Horizontal joint of L-shaped shear wall

A technology of horizontal connection and shear wall, applied in the direction of walls, building components, buildings, etc., can solve problems such as limited capacity, and achieve the effects of low cost, strong ability to withstand external forces, and simple node structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

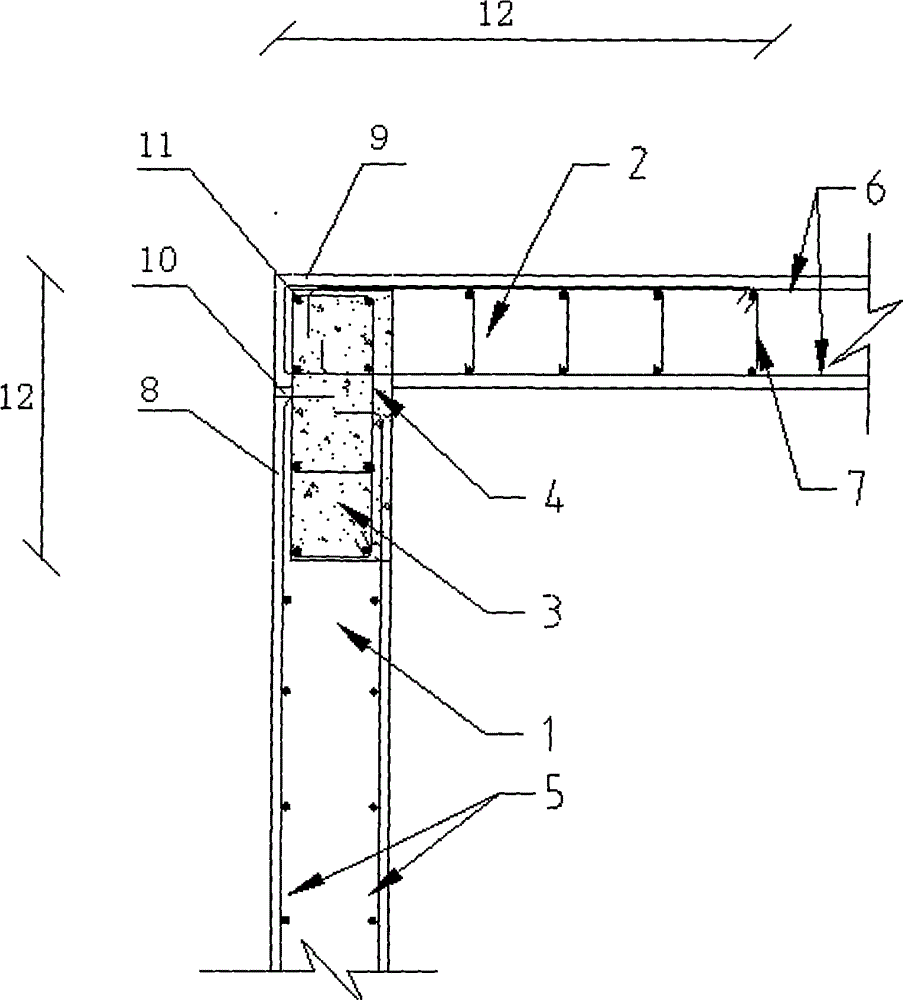

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] The present invention includes a first prefabricated shear wall 1 and a second prefabricated shear wall 2. The two prefabricated shear walls have a joint 10 of 15mm, and both have notches, and the two notches are cast-in-place concrete 3 , the first hidden column stirrup 4 at the cast-in-place notch is placed after the two prefabricated wallboards are assembled. The first prefabricated shear wall 1 has a 30 mm thick straight section thin arm 8 and a first horizontal steel bar 5, the straight section thin arm 8 acts as a formwork, and the first horizontal steel bar 5 extends to the edge of the straight section thin arm 8 for bending, The straight length after bending is not less than 10d (d is the diameter of the horizontal steel bar).

[0014] The second prefabricated shear wall 2 has a 30mm thick L-shaped thin arm 9, a second horizontal steel bar 6 and a second con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com