Novel hydraulic gate type movable plate shearing machine

A mobile shearing machine, hydraulic technology, applied in the direction of shearing machine equipment, shearing device, metal processing equipment, etc. The effect of increased rigidity and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

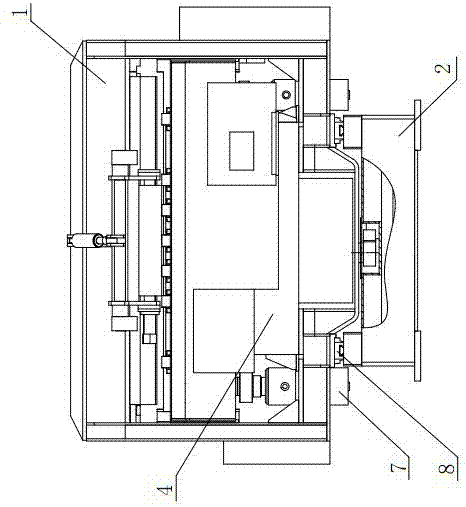

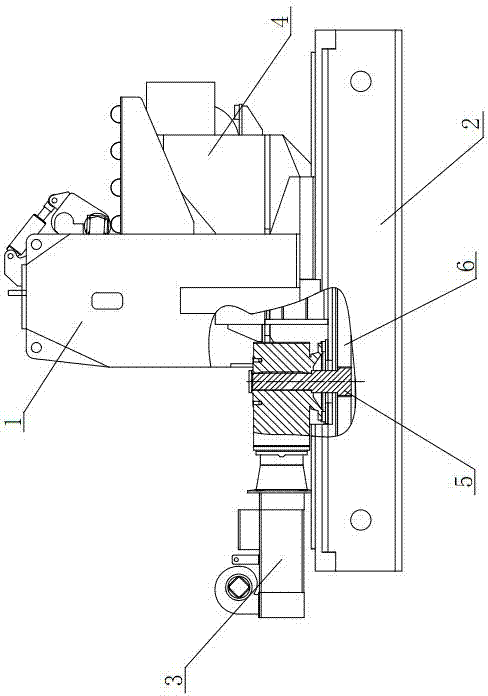

[0015] From figure 1 It is a schematic diagram of the main structure of the present invention, figure 2 It can be seen from the left view that the present invention includes a moving part 1, a base part 2, a power part 3, a hydraulic part 4 and corresponding control parts, and the control part is a numerical control device. A power part 3 is installed on the rear side of the moving part 1, and the power part 3 provides power for the moving part, and the power part 3 is placed on the moving part 1 and moves together therewith. The power part 3 includes a servo motor, a speed reducer, and a gear shaft 5, and the servo motor is connected to a single gear shaft 5 through a speed reducer. The moving part 1 mainly has a frame, an upper and lower knife rest, a pressing device, a shearing cylinder 7, a gap adjustment device, a shearing angle adjustment device, a plate tail pinch and a material receiving device, which are used to move and cut together with the sheet. Then on the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com