Device and method for tracing and checking shallow color code mark of drum type multicolor rotogravure press

A technology of tracking detection and gravure printing machine, which is applied to the general parts of printing machinery, printing presses, printing and other directions, can solve the problems of difficult detection and tracking and identification of light-colored color mark marks in a roll-type multi-color gravure printing machine, and achieves technical The scheme is simple and reliable, easy to implement, and has strong applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] 1. The working principle and problems of the existing registration system

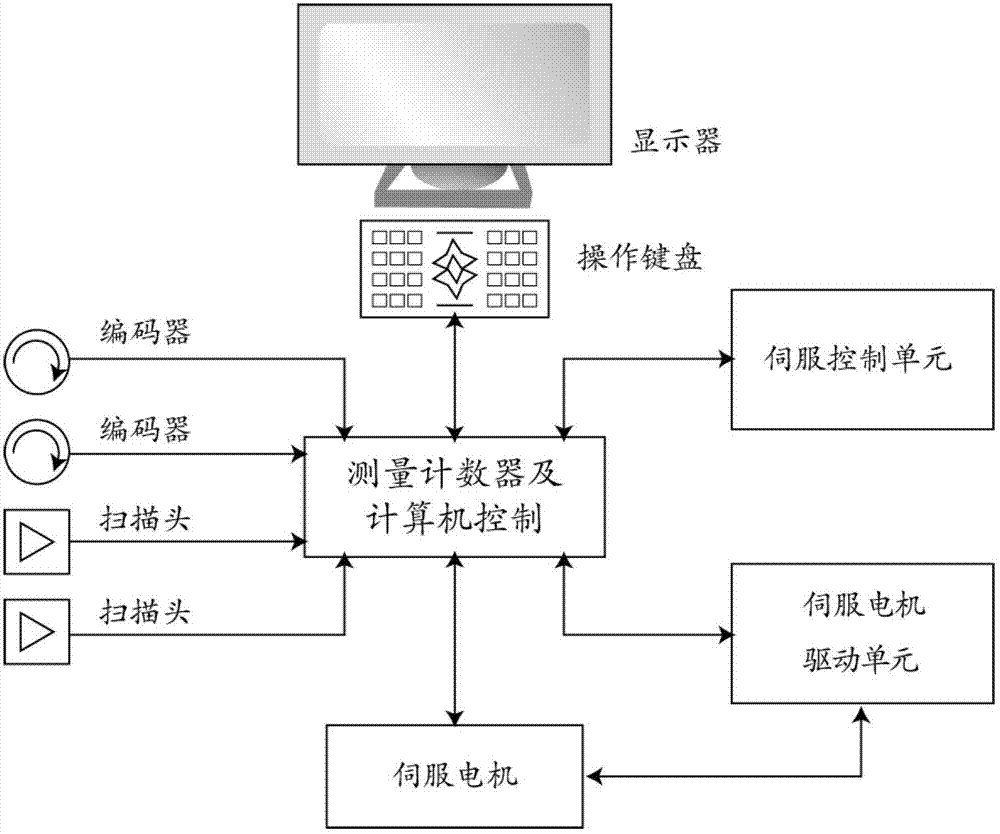

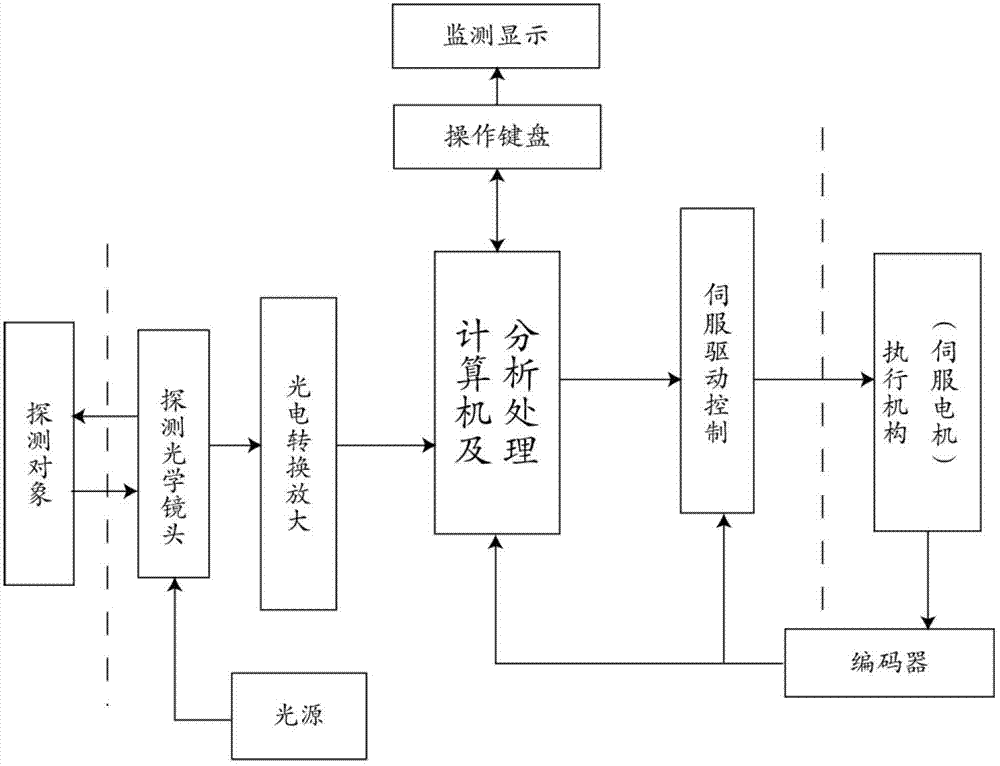

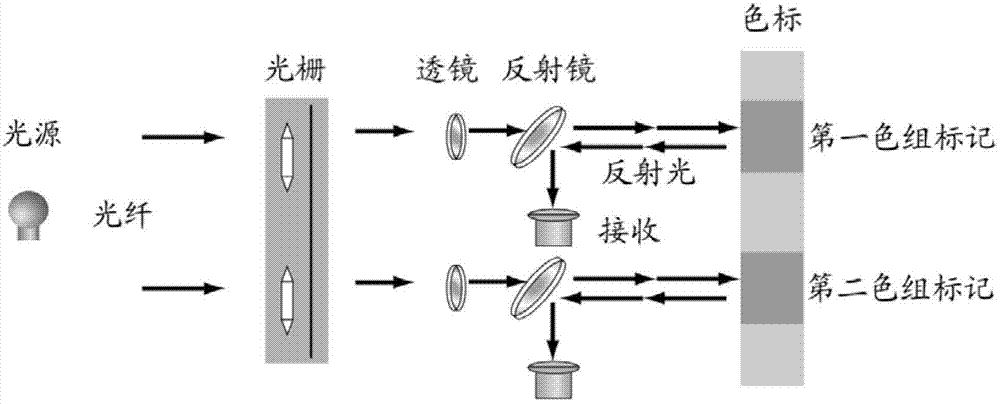

[0035] figure 1 and figure 2 A schematic diagram of the structure composition and working principle of the QuadTech registration system commonly configured in multi-color gravure printing machines is given. It can be seen that after the detection object is scanned by the scanning head, it is transmitted to the photoelectric conversion element respectively, and the optical signal is converted into an electrical signal by the photoelectric conversion element, which is amplified and shaped and then sent to the computer and the analysis and processing unit. After the computer receives the detected signal, it analyzes, compares and calculates the relevant parameters (such as graphics, size, color scales of various colors, distances between identification marks, etc.) and information of the detected object identification marks preset in the memory. Processing, input the digital control signal to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com