Dishwasher with comminution device

A tableware washing machine and crushing device technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, household cleaning devices, etc., can solve the problem of increasing the manufacturing cost of the tableware washing machine and increasing the risk of operation failure , Occupy manufacturing costs and other issues, to achieve the effect of cost-effective operation reliability and improve operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

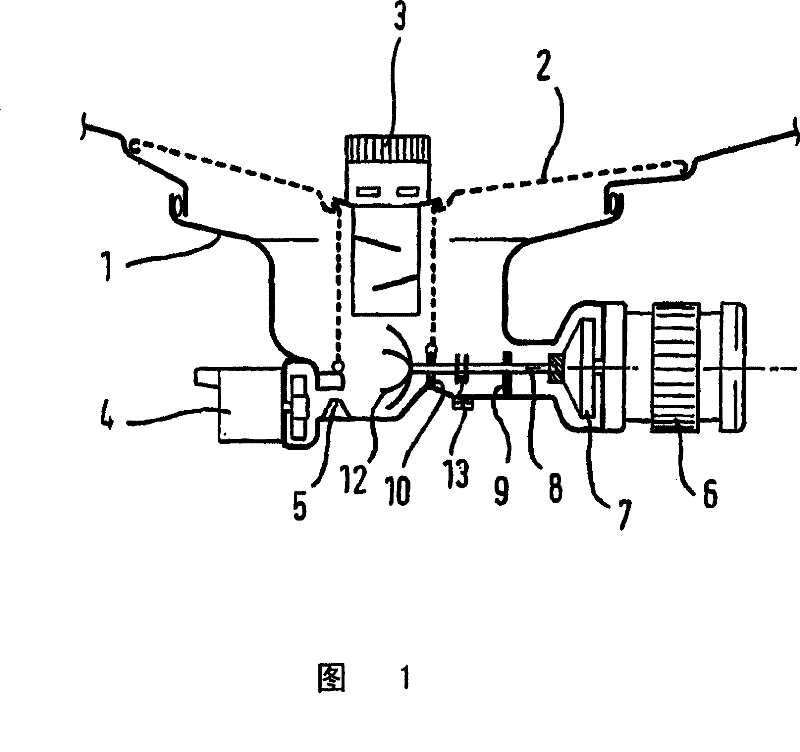

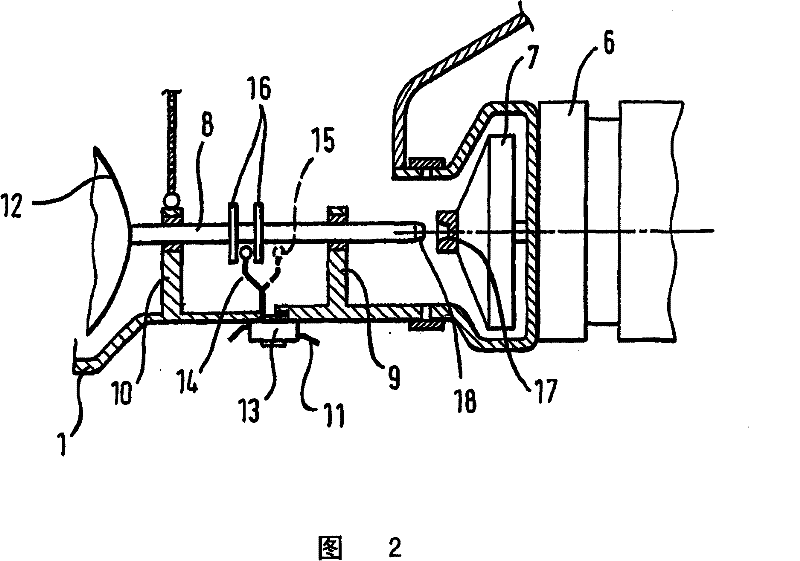

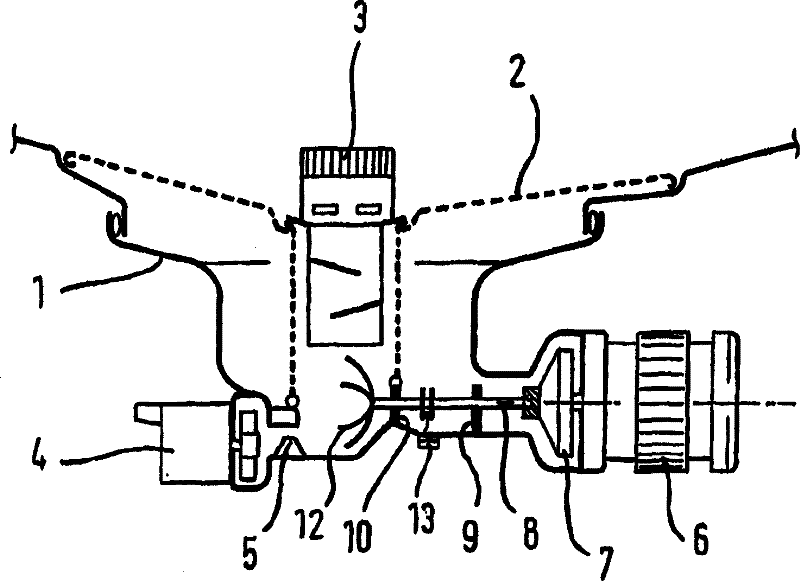

[0023] figure 1 A cross-section through the lower part of a dishwasher with a crushing device according to the invention is shown. In the lower part of the dishwasher there is a pump head 1 which closes a washing container (not completely shown) of the dishwasher downwards. In the upper part of the pump head 1 there is a sieving mechanism which essentially consists of a fine sieve 2 and a coarse sieve 3 integrated therein. During washing operation, the washing liquid passes downwards in the washing container through the sifting devices 2 and 3 and collects on the bottom plate of the pump head 1 . From there, the rinsing liquid is either pumped back into the delivery path for the rinsing liquid by the circulation pump 6 during the washing operation or is discharged from the dishwasher by means of the lye pump 4 through a pyramid 5 during the extraction operation.

[0024] In particular during the pre-rinsing phase and the cleaning process, in the region before the pyramid 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com