Analytical method for iron ore high-temperature soft melting characteristics

A characteristic analysis and iron ore technology, which is applied in the field of iron ore high-temperature reflow characteristic analysis, can solve problems such as unanalyzable relationship, triangular cone cannot be softened, and quantitative measurement cannot be measured, so as to achieve accurate detection results and solve the problem of iron ore Difficulties in the detection of high temperature reflow characteristics, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

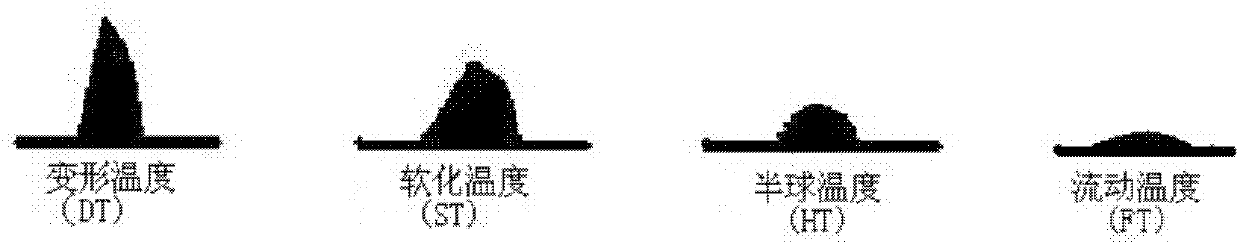

[0055] In this embodiment, the same iron ore is detected by the detection method provided by the present invention and the existing iron ore high-temperature reflow characteristic detection method, that is, the "triangular cone method", and the test results are compared and analyzed. As can be seen from Table 3, the iron ore deformation temperature DT of "triangular cone method" is closer to the iron ore reflow initiation temperature of the detection method provided by the invention, and due to the "limitation" of the "triangular cone method" test method , it can only obtain the deformation temperature DT of iron ore, but cannot measure the softening temperature ST, hemispherical temperature HT and flow temperature FT of iron ore, and this patent method can obtain complete test information (the iron involved in Table 4 For the detection data of ore, refer to the attached Figure 3-7 ), so as to fully characterize the high temperature reflow characteristics of iron ore.

[005...

Embodiment 2

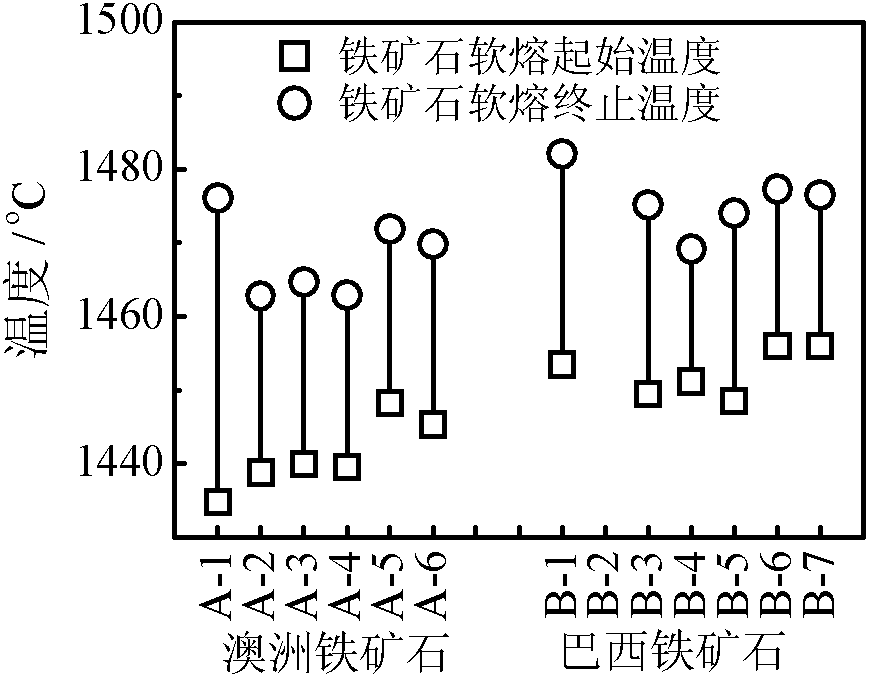

[0060] In this embodiment, 13 kinds of iron ores in total, 6 kinds of Australian ores and 7 kinds of Brazilian ores were selected respectively, and made into powdery samples with a particle size of -0.125 mm for future use. The chemical composition of iron ore is shown in Table 4, and the test conditions are shown in Table 2.

[0061] Table 4 test iron ore chemical composition (mass percentage)

[0062]

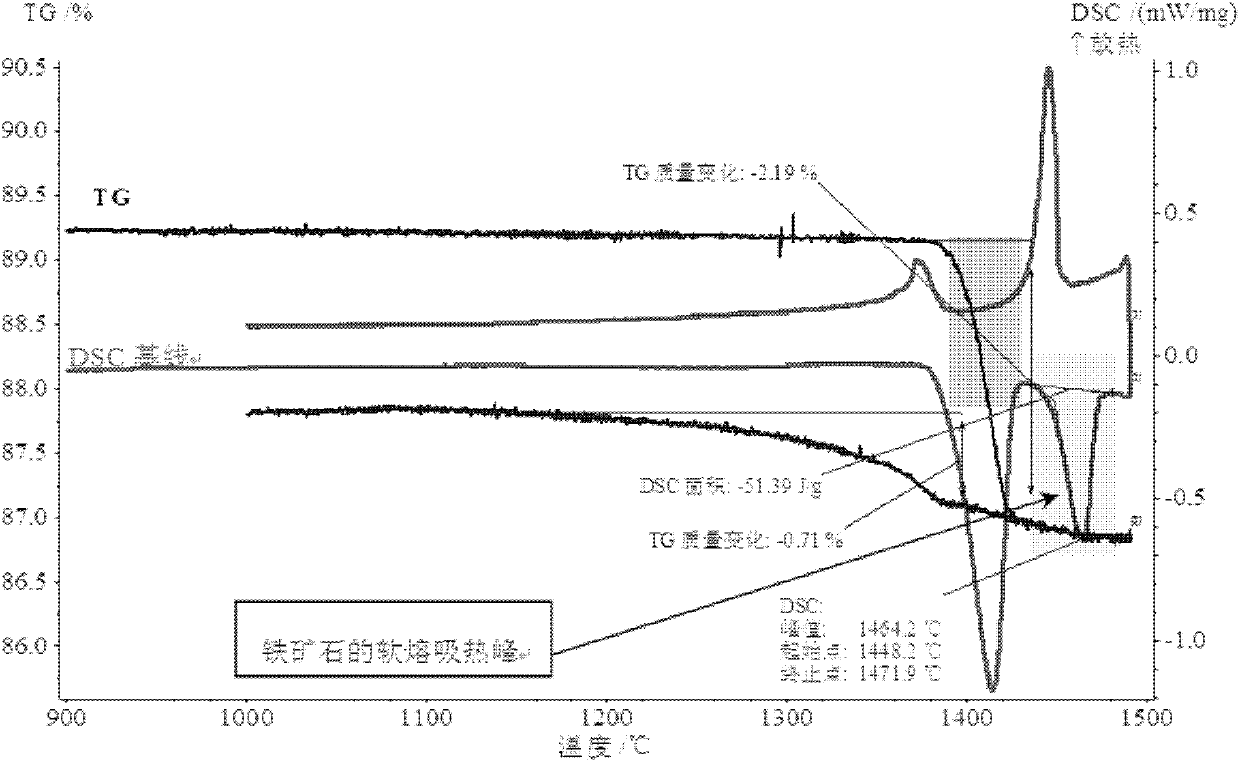

[0063] The test results are attached Figure 3-7 shown. attached by image 3 It is known that the reflow start temperature and reflow end temperature of Australian ores are lower than those of Brazilian ores, and the reflow temperature ranges of the two types of iron ores are not much different. attached Figure 4 It shows that, in general, the amount of liquid phase produced by the Australian ore reflow process is more than that produced by the Brazilian ore reflow process. attached by Figure 5 , 6 and 7, it can be seen that the iron ore reflow endothermic peak ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com