Yarn guide rail unit, flat knitting machine, and method of equipping the flat knitting machine

A technology of a flat knitting machine and a yarn guide, which is applied in the field of yarn guides, can solve the problems of reducing the output of knitted fabrics, increasing the cost of mechanical operation, and the fact that the track driving device of the yarn guide cannot be easily disassembled or replaced, etc. The effect of join and quick join

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

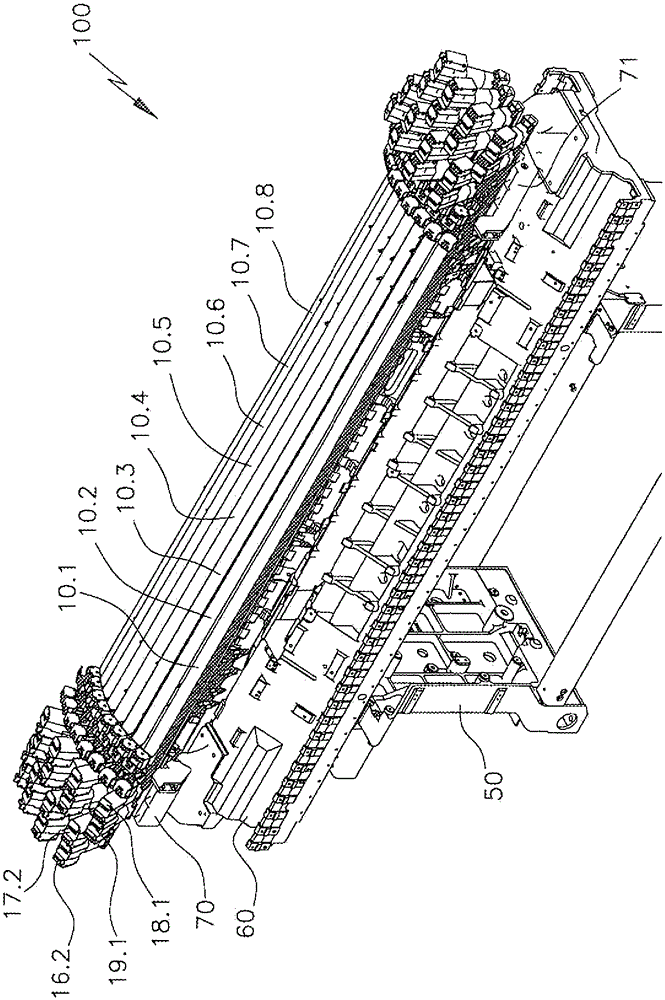

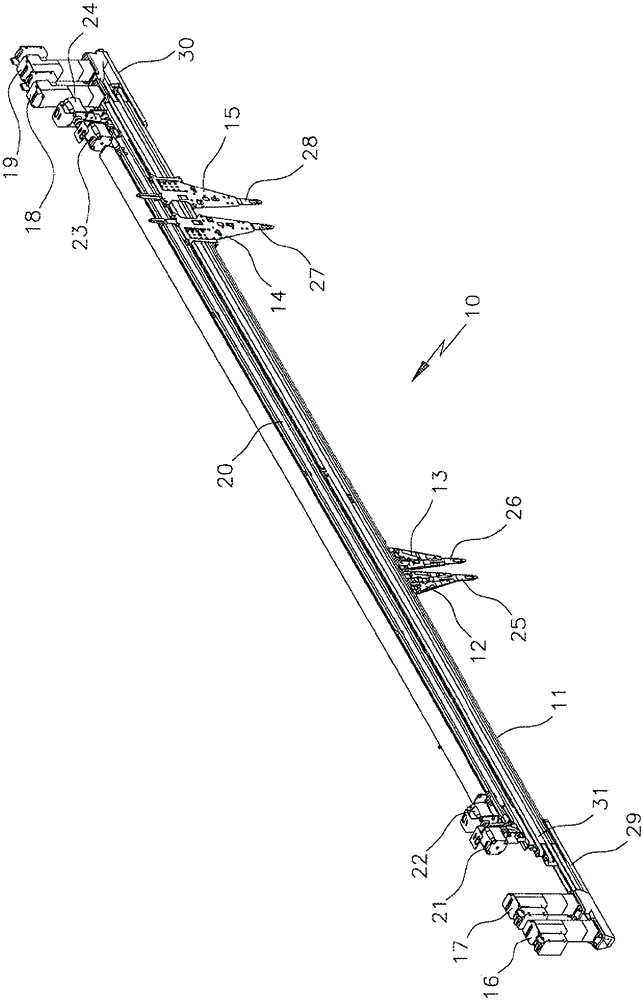

[0024] figure 1 The perspective illustration shows an individual pre-assembled thread guide rail unit 10 in a ready-to-use state, in which state the thread feeder rail unit 10 can be inserted into a flat knitting machine. The thread carrier rail unit 10 includes a thread carrier rail 11 where the thread carriers 12 - 15 are arranged movable in the longitudinal direction of the thread carrier rail 11 . The yarn guides 12-15 are so-called independently driven yarn guides. This means that each yarn guide 12-15 is associated with its own yarn guide drive. The thread guide drives 16 - 19 are each coupled to the thread guides 12 - 15 via transmission means, wherein only one transmission means 20 designed as a drive belt is provided with reference numerals in this exemplary embodiment by way of example.

[0025] Furthermore, servomotors 21 - 24 are arranged on the thread guide rail unit 10 , via which servomotors 21 - 24 the thread guide blades 25 - 28 can be moved.

[0026] Arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com