Simple clamping device for ultrasonic inspection of residual stress of steel rail

A technology of residual stress and ultrasonic testing, applied in the direction of measuring devices, measuring forces, instruments, etc., can solve the problems that the overall measurement of rail head and rail waist, mobile measurement and in-service measurement cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention is described in detail below:

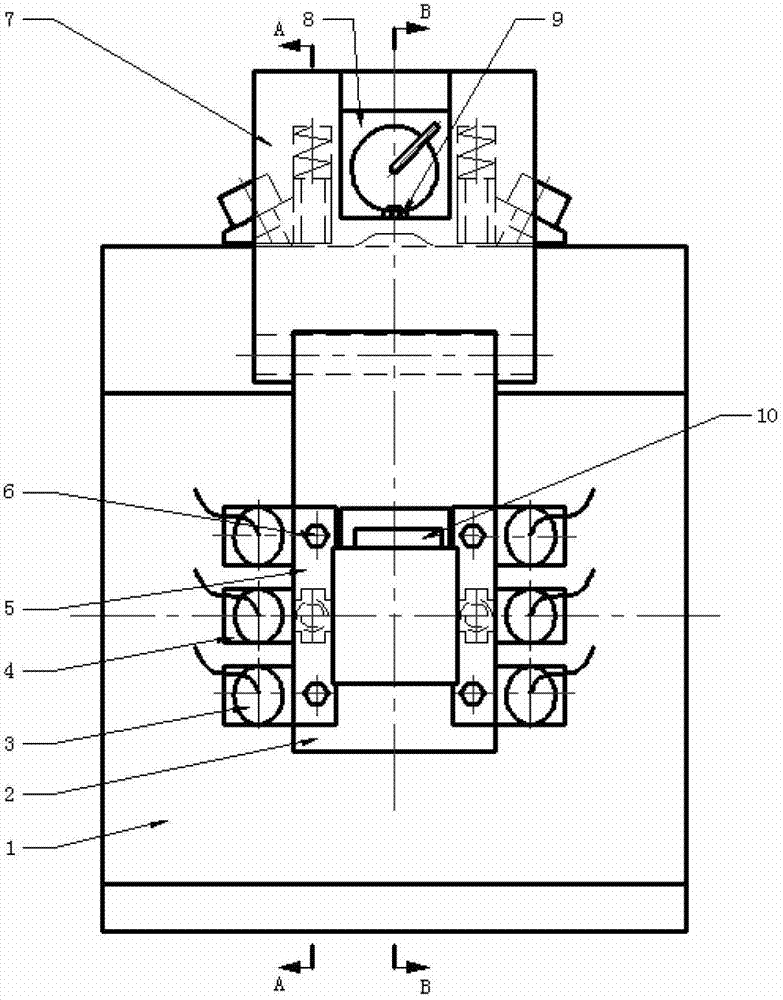

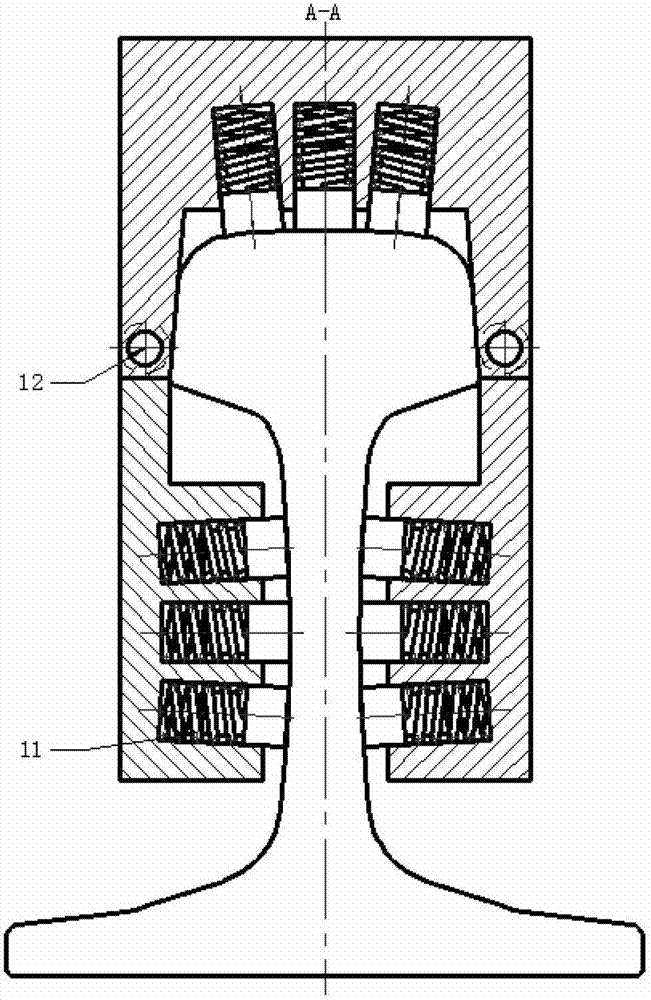

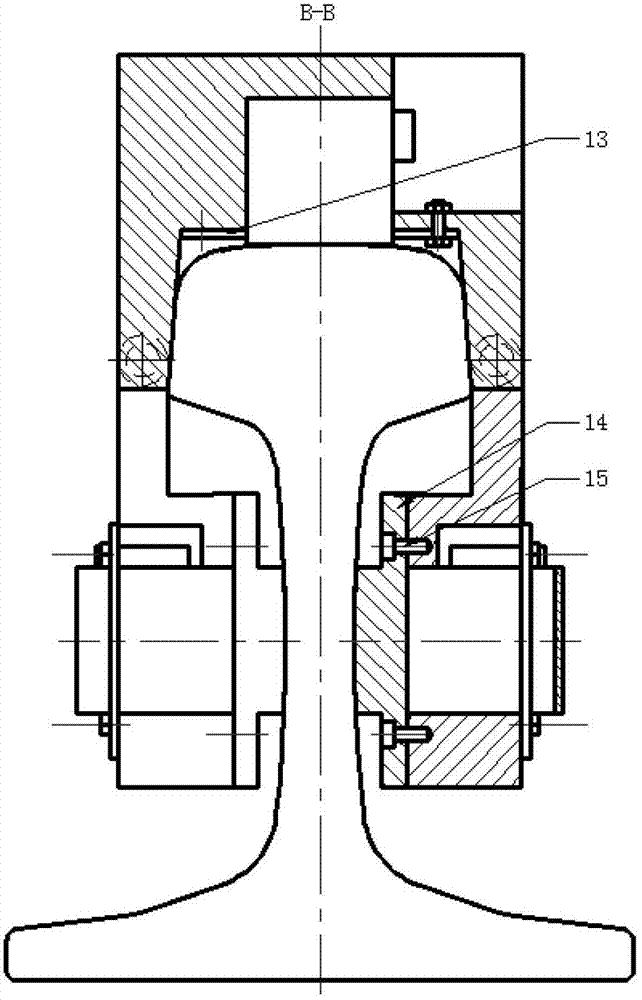

[0016] figure 1 Among them, the rail head magnetic seat 8 is embedded in the guide support frame 7, and the rail head magnetic seat is fixed on the guide support frame 7 by using the pressure plate 13 and the pressure plate bolt 9. Combine the probe 3 with the plexiglass wedge 4 , place the spring 11 in the groove in the plexiglass wedge 4 and install it in the corresponding installation hole of the guide support frame 7 . Place the assembled guide support frame 7 on the steel rail 1 to be tested stably. The magnetically conductive fixing plate 14 is fixedly connected with the mounting plate 2 by using the fixing plate screws 15, the rail waist magnetic base 10 is embedded in the mounting plate 2 and the bottom surface is closely attached to the magnetically conductive fixing plate 14, and the magnetic base cover plate 5 Fix and connect the rail waist magnetic base 10 and the strapping pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com