Coal tar hydrogenation method

A process method, coal tar technology, which is applied in the field of prolonging the life of coal tar hydrogenation catalysts, can solve the problems of difficult processing, etc., and achieve the effects of difficult processing, prolonging the operation cycle, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Coal tar was processed on a continuous hydrogenation test device equipped with 0.5L industrial heavy oil hydrogenation catalyst. The catalyst used is the RHT series hydrogenation catalyst developed by the Beijing Institute of Petroleum Science. The coal tar raw material used in the test comes from the medium-temperature coal tar in northern Shaanxi. Its properties are shown in Table 1. The catalyst type, physical and chemical properties and the loading amount of each catalyst are shown in Table 1. 2. This device adopts the pre-vulcanization technology in the wet in-situ device. The specific vulcanization operating conditions and vulcanization temperature rise are shown in Table 3 and Table 4. The device is at an airspeed of 0.5h -1 , the reaction pressure is 14MPa, the hydrogen oil ratio is 1200:1, the protective agent bed temperature is 300°C, the metal removal agent bed temperature is 350°C, the desulfurization agent bed temperature is 360°C, and the denitrification ...

Embodiment 2

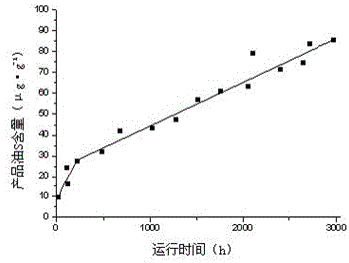

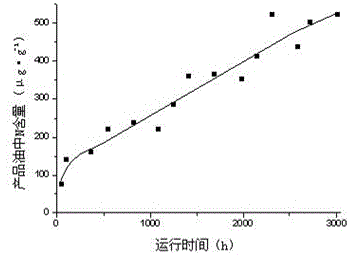

[0037] Raw materials, catalyst and process conditions are consistent with embodiment 1, but continuously inject sulfidation agent CS to the catalyst bed of the device during operation 2 , control the hydrogen sulfide concentration in the circulating hydrogen to 0.07%. The change curve of sulfur and nitrogen content in the product oil with time is shown in image 3 , 4 .

[0038] Depend on image 3 , 4 It can be seen that, and compared with the situation of Example 1 (no sulfur supplementation), sulfur supplementation is continuously added to the reactor during the hydrogenation process, and the hydrogenation product will maintain a high desulfurization rate and denitrification rate within 3000 hours. Moreover, with the prolongation of time, the sulfur and nitrogen content in the product oil fluctuated less, indicating that sulfur supplementation played a great role in maintaining the activity of the catalyst.

Embodiment 3

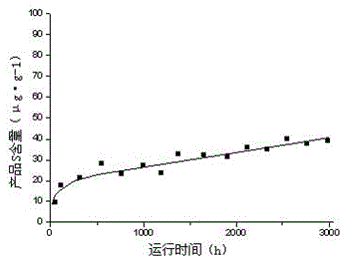

[0040] Coal tar is processed on a continuous hydrogenation test device equipped with a 0.5L industrial heavy oil hydrogenation catalyst. The catalyst used comes from the FZC series hydrogenation catalyst developed by Fushun Research Institute of Catalysts. The raw material of coal tar for the test comes from medium-temperature coal tar in northern Shaanxi. See Table 1 for its properties, and Table 5 for the model and physical and chemical properties of the catalyst and the loading amount of each catalyst. The device is at an airspeed of 0.5h -1 , reaction pressure 14.5MPa, hydrogen-oil ratio 1000:1, protective agent bed temperature 290°C, demetallization agent bed temperature 350°C, desulfurization agent bed temperature 360°C, denitrification agent bed temperature 370°C under the conditions of continuous After running for 3000 hours, the change curve of sulfur and nitrogen content in product oil with time is shown in Figure 5 , 6 .

[0041]

[0042] from Figure 5 , 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com