IPS liquid crystal display panel and method for manufacturing the same

A technology for liquid crystal display panels and manufacturing methods, which is applied in the fields of nonlinear optics, instruments, and optics, and can solve problems such as low transmittance of IPS panels, decreased pixel aperture ratio, and reduced light-transmitting area, so as to improve light leakage and enhance The effect of aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

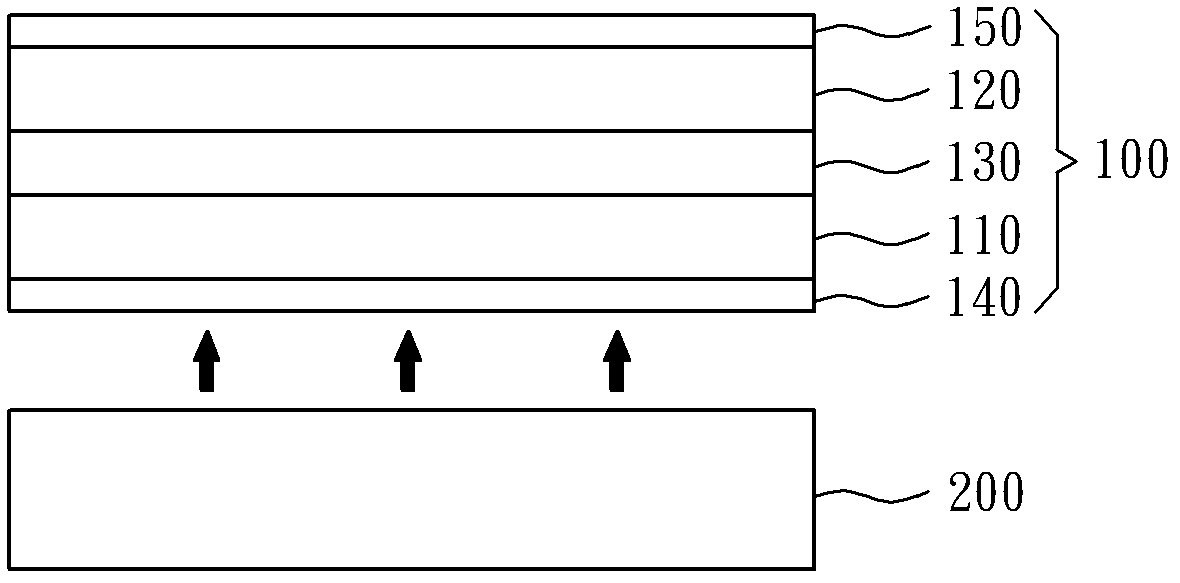

[0035] Please refer to figure 1 , which shows a schematic cross-sectional view of a display panel and a backlight module according to an embodiment of the present invention. The in-plane switching (IPS) liquid crystal display panel 100 of this embodiment can be disposed on the backlight module 200 , thus forming an IPS liquid crystal display device. The IPS liquid crystal display panel 100 may include a first substrate 110 , a second substrate 120 , a liquid crystal layer 130 , a first polarizer 140 and a second polarizer 150 . The substrate material of the first substrate 110 and the second substrate 120 can be a glass substrate or a flexible plastic substrate. In this embodiment, the first substrate 110 can be, for example, a thin film transistor (Thin Film Transistor, TFT) matrix substrate, while the second The second substrate 120 can be, for example, a color filter (Color Filter, CF) substrate. It should be noted that, in some embodiments, the color filter and the TFT m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com