Socket pipe processing device and manufacturing method for socket pipe

A manufacturing method and a technology of a processing device, which are applied in the manufacture of socket tubes, processing devices for socket tubes and the field of socket tube manufacturing, can solve problems such as uneven thickness of socket tubes and difficulty in maintaining consistent strength, and achieve long-term Reliable operation, small concentricity deviation, and the effect of preventing deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

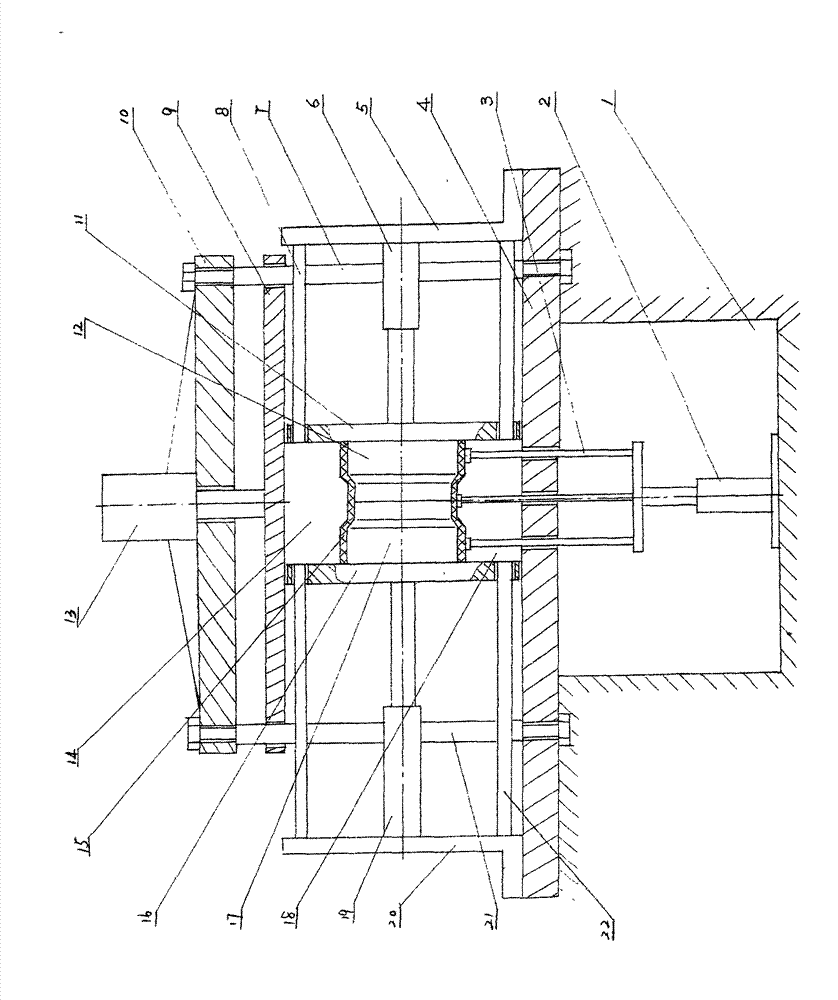

[0007] Below in conjunction with the accompanying drawings, the present invention will be further described by taking the manufacture of double-ended socket tubes as an example:

[0008] See attached figure 1 , the whole device is fixed on the ground through the workbench 4, and the ground is provided with a pit 1. The bottom surface of the pit 1 is fixed with a top piece oil cylinder 2, and the top piece device 3 arranged in the lower mold 18 passes through the workbench 4 and conflicts with the top plate 23 on the top piece oil cylinder 2; the right side of the workbench 4 is fixed with a right right-angle bracket 5 , the left side is fixed with a left right-angle support 20, and the front and rear of the four-corner upper side between the left right-angle support 20 and the right right-angle support 5 are fixed with an upper side mold core slide bar 8, and the front and rear of the lower side are fixed with a lower side mold core slide bar 22 , the upper mold core slide ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com