Method for producing collar

A collar and wire technology, applied in the direction of manufacturing tools, heating/cooling equipment, forging/pressing/hammer devices, etc., can solve problems such as interruption, save time and cost, save setting time, and simplify supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

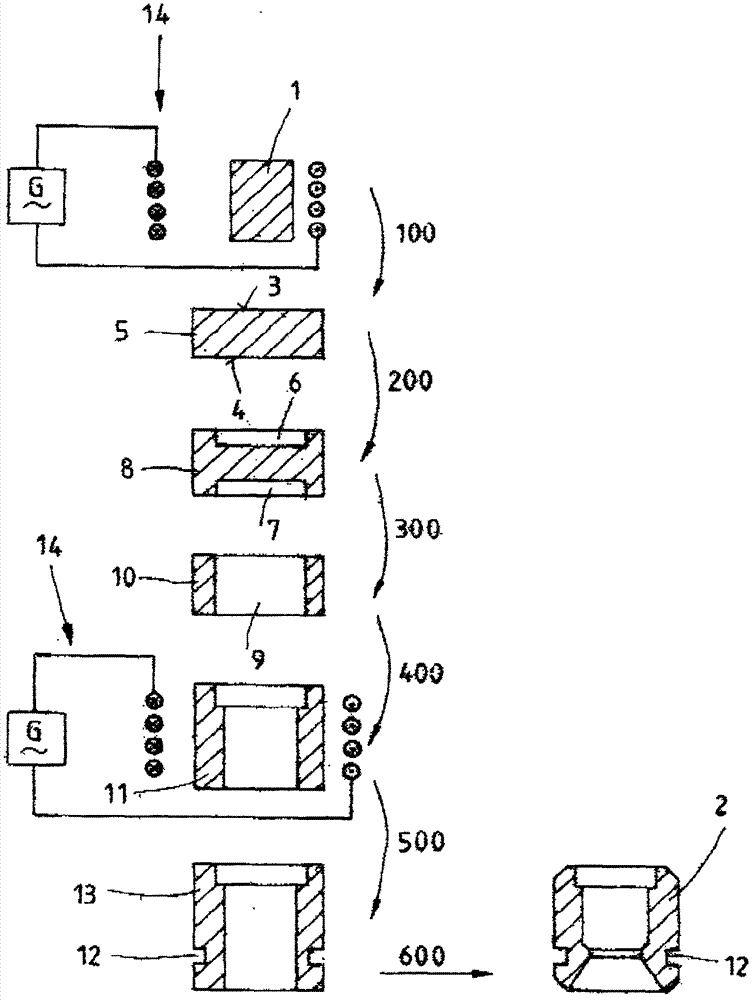

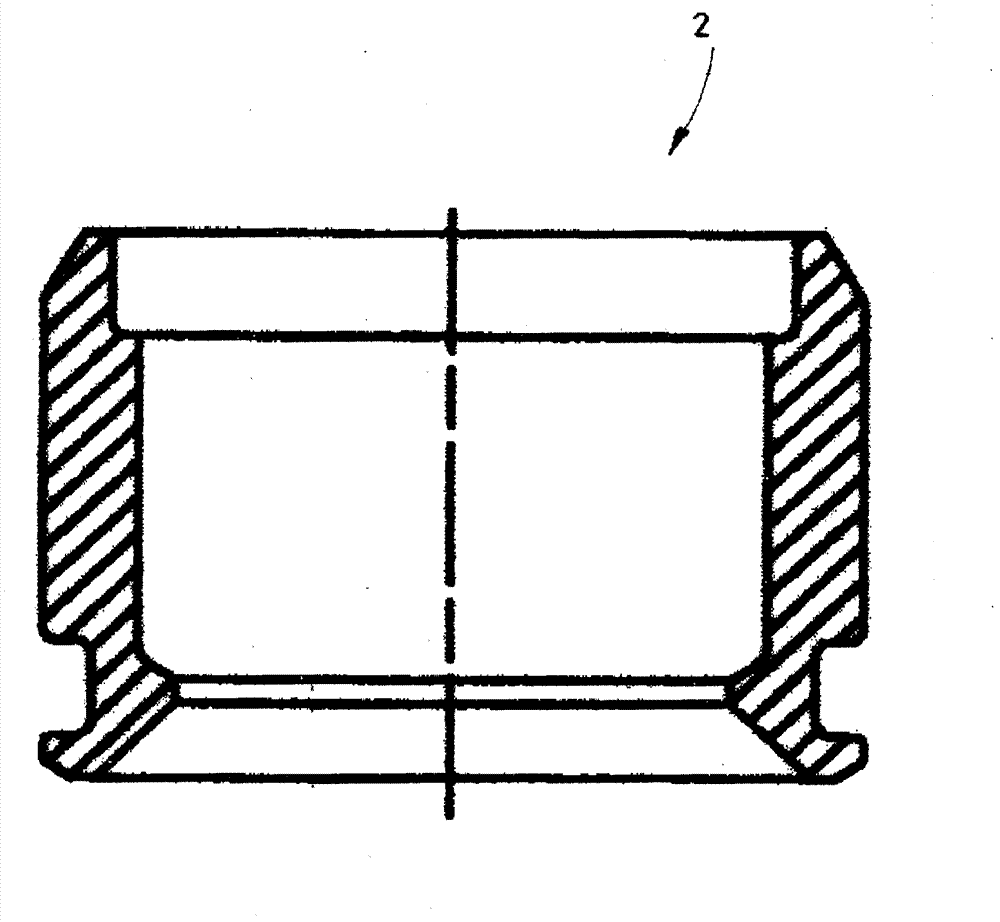

[0048]The method according to the invention relates to the manufacture of collars, ie annular collars, for example in the form of collars with flanges. The collar 2 that can be manufactured according to the method of the present invention is in figure 2 shown in . figure 2 The final design is shown but not to scale.

[0049] To manufacture follow figure 2 The final sleeve profile of the sleeve ring 2 illustrated in figure 2 The process schematically illustrated in Fig.

[0050] The starting point of the process is Blank 1. The blank 1 is prepared by separating a certain wire length from a coiled wire which is not in the figure 1 is further shown in . Separation of the coiled wire to prepare the billet 1 can be done eg by shearing.

[0051] Immediately thereafter, the blank 1 is flattened in a molding step 100 , ie the flat front surfaces 3 and 4 of the blank are formed. With this flattening step by molding, an intermediate product 5 is obtained.

[0052] Thereafte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com