Balance pump

A technology for balancing pumps and pump bodies, which is applied to pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc. Problems such as limited blocking effect of the valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

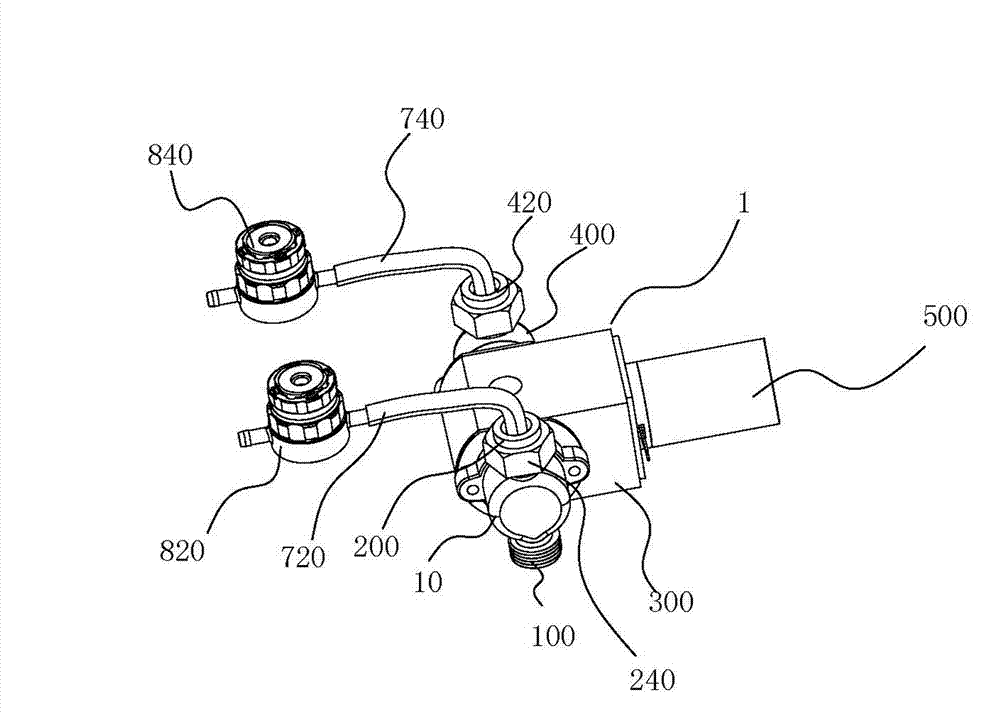

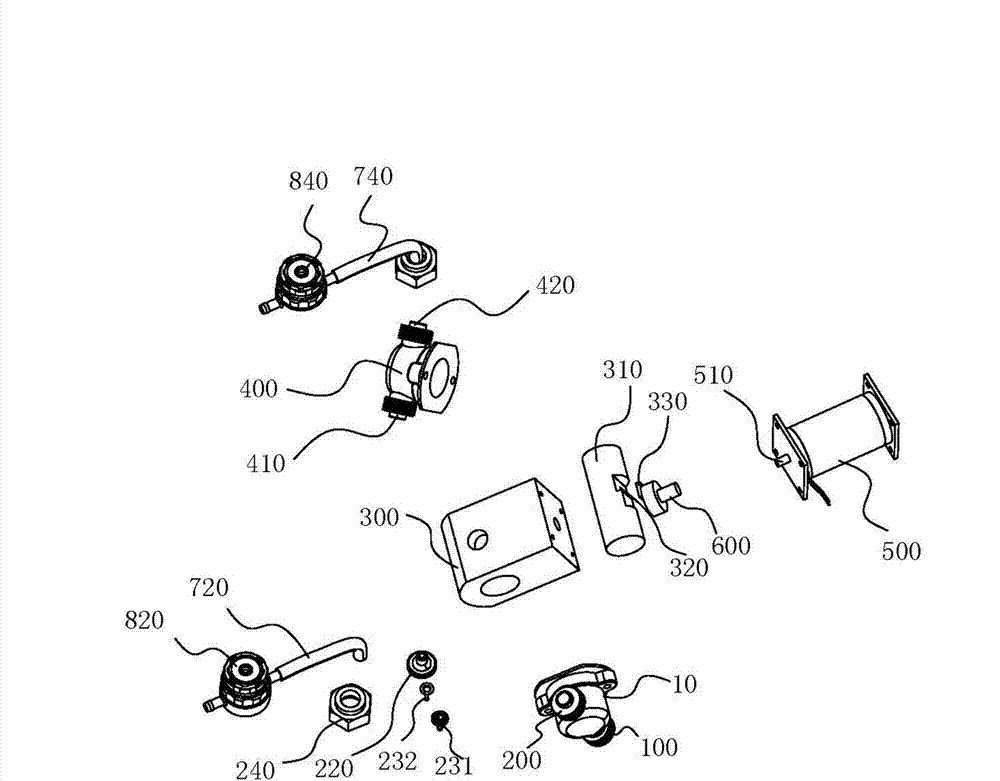

[0063] A balanced pump such as Figure 1 to Figure 5As shown, a pump body 1 , a driving motor 500 , a transmission device, a first connecting pipe 720 , a second connecting pipe 740 , a first back pressure valve 820 and a second back pressure valve 840 are provided. In order to achieve better positioning, a frame can also be provided, and the motor 500 can be installed on the frame.

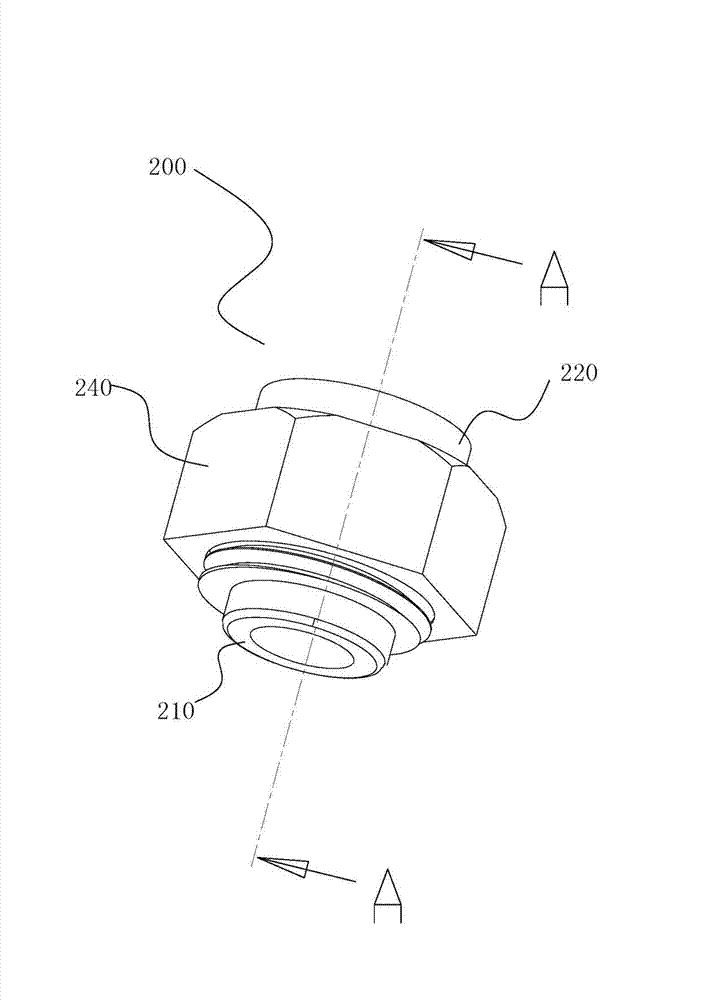

[0064] The pump body 1 is provided with a first end 10 , a pump chamber 300 , a ceramic piston 310 and a second end 400 .

[0065] The ceramic piston 310 is gap-fitted and movably arranged in the pump chamber 300 . The ceramic piston 310 is connected to one end of the transmission device, and the other end of the transmission device is connected to the motor shaft 510 of the motor 500 .

[0066] Specifically, the transmission device is set as an eccentric shaft 600, the ceramic piston 310 is provided with a groove 320, and a slider 330 is installed in the groove 320, one end of the eccentric sha...

Embodiment 2

[0100] A balance pump, the other structures are the same as in Embodiment 1, the difference is that: the first end 10 and the second end 400 have the same specifications and dimensions, the first joint 100, the second joint 200, the third joint 410, the fourth joint The 420 has the same specification dimensions.

[0101] Since the first end 10 and the second end 400 of the balance pump have the same specification and size, and the first joint 100 , the second joint 200 , the third joint 410 and the fourth joint 420 with the same specification are used.

[0102] Therefore, in one cycle, the amount of waste liquid F4 that flows out from the outlet of the fourth joint 420 is equal to the amount of fresh liquid X2 that flows out from the outlet of the second joint 200, thereby ensuring that the fresh liquid in and out of the dialyzer is equal to the amount of fresh liquid that flows out of the dialyzer in one cycle. Equal amount of waste liquid.

Embodiment 3

[0104] Other structures of a balanced pump are the same as those in Embodiment 1 or 2, except that the pump body adopts a diaphragm type balanced pump. The structure of the diaphragm balance pump is common knowledge in the art, and will not be repeated here.

[0105] Since the output end of the balance pump is provided with a back pressure valve, the conduction pressure of the one-way valve is raised, and the backflow phenomenon of the one-way valve caused by the pressure change at the outlet of the balance pump is avoided, so that the flow balance can be precisely controlled. And the setting of the back pressure valve, although the outlet pressure of the balance pump exists, can avoid the large pulsation phenomenon when the liquid flows in the whole device, and the liquid flows through the dialyzer more gently, thereby ensuring the effect of dialysis treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com