Bag type dust collector modified from electric dust collector

A technology of bag filter and electrostatic precipitator, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as unsatisfactory economic benefits, equipment scrapping, material loss, etc., and achieve material saving and maintenance Convenience and the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

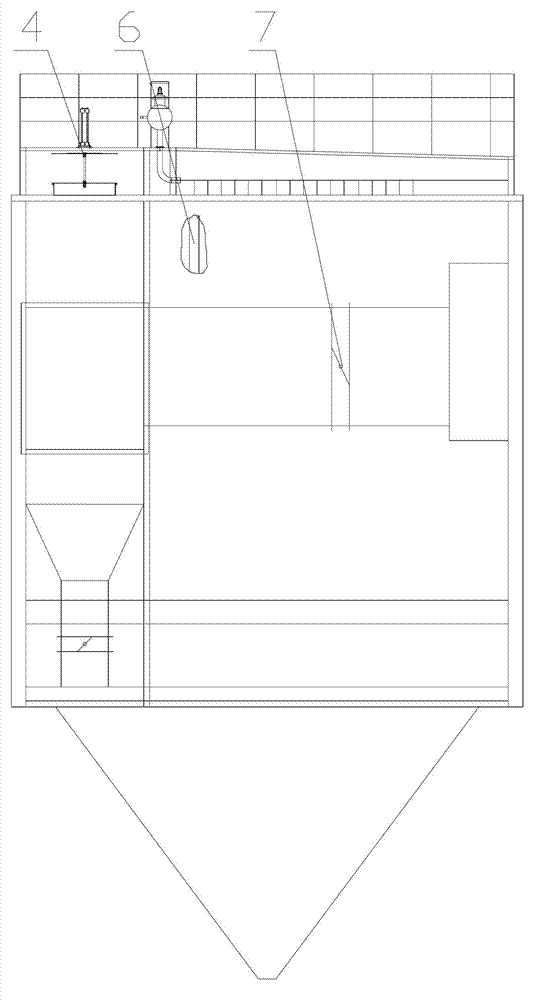

[0016] Such as figure 1 and figure 2 As shown, the bag filter modified by the electrostatic precipitator includes a bracket, a box body 1, an injection device 2, a filter bag assembly 6 and a control device, and a number of filter bag assemblies 6 are installed in the box body 1, and the box body The two ends of 1 are respectively provided with an air inlet and an air outlet, and the filter bag assembly 6 is composed of a filter bag and a bag cage, and a deflector is arranged between the filter bags. The air inlet channel in the box body 1 is provided with a pneumatic butterfly valve 7 , the air inlet channel switching mechanism 4 is arranged on the box body 1 , and the ash hopper 5 is arranged below the box body 1 . The blowing device 2 is arranged on the top of the box body 1, and the blowing device 2 is connected with an air compression device through a pipeline, and the air compression device is connected with the pneumatic butterfly valve 7.

[0017] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com