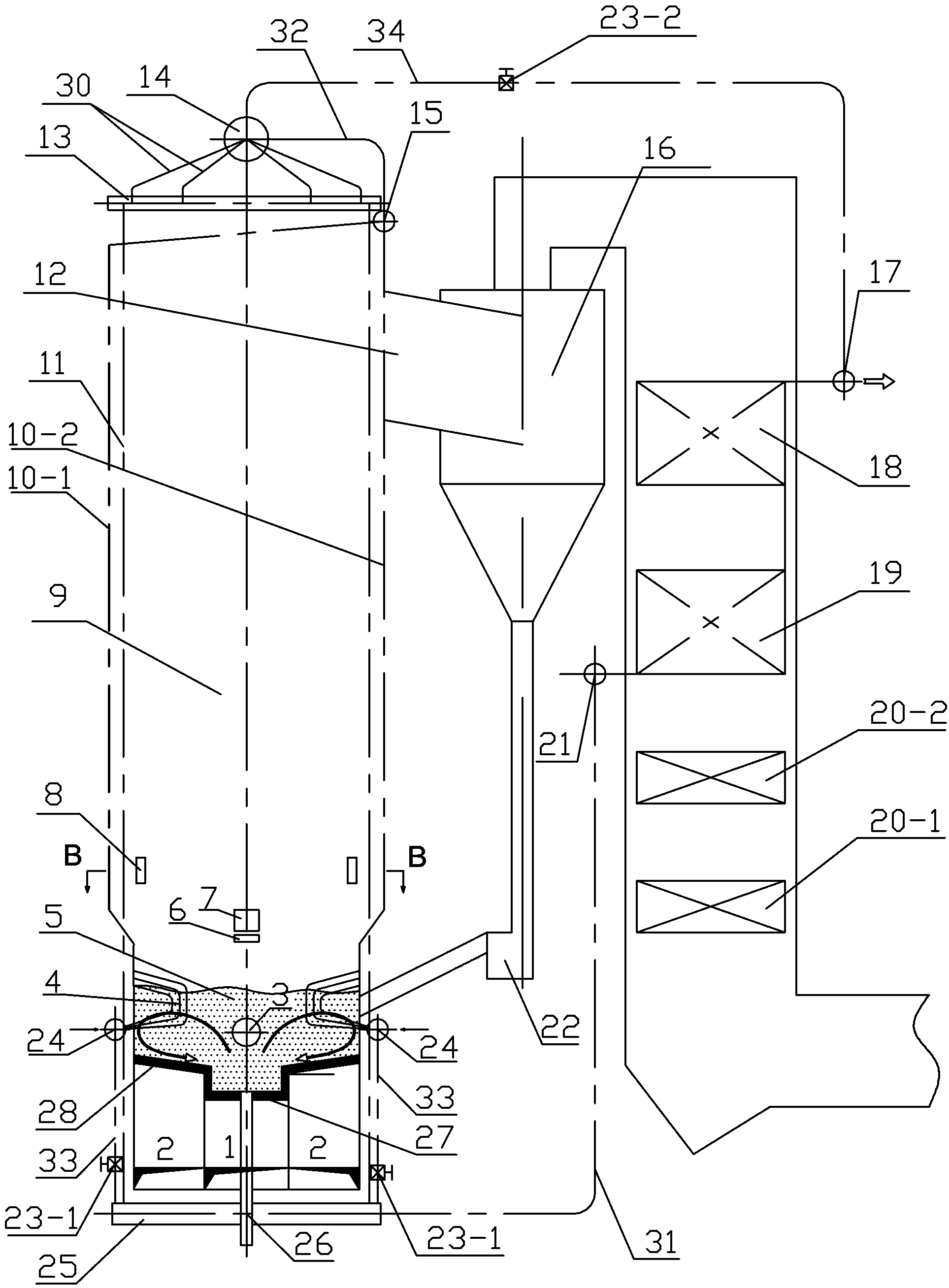

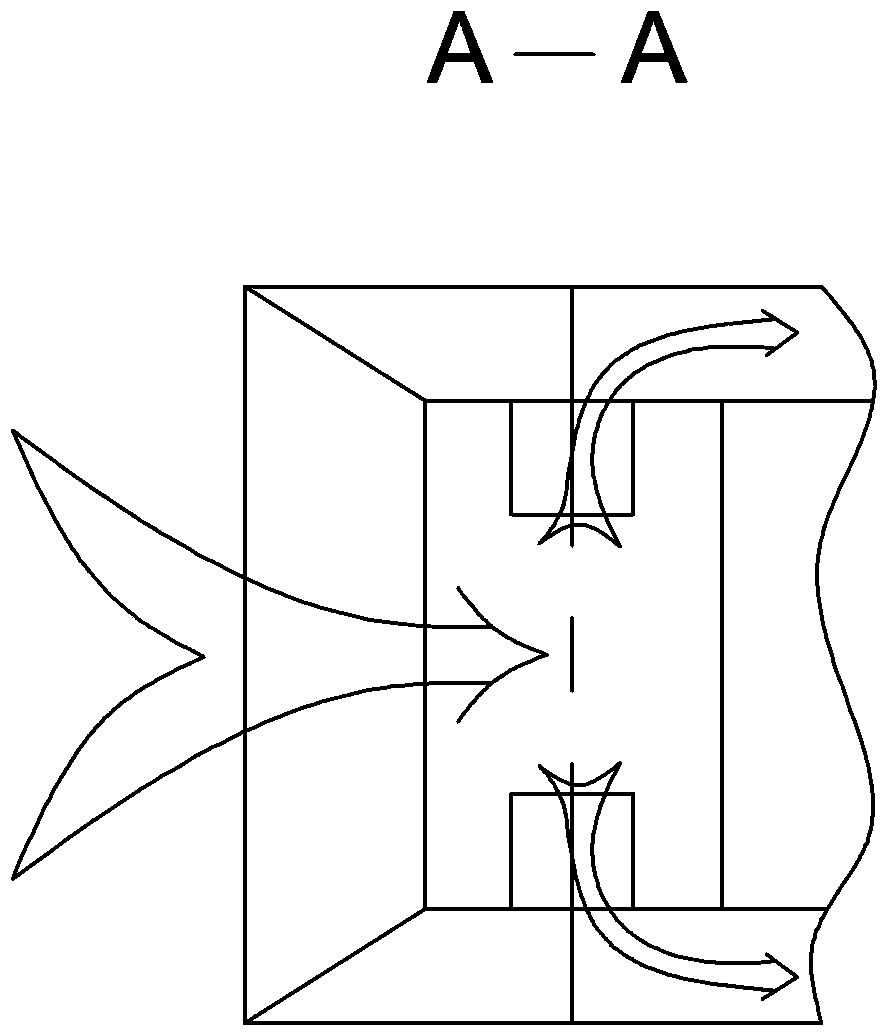

[0014] Specific implementation mode one: combine figure 1 and image 3 Describe this embodiment. A low-rate circulating fluidized bed hot water boiler that burns low-quality fuels in this embodiment includes a high-speed bed air chamber 1, two low-speed bed air chambers 2, a furnace door 3, buried pipes 4, and a dense phase area. 5. Coal sowing air 6, coal supply port 7, rotating air secondary air port 8, dilute phase area 9, front wall water cooling wall 10-1, rear wall water cooling wall 10-2, two side wall water cooling walls 11, furnace outlet 12. Header 13 on both sides of the water-cooled wall, drum 14, collection box 15 on the front and rear water-cooled walls, cyclone separator 16, high-temperature economizer outlet header 17, high-temperature economizer 18, and low-temperature economizer 19 , primary air air preheater 20-1, secondary air air preheater 20-2, low-temperature economizer inlet header 21, feeder 22, front and rear wall buried pipe lower header 24, water-c...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 Describe this embodiment, the fourth connecting pipe between the lower headers 24 of the front and rear wall buried pipes and the lower headers 25 of the water-cooled walls on both sides of a low-rate circulating fluidized bed hot water boiler that burns inferior fuels in this embodiment 33 is provided with a first valve 23-1, and the fifth connecting pipe 34 between the cyclone separator outlet header 29 and the drum 14 is provided with a second valve 23-2. The technical effect of this embodiment is: when sudden power failure occurs, the front wall water cooling wall 10-1, the rear wall water cooling wall 10-2, the two side wall water cooling walls 11 and the drum 14 in the furnace body, and the drum 14 and the The heated surface of the tail forms a natural circulation without water hammer. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 Describe this embodiment. The cyclone separator 16 of a low-rate circulating fluidized bed hot water boiler that burns low-quality fuel in this embodiment is a water-cooled horizontal cyclone separator with an acceleration section, and the outlet header 29 of the cyclone separator is a water-cooled horizontal cyclone separator with an acceleration section. The outlet header of the section water-cooled horizontal cyclone separator. The technical effects of this embodiment are: 1, because the separator is water-cooled, coking will not occur in the separator due to reburning; 2, the refractory material covered on the surface of the separator is thinner (about 100 mm), and the start-up time is relatively short ( 3-4 hours), saving fuel for the furnace; 3. According to needs, multiple separators can be evenly arranged at the furnace outlet, and the flue gas flow field is uniform; 4. The horizontal water-cooled cyclone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com