Automated ramp device

A technology of ramps and pipe grooves, applied in the field of automated ramp equipment, can solve problems such as poor environmental conditions, high work intensity, and many operational errors, and achieve the effects of saving labor resources, improving work efficiency, and expanding the scope of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

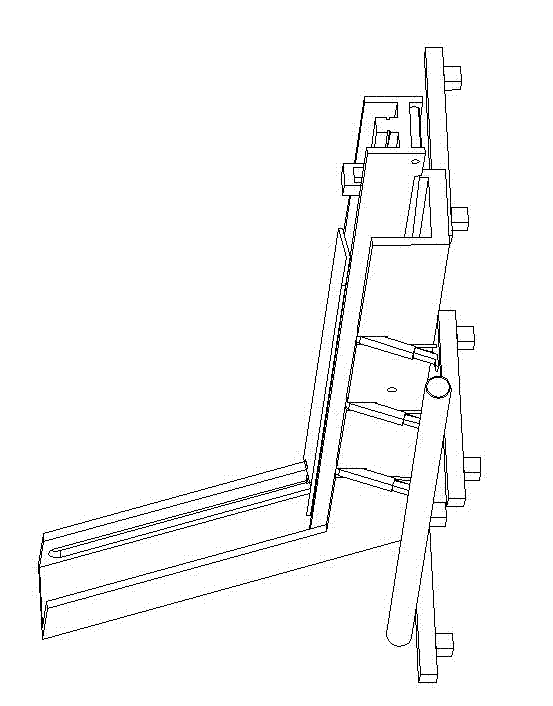

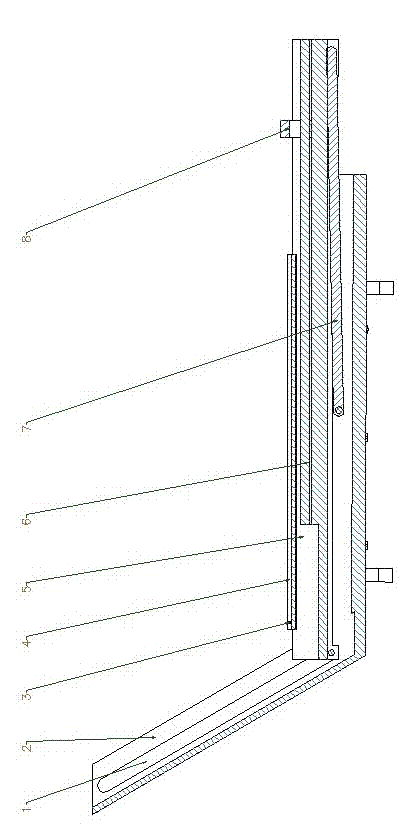

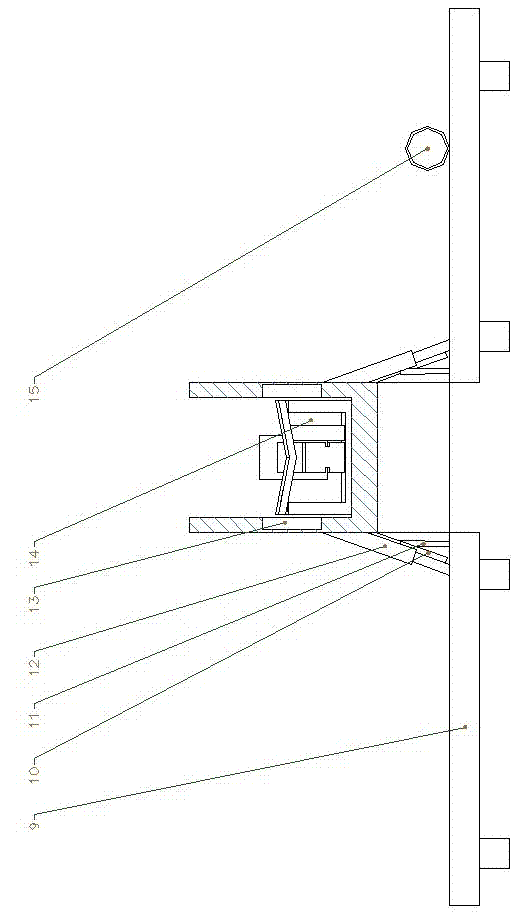

[0018] Such as figure 1 , 2 , shown in 3, a kind of automatic ramp device, comprises frame 9, ramp 2, lifting mechanism 5, lifting arm 7, pipe groove 4, tubing pushing mechanism 8, hydraulic arm 12, hydraulic arm telescopic hydraulic cylinder 10 , The hydraulic arm lifts the hydraulic cylinder 11 and the pipe groove lifts the hydraulic cylinder 14.

[0019] Ramp 2 consists of a horizontal section and an inclined section installed obliquely to the ground. The ramp 2 is installed on the frame 9, and three identical hydraulic arms 12 are respectively arranged on both sides of the horizontal section of the ramp 2, and a hydraulic arm telescopic hydraulic cylinder 10 and a hydraulic arm lifting hydraulic cylinder 11 are installed on each hydraulic arm 12. The telescopic hydraulic cylinder 10 of the hydraulic arm is used to control the expansion and contraction of the arm to determine the length of the arm. The hydraulic arm lifts the hydraulic cylinder 11, and the lifting of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com