Assembling members using bearings to assemble rotating shaft in housing

A technology of assembly parts and rotating shafts, applied in the direction of bearing elements, rigid brackets of bearing parts, bearings, etc., can solve problems such as inability to maintain assembly performance, clamping or increased clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

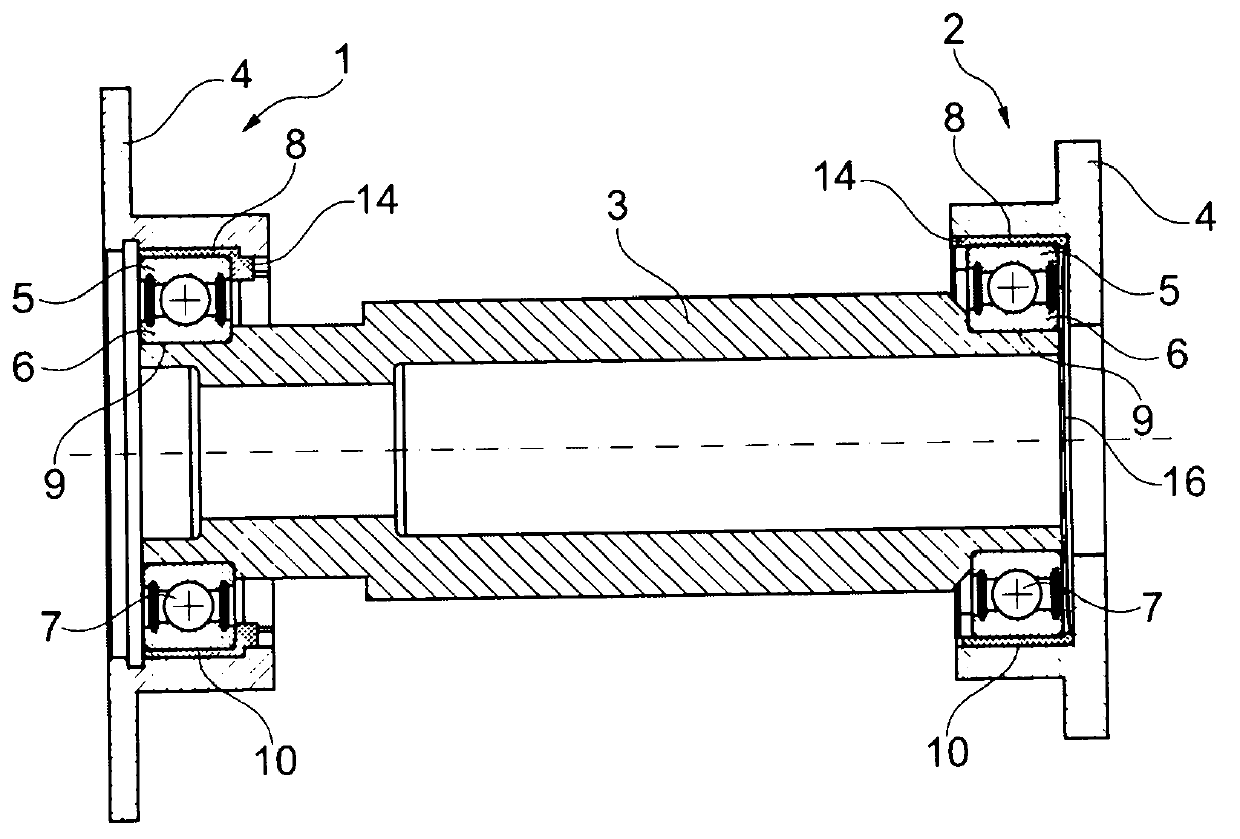

[0013] With reference to the drawings, the assembly 1, 2 in which the rotating shaft 3 is fitted in the housing 4 through bearings and the assembly including the rotating shaft 3 will be described below, wherein two axially spaced parts are mounted in the housing 4 through each bearing .

[0014] In particular, the rotating shaft 3 may be an axle wheel of an electric motor of a motor vehicle, wherein one part is locked in a housing 4 and the other part of said shaft is axially movable relative to the other housing 4 .

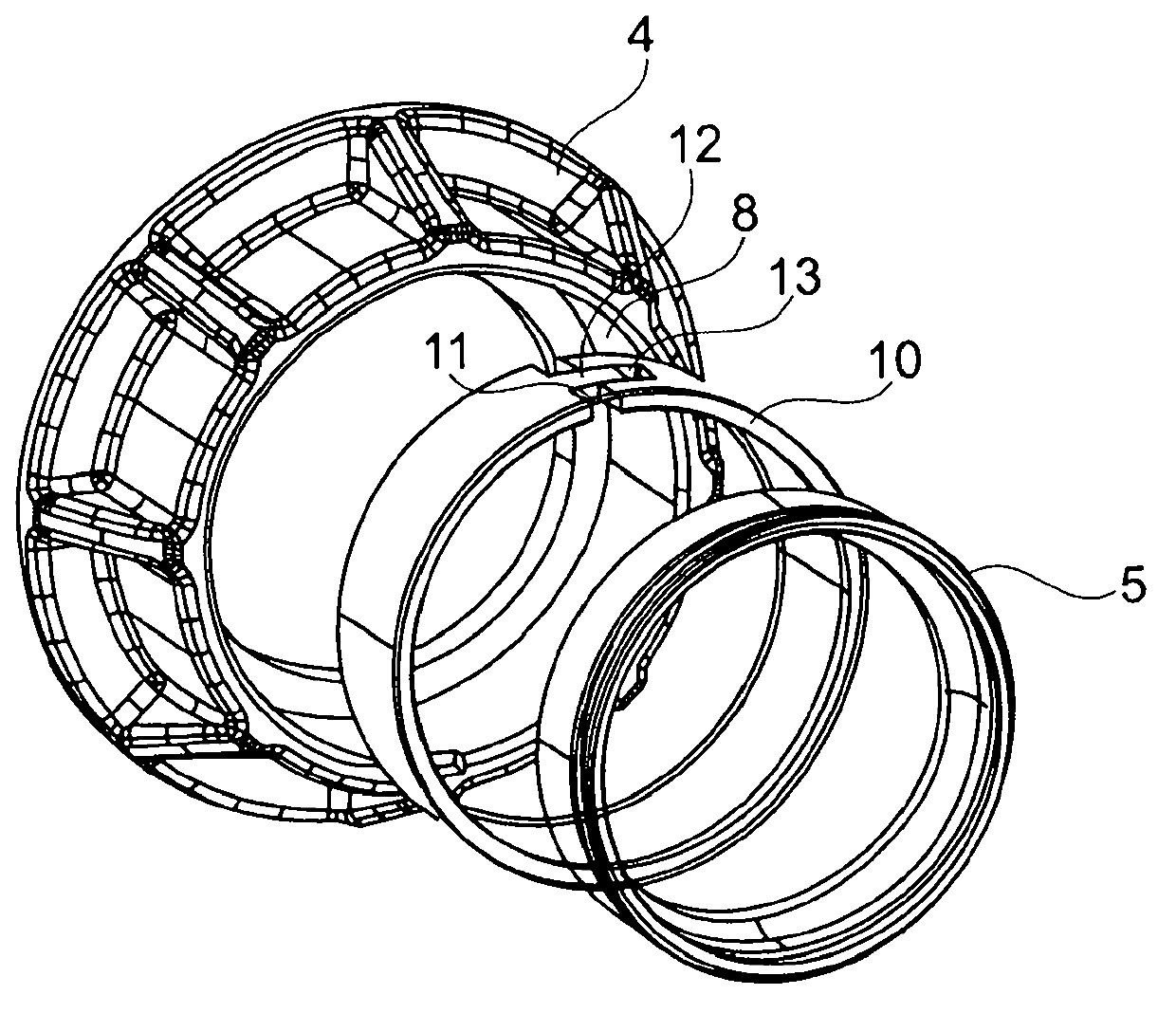

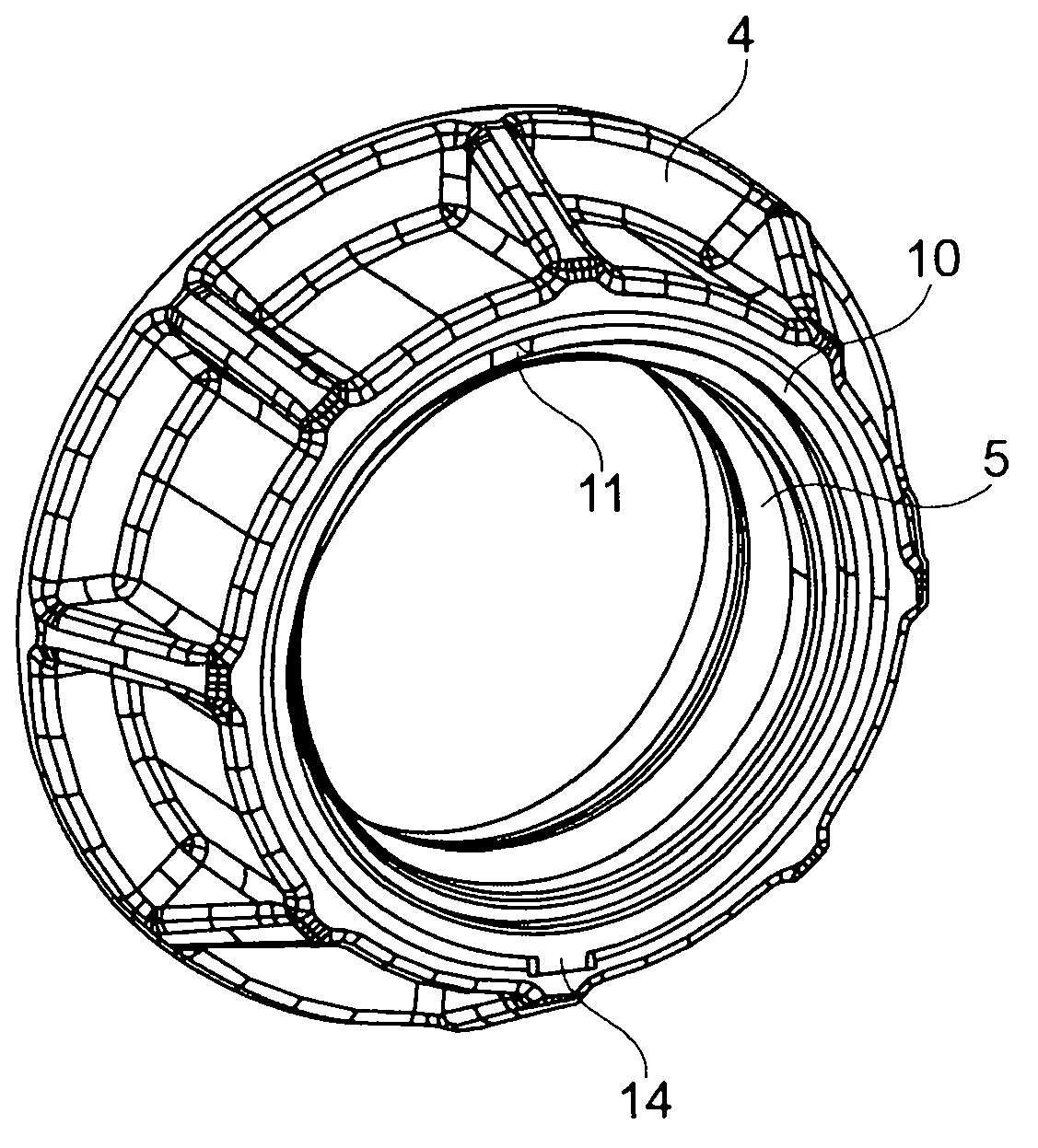

[0015] The bearing comprises a fixed outer ring 5 and a rotating inner ring 6 between which, in the embodiment shown, rolling elements 7 in the form of balls are arranged for enabling relative rotation of said rings .

[0016] The fittings 1, 2 have an annular accommodation defined between the inner bearing surface 8 of the housing 4 and the outer bearing surface 9 of the shaft 3, in which annular accommodation the bearing is arranged, clamped around the outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com