Mold capable of realizing delayed ejection and accelerated ejection simultaneously

A technology of accelerating top and mold, applied in the field of mold structure combining slow top and accelerating top, and ejecting structure, it can solve the problems of complicated interaction and connection, unable to realize slow top, complicated action process, etc., and achieve low processing and manufacturing cost. , improve the accuracy and increase the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

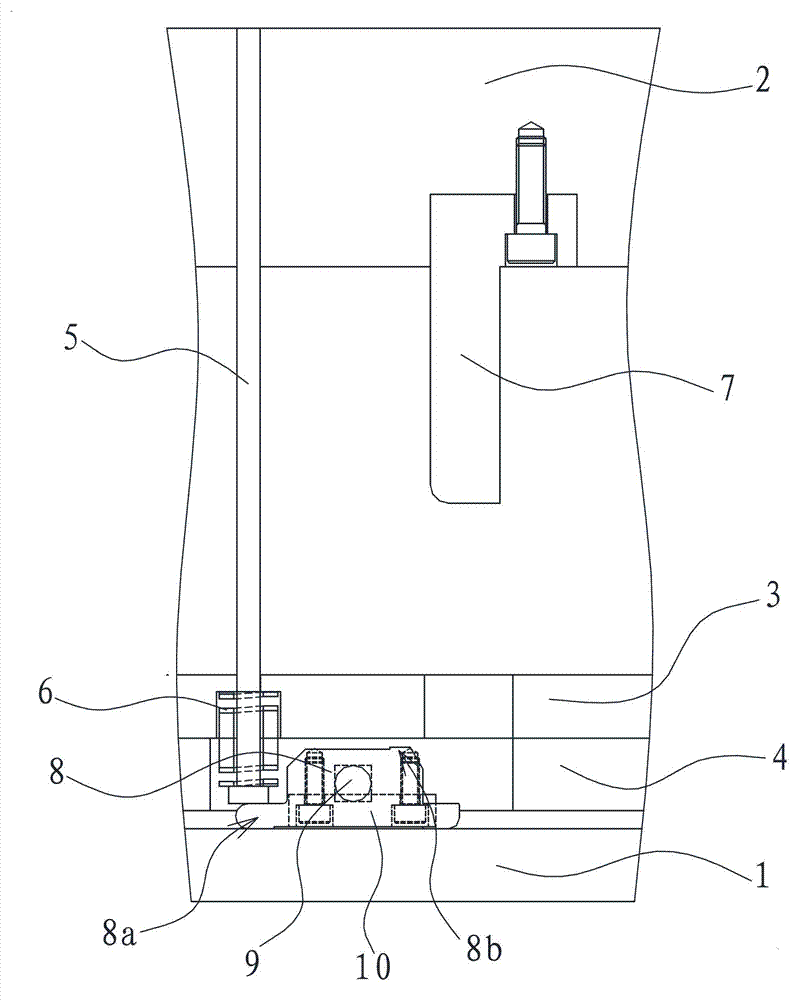

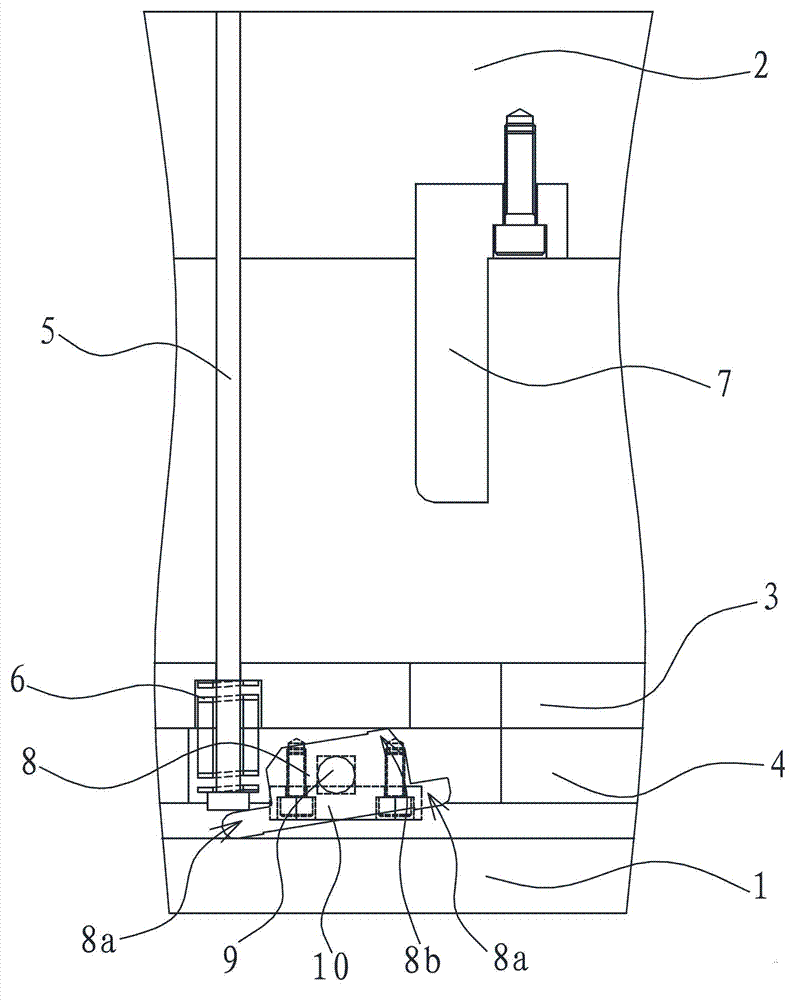

Image

Examples

Embodiment 2

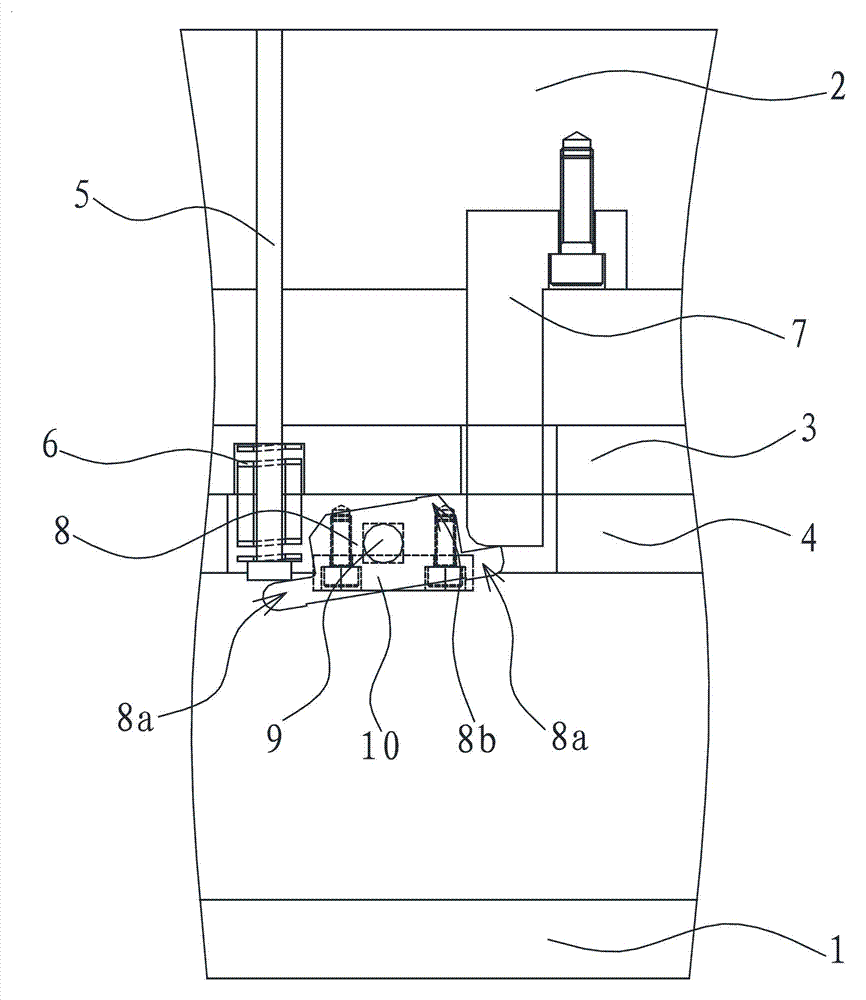

[0032] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that:

[0033] The acceleration gear lever is integrally fixed on one side swing end 8a of the acceleration top block 8, and the acceleration gear lever extends vertically upward. When the acceleration top block 8 abuts against the initial position of the movable mold fixed plate 1, the top of the acceleration stop bar and the movable template 2 are separated by a certain space distance, and because the area of the movable template 2 is relatively large, the acceleration top block 8 rises to When in a proper position, the acceleration stop lever on one side of the swing end 8a can be in contact with the bottom surface of the movable template 2, and then the acceleration top action can be realized through the seesaw principle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com