Inner drilling device for processing thin-wall tube member

A technology for drilling devices and workpieces, which is applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc., and can solve the deformation of the inner cylinder of thin-walled workpieces and the inefficiency of inner drilling processing, etc. problem, to achieve the effects of simple process, avoiding deformation of the inner cylinder, and high hole forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

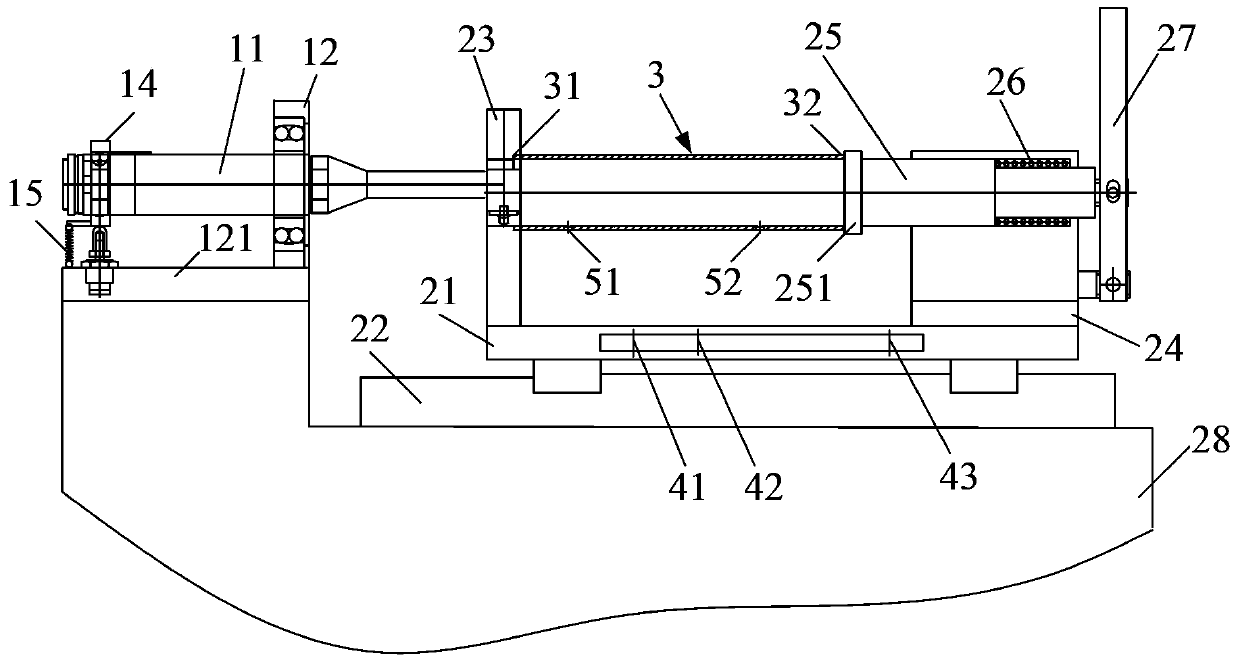

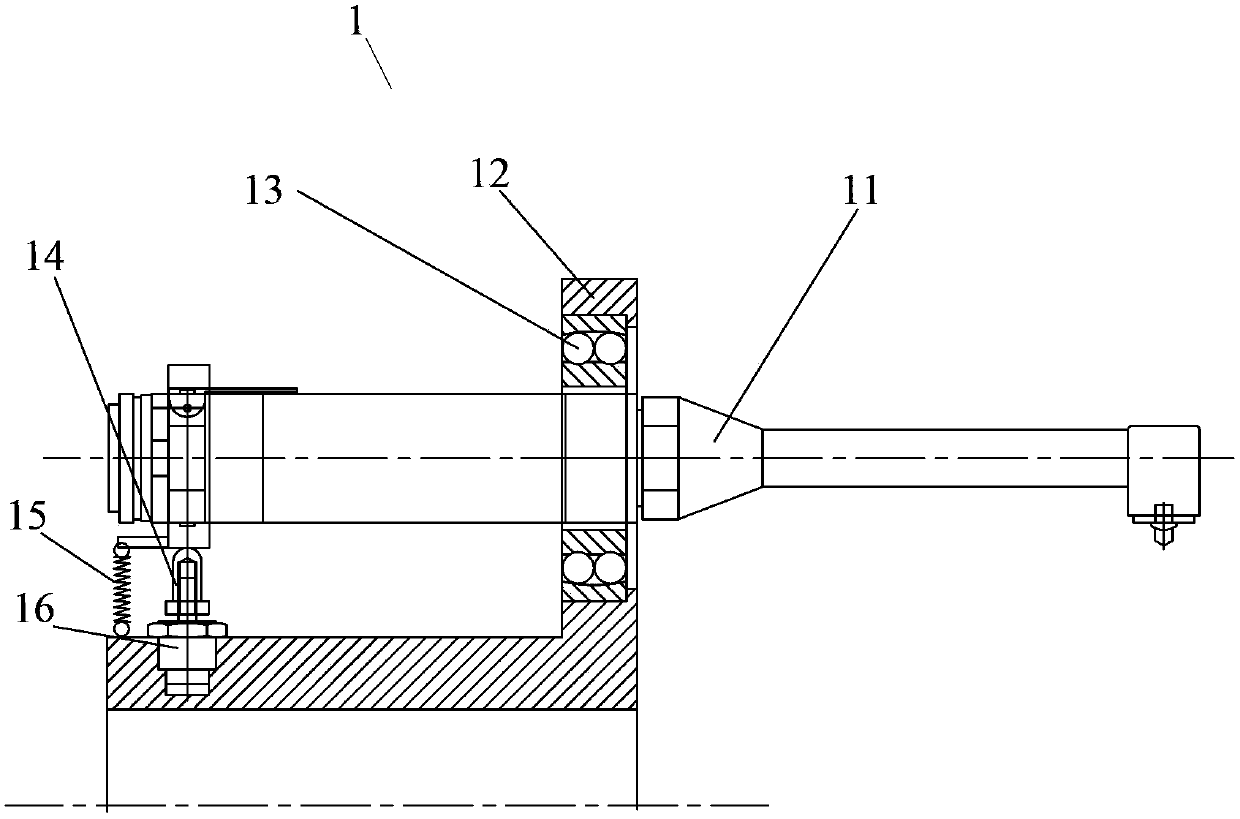

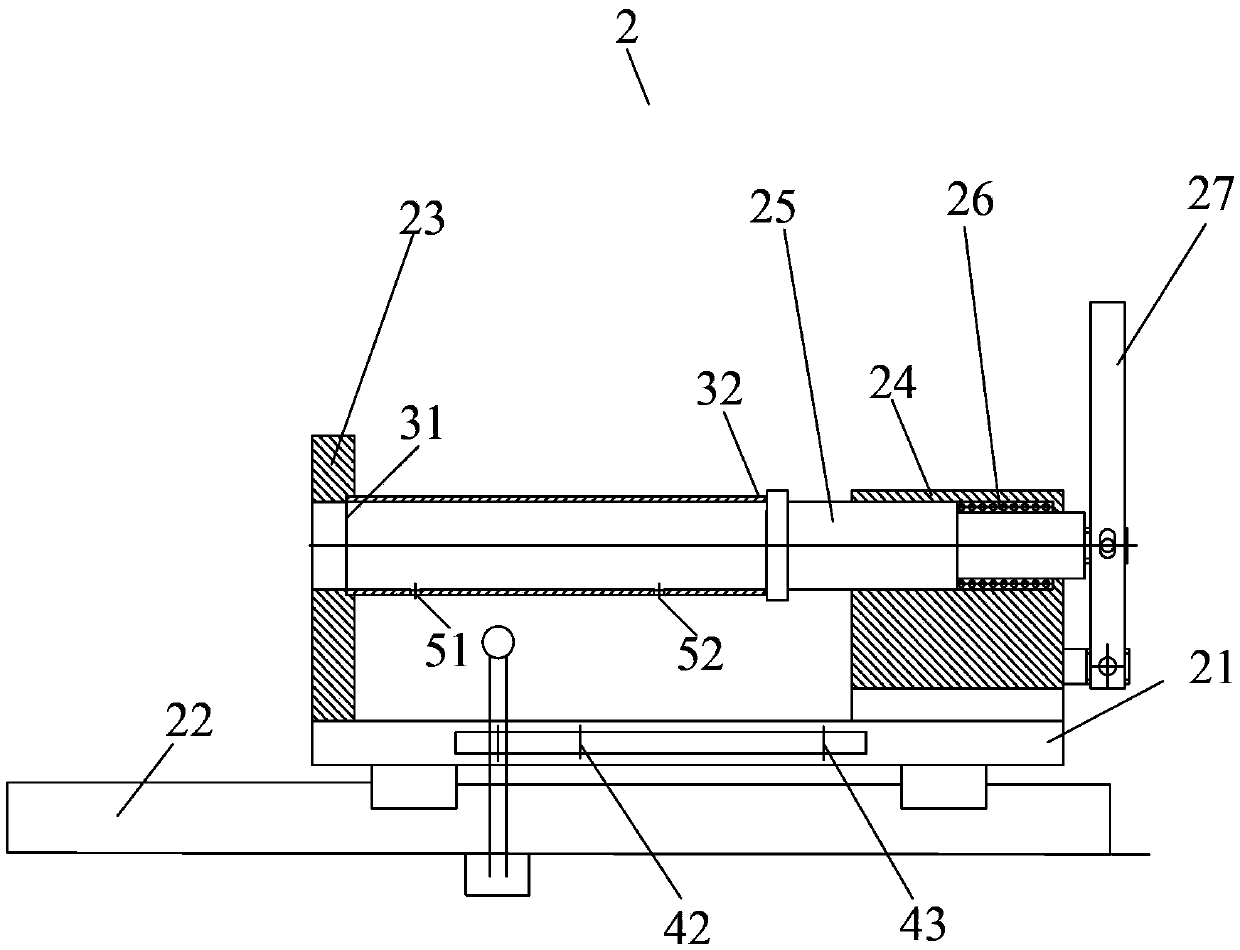

[0034] Such as Figure 1 to Figure 4 As shown, an inner drilling device for processing thin-walled cylindrical parts provided by the present invention is mainly composed of a feed device 1 for a pneumatic angle drill and a slide device 2 for clamping a workpiece 3 (hereinafter referred to as a workpiece). Partial composition. The installation of the pneumatic angular drill 11 is to install the pneumatic angular drill 11 on the self-aligning bearing seat 12 with the self-aligning bearing 13 in the self-aligning bearing seat 12 as the lever fulcrum. Cylinder 14 moves up and down to realize drill bit drilling. The threaded pneumatic cylinder and the pneumatic angular drill in this embodiment can be realized by respectively using the threaded pneumatic cylinder and the pneumatic angular drill known in the prior art, so this part will not be repeated here.

[0035] Pneumatic angular drill 11 is fixed on the self-aligning bearing block 12, and comprises a special shaped drill bit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com