Retainer for adjustment device of friction clutch, and friction clutch

A friction clutch, compensation and adjustment technology, applied in the direction of friction clutch, clutch, mechanical drive clutch, etc., can solve the problems of friction torque reduction and no longer being able to transmit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

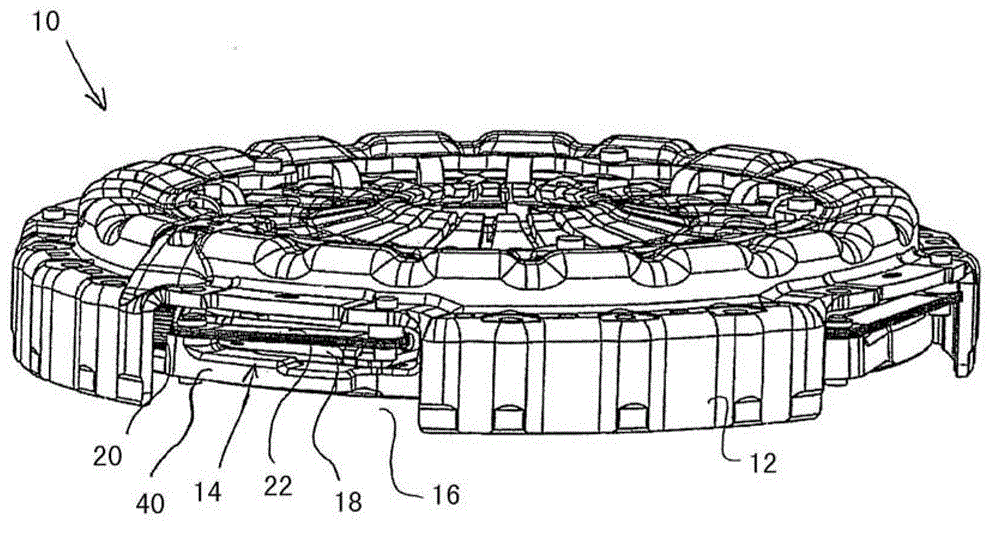

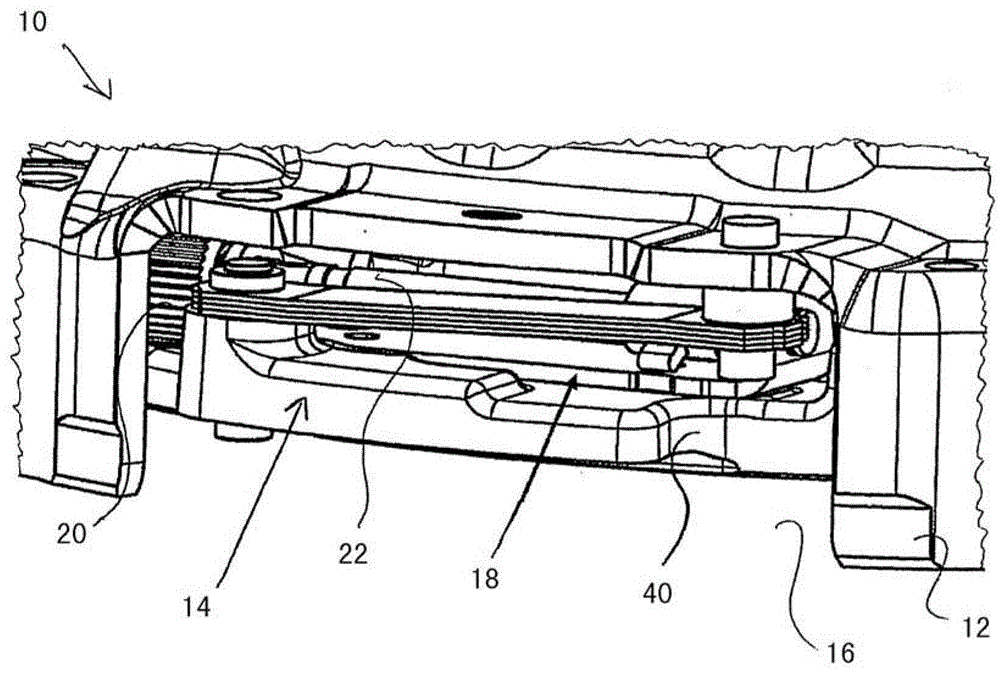

[0029] figure 1 and figure 2 The friction clutch 10 shown in has a clutch housing 12 which has a service opening 16 in the region of an adjusting unit 14 for wear-induced maintenance of a pressure plate 40 movable relative to a counter pressure plate. The mis-spacing is compensated to squeeze the clutch plate between the counter plate and the pressure plate 40 . Visible through the service opening 16 is a cage 18 which carries a threaded spindle 22 connected to a pinion 20 .

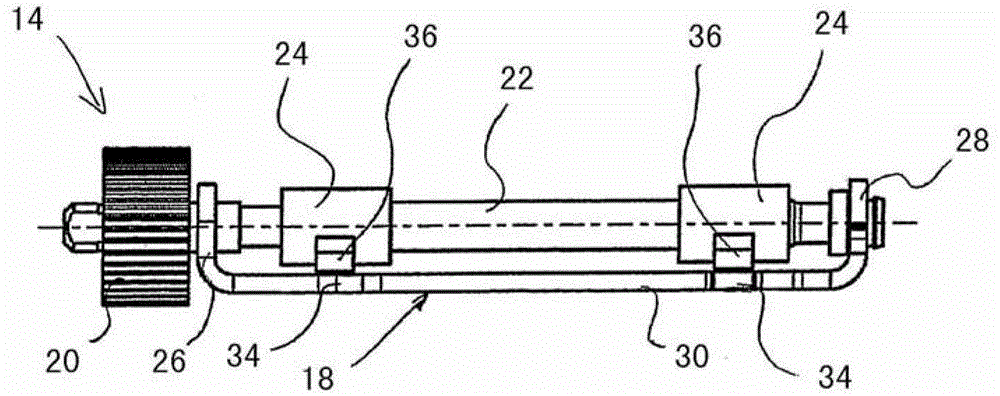

[0030] Such as image 3 and 4 As shown, a screw nut 24 is screwed on the lead screw 22, and the lead screw nut 24 can move from the original position (left position) without friction lining wear in the axial direction along the lead screw 22 to the friction End position with fully worn lining (right position). The cage 18 has a first retaining arm 26 and a second retaining arm 28 to support the lead screw 22 . The first retaining arm 26 and the second retaining arm 28 are connected to each other i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com